Yes Virginia, it can be done!

Having two good points rotors and one bad TCI rotor on hand I decided to try adding a rare earth magnet to one of the good points rotors and convert it to fire the TCI.

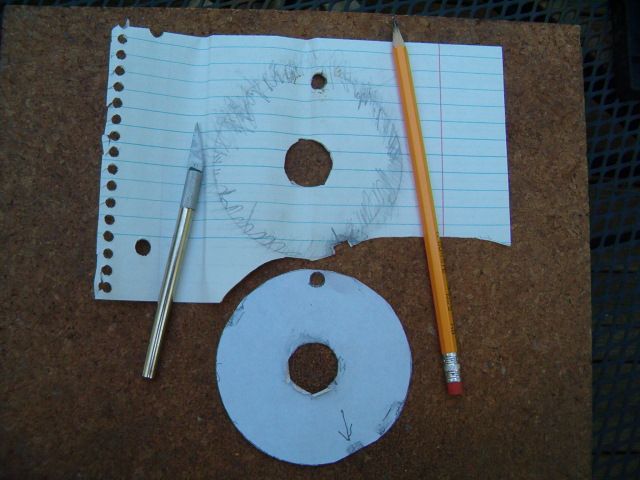

You need a TCI rotor to make a paper template for proper magnet placement.

Place a sheet of paper over the rotor, mark and cutout the threaded middle section so the template will sit flush on the rotor face.

Next place a 1/4"X1/16" rare earth magnet over the imbedded magnet. Trace around the magnet. Use the edge of a pencil and rub the outer edge of the rotor for boundarys sake. Rub the TDC mark on the rotor getting the timing mark.

Now remove the paper and carefully cut out the magnet location...exacto knife is good here. Trim around the outer boundary edge. Place the template on the points rotor lining up the timing mark on the paper template to the timing mark on the rotor.

You can see here where I trimmed the template a little at the timing mark so as to line the template timing mark to the rotor timing mark.

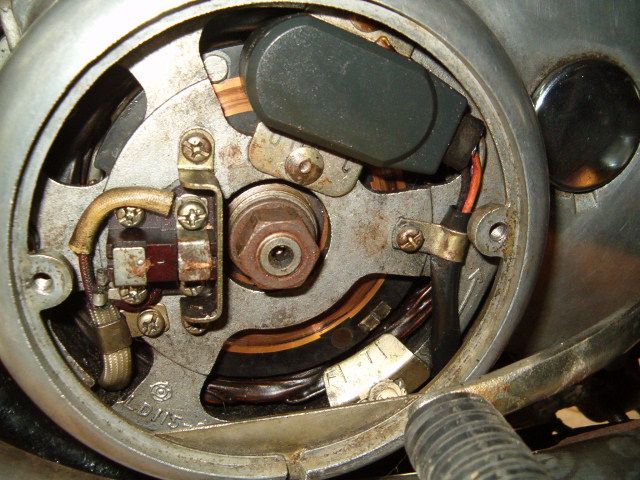

Mix up a little epoxy, I used JB Weld, and epoxy the magnet in its place. The magnet sits right on the outside edge of the outside slipring. This will keep the magnet out of the brush path and coincides with its placement on the stock TCI rotor. Let it set up good before using.

Does the polarity of the magnet matter? Not sure but I believe I transffered it directly from the bad rotor to the good, so the polarity would have been the same.

The rare earth magnets can be found on Amazon but you have to buy twenty to get one.

I have this installed on the '78 I picked up this past spring and it's working. Here you can see the magnet approaching the pickup at the top as the rotor timing mark approaches the timing tab on the stator.

In the process of putting this visual together I came across my original, very sophisticated template, slightly yellowed, as I did this experiment a few months ago but only got the bike truly running the other day.

Now to sort through these 38's and fix this low speed stumble.......dam mud dawbers.......

Having two good points rotors and one bad TCI rotor on hand I decided to try adding a rare earth magnet to one of the good points rotors and convert it to fire the TCI.

You need a TCI rotor to make a paper template for proper magnet placement.

Place a sheet of paper over the rotor, mark and cutout the threaded middle section so the template will sit flush on the rotor face.

Next place a 1/4"X1/16" rare earth magnet over the imbedded magnet. Trace around the magnet. Use the edge of a pencil and rub the outer edge of the rotor for boundarys sake. Rub the TDC mark on the rotor getting the timing mark.

Now remove the paper and carefully cut out the magnet location...exacto knife is good here. Trim around the outer boundary edge. Place the template on the points rotor lining up the timing mark on the paper template to the timing mark on the rotor.

You can see here where I trimmed the template a little at the timing mark so as to line the template timing mark to the rotor timing mark.

Mix up a little epoxy, I used JB Weld, and epoxy the magnet in its place. The magnet sits right on the outside edge of the outside slipring. This will keep the magnet out of the brush path and coincides with its placement on the stock TCI rotor. Let it set up good before using.

Does the polarity of the magnet matter? Not sure but I believe I transffered it directly from the bad rotor to the good, so the polarity would have been the same.

The rare earth magnets can be found on Amazon but you have to buy twenty to get one.

I have this installed on the '78 I picked up this past spring and it's working. Here you can see the magnet approaching the pickup at the top as the rotor timing mark approaches the timing tab on the stator.

In the process of putting this visual together I came across my original, very sophisticated template, slightly yellowed, as I did this experiment a few months ago but only got the bike truly running the other day.

Now to sort through these 38's and fix this low speed stumble.......dam mud dawbers.......

Last edited: