Since I've had the bike, I realized the timing range of the ATU was too large. When set at the F for idle, the timing would go well past the fully advanced mark. This was not safe for engine longevity, so I would compromise by moving the idle timing towards the TDC mark. Not the best solution!

grizld1 had mentioned a few years back that you can adjust the advancer weights to bring it back into range by peening. I thought I need to try that, but never got around to doing it. Well, finally this spring I took the weights out and peened the little tangs on the weights. grizld1 was right as usual.

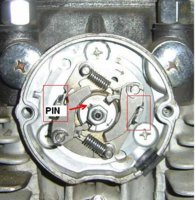

I found my tangs at 0.156". At first I only peened mine to about 0.161", but the timing range was still too expanded. OK, so I removed the weights again, and I decided that the answer is to keep peening the weights until there was a very tight fit in the slot in the "slotted disk". Yamaha made the slot in the slotted disk a specific size for a reason................it gives the correct timing range of 25 degrees (15 to 40 degrees).

So, I just peened some more and did trial fits until the tang fit in the slot was a very close fit but not too tight that it would bind. It ended up at 0.168". That's a 0.012" increase in width of the tang. Your bike may be different. Just peen and trial fit until you get that "tight" fit in the slot. My timing light now revealed I had correct timing at both idle and at 4000 rpm!!

Thanks grizld1 for a great tip...................a very simple fix.

grizld1 had mentioned a few years back that you can adjust the advancer weights to bring it back into range by peening. I thought I need to try that, but never got around to doing it. Well, finally this spring I took the weights out and peened the little tangs on the weights. grizld1 was right as usual.

I found my tangs at 0.156". At first I only peened mine to about 0.161", but the timing range was still too expanded. OK, so I removed the weights again, and I decided that the answer is to keep peening the weights until there was a very tight fit in the slot in the "slotted disk". Yamaha made the slot in the slotted disk a specific size for a reason................it gives the correct timing range of 25 degrees (15 to 40 degrees).

So, I just peened some more and did trial fits until the tang fit in the slot was a very close fit but not too tight that it would bind. It ended up at 0.168". That's a 0.012" increase in width of the tang. Your bike may be different. Just peen and trial fit until you get that "tight" fit in the slot. My timing light now revealed I had correct timing at both idle and at 4000 rpm!!

Thanks grizld1 for a great tip...................a very simple fix.

Attachments

Last edited: