Punkskalar

Hugh's HandBuilt

* For high resolution photos and details - this same post is on the Blog - http://hughshandbuilt.blogspot.com/2011/09/long-rod-xs650-crank-we-can-do-that.html

I've been wanting to build one of these for a good long while. I have a customer in the UK who has contacted me to build him a Long Rod XS650 Crank. I'll be using a set of CR500 Rods for this conversion.

Here you can see the difference between a standard 447 Rod from MikesXS, and a CR500 Rod from Hot Rods - much longer, and much better quality. Surprisingly, the Hot Rods are cheaper to get than MikesXS rods are as well

A better view of the rods for comparison.... CR500 Hot Rod on top, Stock HP replacement on bottom:

The Rod Pins that come with the 2 rods are a bit different as well. The 447 Rod Pin being shorter than the CR500 Rod Pin... I've machined the CR500 rod pin down to the proper length..

The CR500 Rod Pin is also hollow, which is a nice weight saving feature seeing as how the CR500 rods are slightly different in weight than the HP 447 Rods.

The small end of the CR500 Rod is much larger, and supports a roller bearing (which I think is a huge upgrade compared the stock setup). To utilize this bearing, the pistons will likely need to be modified a bit to fit the bearing width. Most folks are making bronze bushings to size, but I think I would keep the roller myself.. After seeing how abused the 2 stroke engines get by with, I see this as a nice touch

So I start with a very clean and degreased crank that has been fully disassembled.

I press in the Rod Pins, check them for square and fit, and then full TIG weld them into the flywheel.

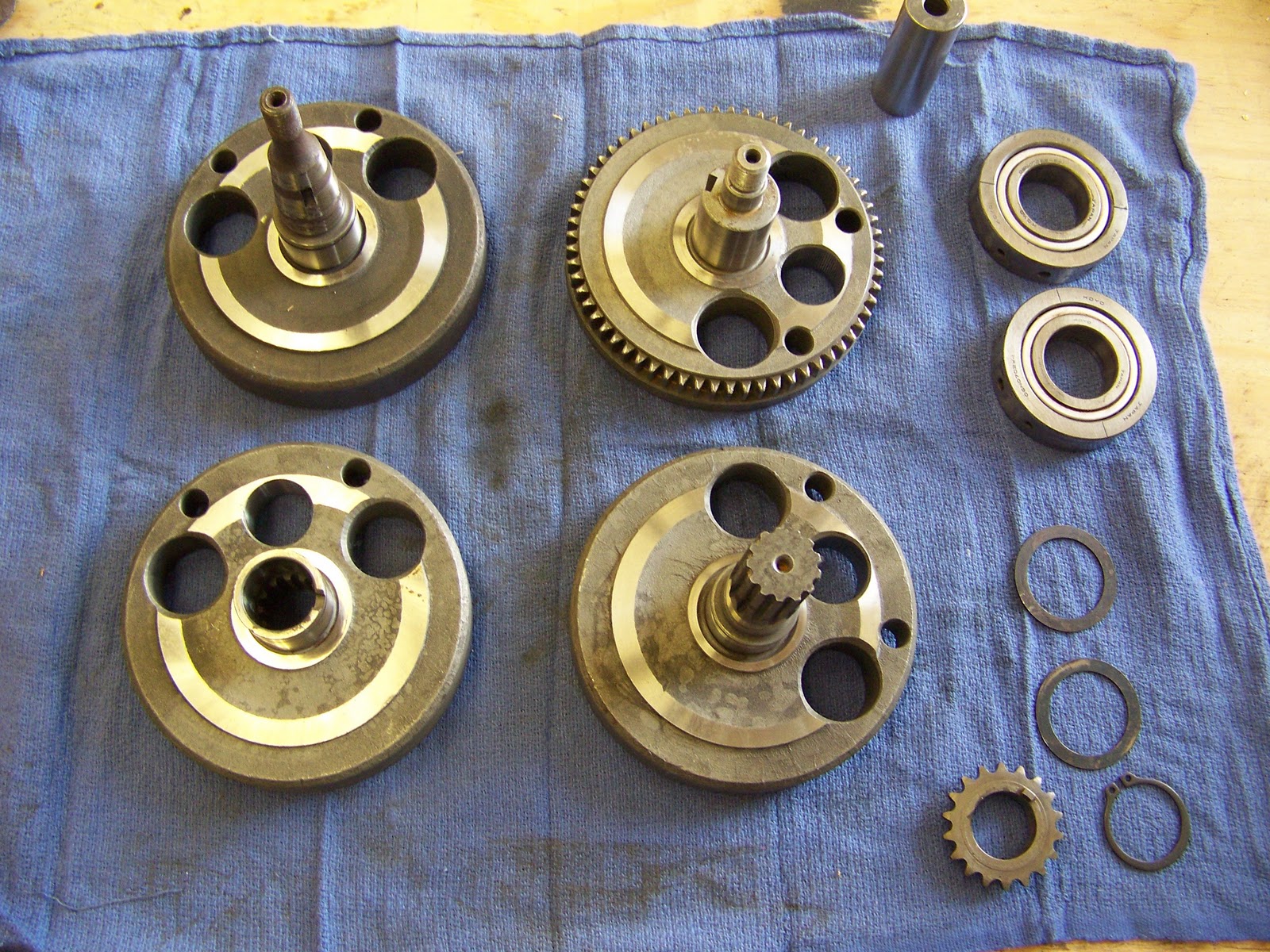

Fit up the shims and bearings...

Align the camchain sprocket and press the 2 halves together in the proper location (This crank is also being rephased, keep that in mind)

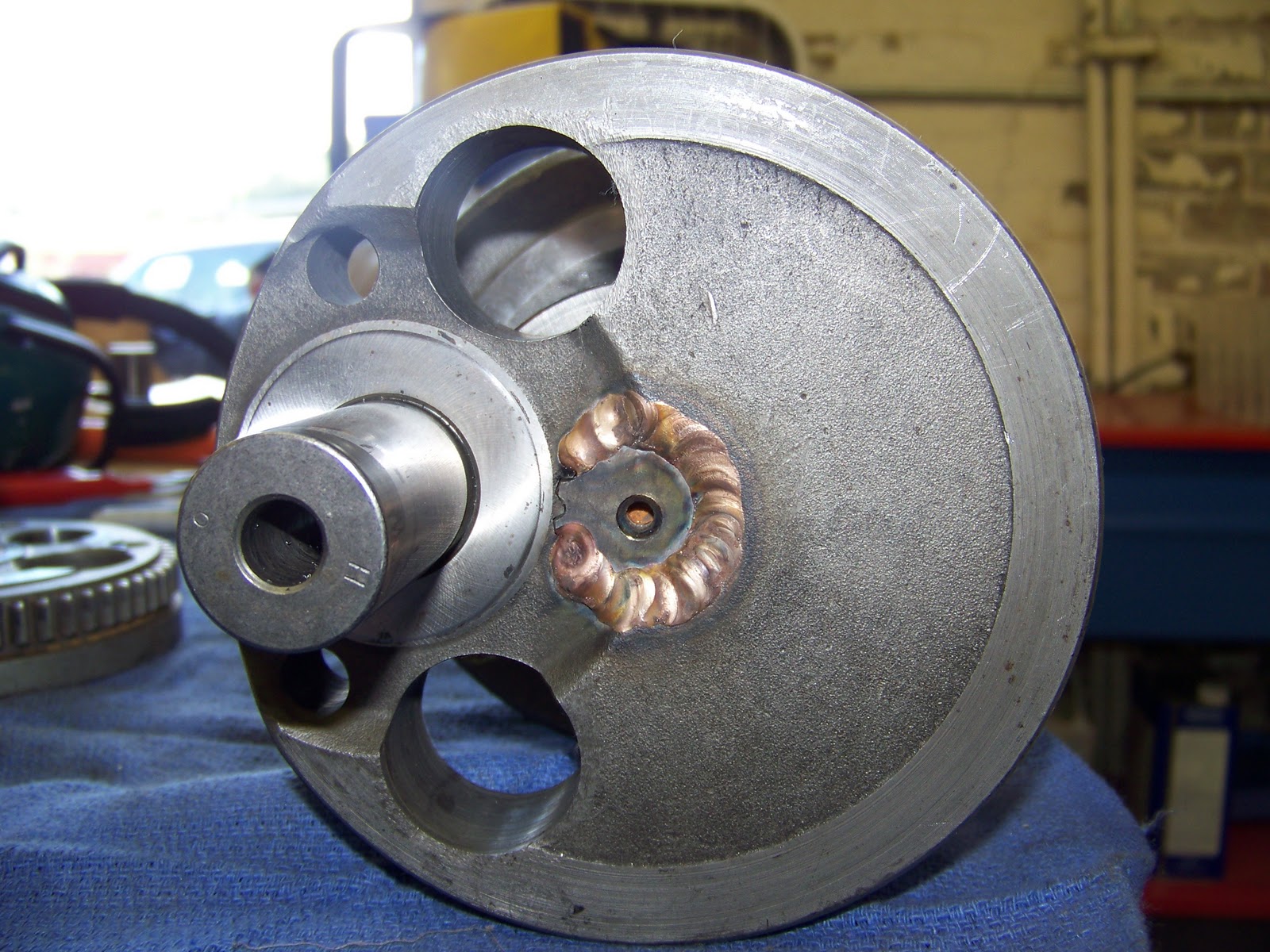

I ALWAYS weld a crank that is being used in a performance application. I see more crank failures from cranks walking apart than you could imagine. If you have problems with your charging systems and/or you are getting lots of aluminum shavings in your oil, then this is likely your problem... More information on that here:

http://hughshandbuilt.blogspot.com/2011/03/failed-cranks-why-to-properly-build-and.html

I see failures in stock engines just as often as in Big Bore engines, so do it once, and do it right...

This crank is welded in the center, notice I didn't weld right at the bearing surface for the rod thrust washer. Keeping the crank together is one thing, but you gotta keep those rods happy as well.

The CR500 Rods share the same width in the small end as the XS650 Rods. But, the XS650 Thrust Washers are narrower than the CR500 Thrust Washers, so I will be installing the XS650 Thrust Washers just as they were in the stock configuration. Keeping the crank operating in the cases as close to stock is important, and even something as small as .022" could get things really out of wack!

Stock XS650 Thrust Washer:

CR500 Thrust Washer:

If you kept the CR500 Thrust Washers, you crank would be almost .100" wider than stock, I don't think that would do your cases any favors...

Install the rods:

Get those outer flywheels on, true em' up and weld the pins... Sounds easy right? Getting the flywheels trued up properly is the toughest part of the job - I go more into depth on that in the last issue of RustyMetric Magazine (Online Magazine, only $1 for a download - check it out!)

Well there you have it, a really great looking setup for a long rod conversion. If you are thinking of doing this modification, know that you'll be modifying other parts of the engine to take advantage of this setup. Piston heights will have to be modified, clearances checked, etc... If you folks are lucky, maybe Jack will drop in and give some insight on getting the right pistons for the swap, but this one is headed to the UK for a guy that already has it figured out

Hugh

I've been wanting to build one of these for a good long while. I have a customer in the UK who has contacted me to build him a Long Rod XS650 Crank. I'll be using a set of CR500 Rods for this conversion.

Here you can see the difference between a standard 447 Rod from MikesXS, and a CR500 Rod from Hot Rods - much longer, and much better quality. Surprisingly, the Hot Rods are cheaper to get than MikesXS rods are as well

A better view of the rods for comparison.... CR500 Hot Rod on top, Stock HP replacement on bottom:

The Rod Pins that come with the 2 rods are a bit different as well. The 447 Rod Pin being shorter than the CR500 Rod Pin... I've machined the CR500 rod pin down to the proper length..

The CR500 Rod Pin is also hollow, which is a nice weight saving feature seeing as how the CR500 rods are slightly different in weight than the HP 447 Rods.

The small end of the CR500 Rod is much larger, and supports a roller bearing (which I think is a huge upgrade compared the stock setup). To utilize this bearing, the pistons will likely need to be modified a bit to fit the bearing width. Most folks are making bronze bushings to size, but I think I would keep the roller myself.. After seeing how abused the 2 stroke engines get by with, I see this as a nice touch

So I start with a very clean and degreased crank that has been fully disassembled.

I press in the Rod Pins, check them for square and fit, and then full TIG weld them into the flywheel.

Fit up the shims and bearings...

Align the camchain sprocket and press the 2 halves together in the proper location (This crank is also being rephased, keep that in mind)

I ALWAYS weld a crank that is being used in a performance application. I see more crank failures from cranks walking apart than you could imagine. If you have problems with your charging systems and/or you are getting lots of aluminum shavings in your oil, then this is likely your problem... More information on that here:

http://hughshandbuilt.blogspot.com/2011/03/failed-cranks-why-to-properly-build-and.html

I see failures in stock engines just as often as in Big Bore engines, so do it once, and do it right...

This crank is welded in the center, notice I didn't weld right at the bearing surface for the rod thrust washer. Keeping the crank together is one thing, but you gotta keep those rods happy as well.

The CR500 Rods share the same width in the small end as the XS650 Rods. But, the XS650 Thrust Washers are narrower than the CR500 Thrust Washers, so I will be installing the XS650 Thrust Washers just as they were in the stock configuration. Keeping the crank operating in the cases as close to stock is important, and even something as small as .022" could get things really out of wack!

Stock XS650 Thrust Washer:

CR500 Thrust Washer:

If you kept the CR500 Thrust Washers, you crank would be almost .100" wider than stock, I don't think that would do your cases any favors...

Install the rods:

Get those outer flywheels on, true em' up and weld the pins... Sounds easy right? Getting the flywheels trued up properly is the toughest part of the job - I go more into depth on that in the last issue of RustyMetric Magazine (Online Magazine, only $1 for a download - check it out!)

Well there you have it, a really great looking setup for a long rod conversion. If you are thinking of doing this modification, know that you'll be modifying other parts of the engine to take advantage of this setup. Piston heights will have to be modified, clearances checked, etc... If you folks are lucky, maybe Jack will drop in and give some insight on getting the right pistons for the swap, but this one is headed to the UK for a guy that already has it figured out

Hugh

Last edited: