-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

wes63bug

XS650 Enthusiast

Well heres mine, small but gets the job done, was an unfinished 2 car garage when i moved in, a little money and alot of junk later, lol.

down to 1 vw, time to put a bike table on the other side and get started.

down to 1 vw, time to put a bike table on the other side and get started.

pumps

XS650 Junkie

As it was completed. Now I have insulated , got lights, wired it, built a loft down the left and right sides at about 6 ft. (so I don't bump my head) front to back with the center left open.. Put a 5 ft piece of kitchen counter on the left inside the door to work on, with a vise. Two bikes, mower, weedeaters, ladders , rakes , shovels all that stuff hung up. I want to get a handy lift. Its 12ft wide as you look at it and 16 ft deep. And that's Peabody , my West Highland terrier. My white shadow.

I am Carbon

shade tree mechanic

Here is my shop building I built it myself about 4 years ago.. Did everything but the concrete work. 30 X 36 with 9' ceiling and Central HVAC...I just can't afford to run it much....

si that a 69 chevy i see there?

gemiller

XS650 Enthusiast

Completely unrelated but that VW bus is to die for.

Bike on the mac tools car lift bike holder conversion

Bike on the mac tools car lift bike holder conversion

Dang can't really find any good shots of the garage itself, it's always just the background of work lol. Its a 40x30 pole barn (my dads but i use it almost exclusively as long as I do his work too ) And I have a 1 bay at my house but its always full of bikes.

) And I have a 1 bay at my house but its always full of bikes.

Dang can't really find any good shots of the garage itself, it's always just the background of work lol. Its a 40x30 pole barn (my dads but i use it almost exclusively as long as I do his work too

si that a 69 chevy i see there?

Nope, That is my '65 Impala.... Here the '69.... It's not mine though. I'm just working on it for a guy, motor mounts, seat mounts, column, back bar, headers and such.. Everthing is custom on it.... Art Morrison Max G chassis.. Chassis cost more than what I built my shop for......

drog

XS650 Addict

Wow bobadame,that's an impressive shop! A CNC mill and lathe,too cool. Did you build that english wheel? I love it.I've never seen one with a hydraulic or air(can't tell from the pic) controlled top wheel,excellent design! And you have a '58 Buick too,don't see those much anymore. What size is that shop,looks huge? I'm impressed.

bobadame

XS650 Addict

The dark gray mill is a basic manual mill The CNC mill is way over in the corner, not really visible in the pictures. This building is 40'X 64' with a 14' wide side shed. The upstairs loft is 16' X 64'. There are a few project bikes up there and eventually there will be a PMS room on the north end for my sweety pie. It took me 27 months to the day to finish this thing. I hired a crew to pour the concrete, 58 yards I think it was and I hired a couple of guys to tape and finish the seams. I built and set the forms, set the steel, insulated the whole damned thing and hung the rock, screwed the roof on, painted the whole thing inside and out. My grand sons helped me raise most of the walls. I set the rafters, about 250 of them. Grandsons are afraid of heights. There's a mezzanine and a 2 post lift in there as well, and a shitter! At my age I really appreciate that. (You'll find out.)

The English wheel and the rest of the metalshaping machinery was all made in my old shop. The E wheel uses a #20 air brake chamber from an antique bus, another project that I hope to finish before they take my keys away.

The English wheel and the rest of the metalshaping machinery was all made in my old shop. The E wheel uses a #20 air brake chamber from an antique bus, another project that I hope to finish before they take my keys away.

drog

XS650 Addict

My error on the mill.Is that just a digital readout on it? I'm not a machinist,even though i do have an old (around 1930's) Logan lathe in my shop.I just use it for making bushings and other easy stuff.Primarily i focus on sheet metal repair and frame/bracket building.That is one big shop you have there.Mine is a lot smaller, 20X78 with 9' walls.I will post pix of it after i finish my latest re-arranging/cleaning.Thanks for the info on the shop and e-wheel! I'd like to know more about the bus,haha! I love old trucks,cars,etc. and have a few myself. My current project is a 53 Mack A model on a 1/2 ton chassis,running a built 454 backed with a Muncie M-21.I'm pushing 60 and can dig having a shitter nearby too,haha!

The English wheel and the rest of the metalshaping machinery was all made in my old shop. The E wheel uses a #20 air brake chamber from an antique bus, another project that I hope to finish before they take my keys away.

Bob,

Your metalworking equipment is awesome! Nice work on the English wheel, the "A" designed into the frame is a nice touch. And where'd you get the design for the planishing hammer? Looks neat

smurph

XS650 Addict

Well heres mine, small but gets the job done, was an unfinished 2 car garage when i moved in, a little money and alot of junk later, lol.

down to 1 vw, time to put a bike table on the other side and get started.

Nice VWs! I have a 64 Bug in sea blue I am looking at lowering this winter. I have a 62 bus as well but its pretty far gone (rusty), might just get rid of it as I don't think I will ever have the time or money.

Hi Guys,

I just *have* to get a digital camera! I have shots of the shop, but they are on film, and I haven't got a scanner. Sigh. Someday I'll step firmly into the 21st Century.....

Meanwhile, a short description: 24'x36' pole barn, insulated and wired for 220---it used to be our printshop, so there is plenty of power. Right now I have oil heat, but will be replacing it with wood very soon. There is a regular door, and an overhead door for bringing in bikes. It houses my bikes, parts of bikes, and tools. I've got a couple of drill-presses, including a wwII-vintage Delta floor model. I've got a compressor and gear, a big antique metal-cutting rig with a 6-foot cheater bar on it---my son loves that! Let's see, my son Bob has the gas bottles right now, but the arc welder is in the shed. A small 'fridge keeps things civilized in the summer. Scattered about are press pieces leftover from the printing days: most of a pre-war Multilith feeder and press, lots of lead type and widgets, some posters on the walls that we printed....and some vintage BSA/Triumph posters, one of which features Dick Mann on a Triple. I have a BSA clock on the wall. Let's see: eight or nine bikes, several BSA frames, about half a dozen BSA engines in various states of completion, a spare XS650 engine in pieces, various shelves full of boxes of parts and the occasional confused spider. The concrete floor has seen more than it's share of printing ink, solvent, oil, grease and gasoline. Outside I got my brother to build a 36'x12' overhang where I can park the sidecar bike, and store various things that don't count---like car parts and batteries and such.

Gee--that was long and doesn't do it justice, although I should mention that when I look at the pictures above I realize I've really got to clean the shed---like, RIGHT NOW!!

I guess I have to get a camera......

And of course, I love nothing better than digging about in someone else's shop...is there anything better??

, Excellent description of your Man Cave. I have a 14 by 20,space with a seprate office which is 9by9. Welding and paint work are done on the backside of my one acre property in a 8by18 little tool shed, if she goes up in flames at least its not connected to the house

, Excellent description of your Man Cave. I have a 14 by 20,space with a seprate office which is 9by9. Welding and paint work are done on the backside of my one acre property in a 8by18 little tool shed, if she goes up in flames at least its not connected to the house bobadame

XS650 Addict

Bob,

Your metalworking equipment is awesome! Nice work on the English wheel, the "A" designed into the frame is a nice touch. And where'd you get the design for the planishing hammer? Looks neat

Pixar. Just kidding. The pneumatic planishing hammer is similar to the ones sold by Neil Dunder. He has a company called Gitzit. I think his machines are very similar to the old Chicago Pneumatic machines. The goofy looking machine just this side of the bead roller is a dedicated shrinking machine. It's made out of stuff I had available at the time. The connecting rod is out of a '48 Ford flathead engine. The hammer just this side of the blue wheel is a Helve hammer. These mechanical machines all use various industrial DC sewing machine motors. Anyway if I can ever get started on it I plan to make a new tank and fenders for the XS project using some of these machines. It's good that I haven't been able to start on it yet because I still haven't decided on a style.

tigman175

XS650 Addict

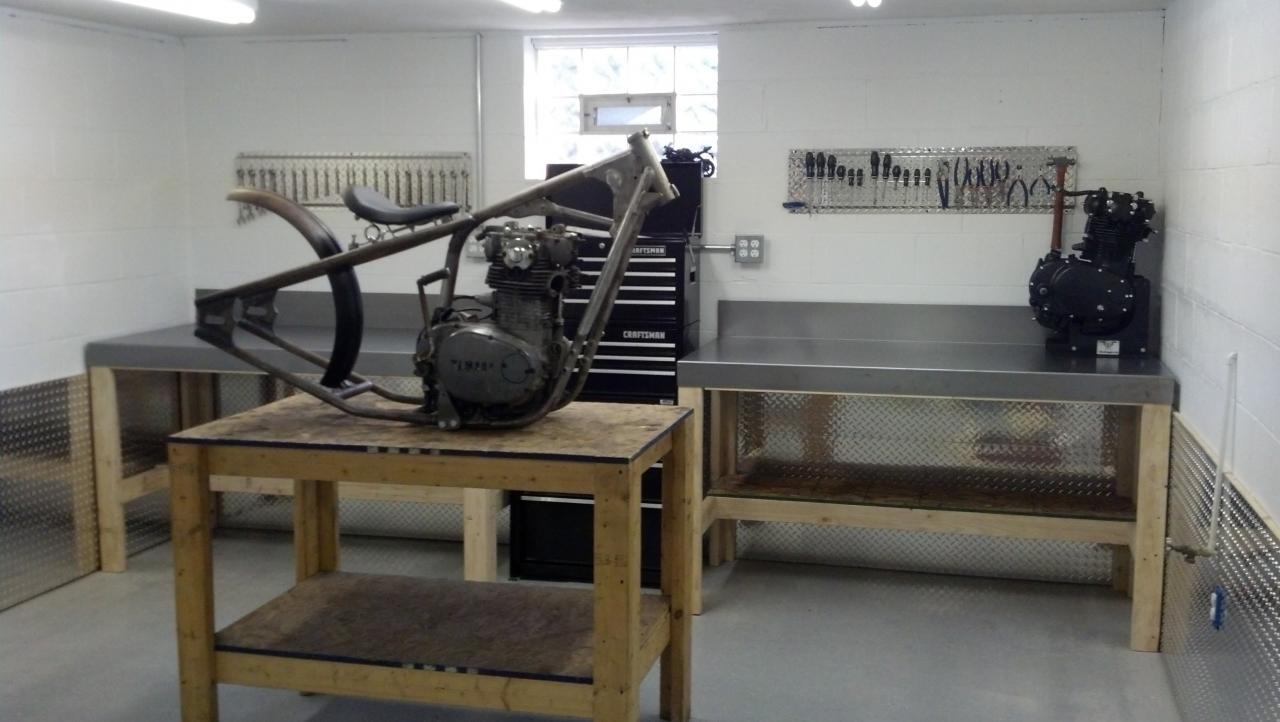

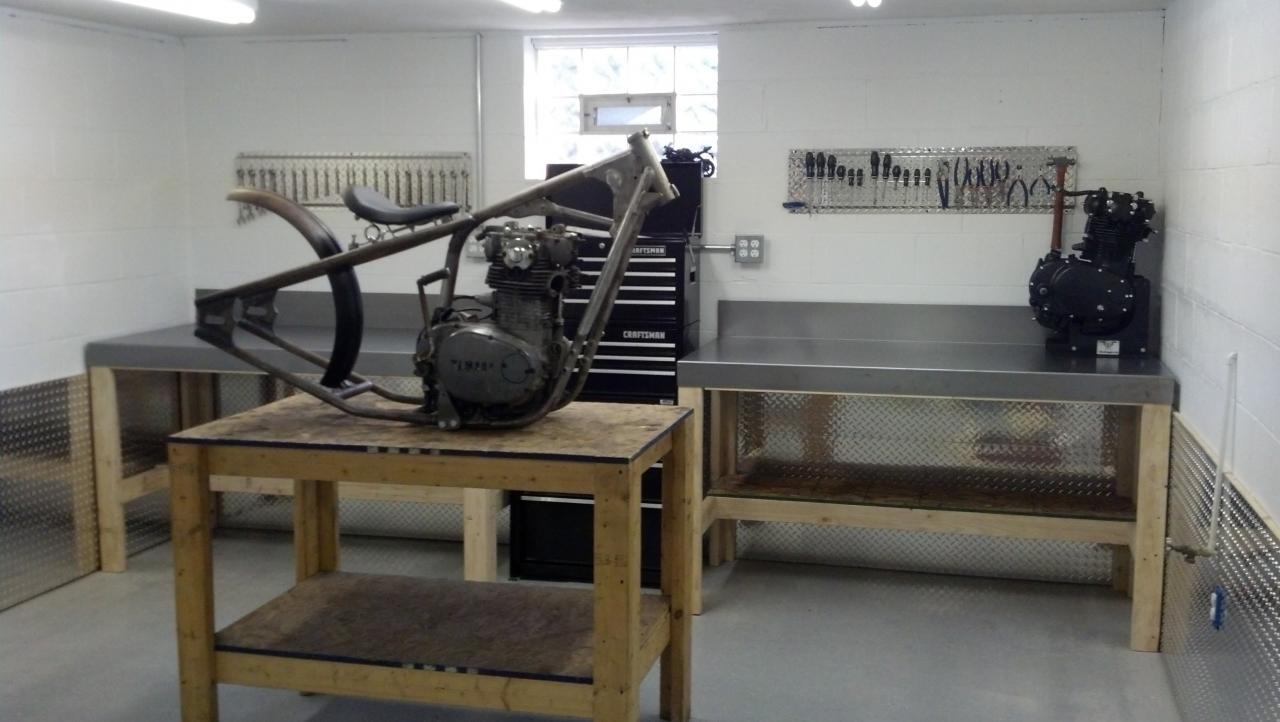

Just finished renovating the garage of the new house.....time to get building again!!

It looks clean, but all of my junk is behind me. Haha

It looks clean, but all of my junk is behind me. Haha

PetesPonies

XS650 Addict

I said I was building a new shop . . here it is

Paulrxs650

XS650 Enthusiast

Im in the small workshop!

bloodthirstysystem

XS650 Addict

my cramped shop/shed (screen printing that day). when renting you do what you can

Take Warning15

XS650 Addict

I build out of half the third stall in my parents garage.......i'm near tears right now

Yeah I'm working on the floor of a half garage full of my grandfather's life belongings. The front end of my bike is under a shelf. I can't even stand straight up in there. I'm getting used to it though!

My garage/shop has changed so much since this thread started 3 years ago. I'll try to post an update soon.