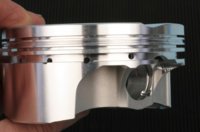

Looks like there is no anti-flutter groove on that piston so I would follow 5twins recommendations for the gaps. I was using 80mm converted to inches and got 3.149 I believe and that's how I got the gaps I gave to you. I have never ordered that kit before so the bore not be exactly 80mm, might be closer to 3.125 as you measured. And I believe you used .035" x bore instead of .006". That is why your gap number for the oil rail is .110", definitely way too much there.

As far as the tools needed, you can square up the ring an inch or so down in the bore using the piston as long as the dome doesn't travel all the way to the end of the piston itself. I have a ring squaring tool that is adjustable for different bores, comes in handy. Also as 5twins mentions, you may not even need to cut the rings. If you do, you can get a manual grinder from summit or other mail order facility. I use an electric one but I use it almost everyday and wouldn't waste the money for a one time use.

As for the rings, if one is wider as you mentioned then it will be hard to mess up the installation because they typically won't go in the bore if they are in the wrong groove. Top ring is usually made of a better material like ductile iron or steel and you will feel the tension difference when you install it. Bottom compression ring is usually cast and much weaker. Most rings will have a dot to indicate the top side when installing. If not, most top rings will either be non-directional or have a chamfer on the inside of the ring which faces up about 90% of the time. 2nd ring is usually a compression/oil control ring and will have a scraper (dykes or napier, you can view images online) and this scraper will be on bottom outside of ring (faces down).

There are a number of ways people like to "clock" rings so that the gaps are not all lined up when you install them. I generally clock them so that none of the gaps are over either skirt. That way you don't have to worry about which skirt is thrust side and anti-thrust side when there is an offset wrist pin. But to be honest, it doesn't make a whole lot of difference, the rings will sometimes rotate in the bore while it is running so just as long as they don't all line up when you install them you should be fine.

You can install the rings with a ring install/removal tool, there are several different designs on the market or you can roll them on by hand if you are careful. I am not a big fan of rolling on rings because they can get deformed in the process.

Good luck to you, if you need any more help just hit us up. It is nice when I can help someone out on this forum because I generally am learning since I know very little about these bikes.

Oh and thanks for the video, makes it a little easier to see what you are dealing with.