Hi.

First, let me explain what is going on. I'm in the middle of turning my 1979 XS650 Special in to a cafeish custom bike, and that includes building an electrical system from scratch around the Motogadget M-Unit. Took these pictures today:

(the polystyrene seat is there temporarily, trying to work out the shape)

Motogadget M-Unit and MMB 48mm (1 7/8") electronic speedo (gen II, model Target)

Now, to the point. My XS is an euro-spec, and the problem I have has to do with the field coil of the alternator. I got my self a solid state replacement regulator/rectifier unit from Electrosport (model ESR350, advertised as a straight replacement unit for the old points ignition models), because the original rectifier was all corroded outside and we all know that the mechanical regulator is pointlessly oldschool.

New

Old

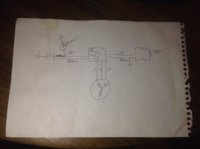

My field coil has two wires, a black one and a green one. In the old wiring the black one was tied straight to ground, and the green one went to the regulator. From that it is safe to guess, the old mechanical regulator was switching on and off the positive side of the field coil through the green wire. And that is all fine, but it was kind of surprising to read from the Electrosport manual (PDF file link) that the field coil's ground is switched on and off through the green wire with the new unit. So there lies my question, should I just connect the new unit's green wire to the black wire of field coil (both ground now) and connect a (ignition) switched positive to the green wire of the field coil?

Bottom one green, upper one black

After discovering my problem, I started searching for field coil electrical schematics on this forum, and found out that most North-American XS650's have the regulator switching the ground side of the field coil, I wonder why is it the other way around on euro-spec models.

Thanks,

Kustas

First, let me explain what is going on. I'm in the middle of turning my 1979 XS650 Special in to a cafeish custom bike, and that includes building an electrical system from scratch around the Motogadget M-Unit. Took these pictures today:

(the polystyrene seat is there temporarily, trying to work out the shape)

Motogadget M-Unit and MMB 48mm (1 7/8") electronic speedo (gen II, model Target)

Now, to the point. My XS is an euro-spec, and the problem I have has to do with the field coil of the alternator. I got my self a solid state replacement regulator/rectifier unit from Electrosport (model ESR350, advertised as a straight replacement unit for the old points ignition models), because the original rectifier was all corroded outside and we all know that the mechanical regulator is pointlessly oldschool.

New

Old

My field coil has two wires, a black one and a green one. In the old wiring the black one was tied straight to ground, and the green one went to the regulator. From that it is safe to guess, the old mechanical regulator was switching on and off the positive side of the field coil through the green wire. And that is all fine, but it was kind of surprising to read from the Electrosport manual (PDF file link) that the field coil's ground is switched on and off through the green wire with the new unit. So there lies my question, should I just connect the new unit's green wire to the black wire of field coil (both ground now) and connect a (ignition) switched positive to the green wire of the field coil?

Bottom one green, upper one black

After discovering my problem, I started searching for field coil electrical schematics on this forum, and found out that most North-American XS650's have the regulator switching the ground side of the field coil, I wonder why is it the other way around on euro-spec models.

Thanks,

Kustas

Last edited: