The ground strap runs from the battey - to a bolt right behind the battery the wire is about 6" long. There should be ground wires at the top engine mount under the gas tank that ground the black wires to engine and frame. I took a tested good VR and got somewhat random readings of at least a few hundred ohms green to black. I'm kinda guessing this is consistent with an unpowered transistor controlled circuit? Next up is testing green to black with red and black hooked to a battery.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Help: diagnosing overcharging.

- Thread starter DESTROYASAUR

- Start date

DESTROYASAUR

XS650 Enthusiast

I've allready cleaned and greased where the negative battery strap attaches to the frame. So that should be good. But I'll recheck it.

Is this the black wire that connects the engine to the frame? If yes it just goes from one side of the engine mount to the other. Should one end of it be attached where the coil mounts?

Here is the fading I'm getting from the green wire to the black wire at the reg plug. .6 ohms

This is the reading that I'm getting going from the same place on the reg plug to ground. For some reason I can only get engine or frame ground. When I try to do the negative battery lug I don't get continuity.

I've also noticed that I'm getting zero ohms between the black wire at the reg plug and frame, engine, or battery lug. I'm only getting bad continuity when the key switch is on. What's that about?

So for this next test I'm going to be jumping the black wire from the reg plug directly to the negative battery lug and the red wire from the reg plug to the posative terminal. And then I'm going to check if the green wire has continuity to ground like it should, i.e. 0 ohms?

Is this the black wire that connects the engine to the frame? If yes it just goes from one side of the engine mount to the other. Should one end of it be attached where the coil mounts?

Here is the fading I'm getting from the green wire to the black wire at the reg plug. .6 ohms

This is the reading that I'm getting going from the same place on the reg plug to ground. For some reason I can only get engine or frame ground. When I try to do the negative battery lug I don't get continuity.

I've also noticed that I'm getting zero ohms between the black wire at the reg plug and frame, engine, or battery lug. I'm only getting bad continuity when the key switch is on. What's that about?

So for this next test I'm going to be jumping the black wire from the reg plug directly to the negative battery lug and the red wire from the reg plug to the posative terminal. And then I'm going to check if the green wire has continuity to ground like it should, i.e. 0 ohms?

DESTROY.......................stop measuring with your ohmmeter. What you are measuring is meaningless, because you are measuring parallel paths in the circuits going to the rec/reg unit and other loads on the bike. This thread has gone off the rails, with incorrect VOM meter selector positions and some wrong assumptions.

You have two bad rotors. One is open circuit, so it cannot cause over charging. The other rotor has a ground on it, on the end of the rotor winding that is connected to the outer brush. Since the rec/reg unit (on 80 to 84 years only) feeds full battery voltage to the inner brush, full current will flow to the grounded rotor winding, and produce a strong magnetic field. . The regulator could not control, because the rotor has a constant ground on the outer brush end of the winding, and the result is over charging to 16 or 17 volts. I have re-read this whole thread and I edited my post #41 to reflect what I have found out.

Confusion abounds due to the 1970 to 1979 charging system, and the 1980 to 1984 charging system being totally opposite polarity in design.

If the rotor winding on a 1970 to 1979 gets a ground on it, you'll have low or no charging and may blow a fuse.

If the rotor winding on a 1980 to 1984 gets a ground on it, you'll have full constant charging (over charging) or partial charging, depending on where on the winding the ground occurs. In this case the ground is very near the outer slip ring end so 100% of the rotor winding is available to cause full over charging.

Clear as mud right!

Gary's used rotor should get things working.

Lessons learned.......................don't buy Chinese rotors from places such as Mikesxs.

Custom Rewind in Alabama, I believe is still in business , and they do excellent rewinding.

You have two bad rotors. One is open circuit, so it cannot cause over charging. The other rotor has a ground on it, on the end of the rotor winding that is connected to the outer brush. Since the rec/reg unit (on 80 to 84 years only) feeds full battery voltage to the inner brush, full current will flow to the grounded rotor winding, and produce a strong magnetic field. . The regulator could not control, because the rotor has a constant ground on the outer brush end of the winding, and the result is over charging to 16 or 17 volts. I have re-read this whole thread and I edited my post #41 to reflect what I have found out.

Confusion abounds due to the 1970 to 1979 charging system, and the 1980 to 1984 charging system being totally opposite polarity in design.

If the rotor winding on a 1970 to 1979 gets a ground on it, you'll have low or no charging and may blow a fuse.

If the rotor winding on a 1980 to 1984 gets a ground on it, you'll have full constant charging (over charging) or partial charging, depending on where on the winding the ground occurs. In this case the ground is very near the outer slip ring end so 100% of the rotor winding is available to cause full over charging.

Clear as mud right!

Gary's used rotor should get things working.

Lessons learned.......................don't buy Chinese rotors from places such as Mikesxs.

Custom Rewind in Alabama, I believe is still in business , and they do excellent rewinding.

The green wire is switched ground from the regulator. That's how the regulator turns the charging on and off, by switching the ground on and off. I'm not sure you would read a constant ground on that wire unless the regulator had it turned on. With the bike just sitting there not running, it probably isn't turned on.

Quote:

"And then I'm going to check if the green wire has continuity to ground like it should, i.e. 0 ohms?"

Why do you think the green wire should have a ground on it? The green wire voltage is controlled by the regulator, and will likely vary

from +2 volt to +7 volts as the engine rpm changes.

"And then I'm going to check if the green wire has continuity to ground like it should, i.e. 0 ohms?"

Why do you think the green wire should have a ground on it? The green wire voltage is controlled by the regulator, and will likely vary

from +2 volt to +7 volts as the engine rpm changes.

DESTROYASAUR

XS650 Enthusiast

Rock and roll. That is the kind of direct confirmation/affirmation that I needed to hear. I was hoping that would be the case with the rotor but I just wanted to be sure that was the only problem.

Obviously I know better now but before buying the rotor from mikes I had no idea those rotors/mikes had a bad reputation. Ironic as his rotors are actually more expensive than other better options. You live and you learn I suppose.

The green wire has no continuity to ground with the key switch off. When they key switch is on there is continuity going through the reg and coming out the black ground wire at the regulator plug. The part that I did not understand was why continuity between the black ground wire at the reg plug was getting inconsistent ohms to ground. Ive always been under the impression that a ground wire should have 0 ohms to ground. I also found it odd that there is more ohms between the black wire at the reg plug and the neg battery lug than there is between the black wire and the end of the strap that connects the lug to frame. Correct me if I'm wrong but that seems odd to me.

But no worries, I'll back off the multi meter for the time being and go ahead and re do the valves. If I run into problems with grounds after I get my rotor then I'll back back to drive Ye crazy. Personally I think It'll feel good going back to familiar/mechanical territory.

Obviously I know better now but before buying the rotor from mikes I had no idea those rotors/mikes had a bad reputation. Ironic as his rotors are actually more expensive than other better options. You live and you learn I suppose.

The green wire has no continuity to ground with the key switch off. When they key switch is on there is continuity going through the reg and coming out the black ground wire at the regulator plug. The part that I did not understand was why continuity between the black ground wire at the reg plug was getting inconsistent ohms to ground. Ive always been under the impression that a ground wire should have 0 ohms to ground. I also found it odd that there is more ohms between the black wire at the reg plug and the neg battery lug than there is between the black wire and the end of the strap that connects the lug to frame. Correct me if I'm wrong but that seems odd to me.

But no worries, I'll back off the multi meter for the time being and go ahead and re do the valves. If I run into problems with grounds after I get my rotor then I'll back back to drive Ye crazy. Personally I think It'll feel good going back to familiar/mechanical territory.

Coupla more things to check on your alternator.

Blow-up of your previous pic:

1- Your inner brush is damaged, will only make half contact. You could replace it, or squarely sand it down to full face contact. The current density is high in these brushes during full charge mode, and this would risk overheating of the slipring.

2. Ensure that all screws on the alternator housing don't protrude. Risk of contact, and damage to, the rotor face and sliprings, it they stick out too far...

Blow-up of your previous pic:

1- Your inner brush is damaged, will only make half contact. You could replace it, or squarely sand it down to full face contact. The current density is high in these brushes during full charge mode, and this would risk overheating of the slipring.

2. Ensure that all screws on the alternator housing don't protrude. Risk of contact, and damage to, the rotor face and sliprings, it they stick out too far...

I'll comment that I have found lots of BAD battery to frame ground straps, they get powdery grey corrosion where the wire fits in the lugs and no longer do a good job of grounding the battery. Remove and ohm out the strap wiggle the ends see if the reading changes. Question without my doing an RG style thread reread what indicates your battery is overcharging? Could you step back and shoot us pic of the whole bike?

Didn't you say that your sliprings were rough, and you thought your brushes were skipping? That must be the reason for that damaged brush, file it flat or replace it.

Scott

Scott

DESTROYASAUR

XS650 Enthusiast

Twomanyxs: Good advice about fixing up the brush. I'll definitely do that. As for the screws I've allready made very sure they don't protrude.

RG: the damaged slip rings are definitely why the brush is damaged. That's why I posted it. I'll definitely sand it down flat. They're still pretty long so it should be all good.

Gggary: I'll definitely test out the strap, but It seems In pretty good shape with no residue. My battery is overcharging because my rotor is grounding out. When it's at anything above idle the volts steadily rise up to 16 volts and that's when I shut it off before it fries everything. Anyway, here's some pictures of the bike.

RG: the damaged slip rings are definitely why the brush is damaged. That's why I posted it. I'll definitely sand it down flat. They're still pretty long so it should be all good.

Gggary: I'll definitely test out the strap, but It seems In pretty good shape with no residue. My battery is overcharging because my rotor is grounding out. When it's at anything above idle the volts steadily rise up to 16 volts and that's when I shut it off before it fries everything. Anyway, here's some pictures of the bike.

Quote:

"The green wire has no continuity to ground with the key switch off. When they key switch is on there is continuity going through the reg and coming out the black ground wire at the regulator plug. "

When the key is switched on, the regulator sees battery voltage of perhaps 12.5 volts. The regulator circuit will see this as very low voltage and will adjust the voltage on the green wire to a very low voltage, maybe +1 or +2 volts, close to ground potential. What you are seeing appears to be normal to me.

The black wire at the rec/reg connector plug must be a good ground connection. That black wire runs into the wiring harness, and there is always a possibility that some PO has changed the wiring in the past. Also any bullet connections or other connections along the common black wire in the harness, could have corrosion which means high resistance. When you measure from the black wire at the reg connector to the battery negative terminal, it must measure less than 0.5 ohms. Cheap meter leads can give bad readings. Lets say your meter leads are 0.7 ohms. If you measure 1.2 ohms, then subtract 0.7 ohms equals actual reading of 0.5 ohms.

"The green wire has no continuity to ground with the key switch off. When they key switch is on there is continuity going through the reg and coming out the black ground wire at the regulator plug. "

When the key is switched on, the regulator sees battery voltage of perhaps 12.5 volts. The regulator circuit will see this as very low voltage and will adjust the voltage on the green wire to a very low voltage, maybe +1 or +2 volts, close to ground potential. What you are seeing appears to be normal to me.

The black wire at the rec/reg connector plug must be a good ground connection. That black wire runs into the wiring harness, and there is always a possibility that some PO has changed the wiring in the past. Also any bullet connections or other connections along the common black wire in the harness, could have corrosion which means high resistance. When you measure from the black wire at the reg connector to the battery negative terminal, it must measure less than 0.5 ohms. Cheap meter leads can give bad readings. Lets say your meter leads are 0.7 ohms. If you measure 1.2 ohms, then subtract 0.7 ohms equals actual reading of 0.5 ohms.

DESTROYASAUR

XS650 Enthusiast

Alright, so I have zero ohms going from the black wire at the reg plug to the negative battery lug, but only when the key switch is turned off. The second I turn that switch on I'm get varying ohms, anything from 30-140 ohms, to every single place I check. Is that normal? If yes could somebody explain why. I'm not understanding how a closed circuit with no resistance or relays can suddenly have a lot more resistance when you add voltage moving through the system.

If having high ohms with the key switch on is not normal then I'm a bit lost for what to do because I'm getting a diferent reading every time I move one of my leads, even if it's back to a previous position. (This is with one lead at the black wire on the reg plug)

RG, I've got my meter specked out. The ones I'm using for these test reidys .5 ohms high. I've allready gone through and opened every connector I could find, cleaned, and greased them. They should be all good,

Thanks again for the explanations guys! I appreceate it immensely.

Wolfram

If having high ohms with the key switch on is not normal then I'm a bit lost for what to do because I'm getting a diferent reading every time I move one of my leads, even if it's back to a previous position. (This is with one lead at the black wire on the reg plug)

RG, I've got my meter specked out. The ones I'm using for these test reidys .5 ohms high. I've allready gone through and opened every connector I could find, cleaned, and greased them. They should be all good,

Thanks again for the explanations guys! I appreceate it immensely.

Wolfram

All resistance (ohms) tests MUST be done with NO currents and voltages in the system under test. The meter supplies its own currents/voltages in order to sense what's out there. Externally supplied currents/voltages foul-up the meter's reading, and can destroy the meter.

The moment you start supplying voltages/currents (like when turning a switch on), switch the meter(s) to measure voltage...

The moment you start supplying voltages/currents (like when turning a switch on), switch the meter(s) to measure voltage...

DESTROYASAUR

XS650 Enthusiast

Well there you go. Seems like everything is probably totally okay and I should never be alowed near a multi meter That rotor should be here in the next few days. I'll post and tell ye guys how it goes.

Thanks again!

Wolfram

Thanks again!

Wolfram

OK, so there you have it, black wire test sounds normal. That black ground wire in the reg/rec plug on the harness supplies the ground to both the reg and rec in the unit. The black wire in the harness runs up to around the coil where it exits the harness and usually grounds to the frame on one of the coil mounting bolts. In the harness, many other black ground wires from other components connect into it.

That short black ground wire you found on top of the motor has nothing to do with the harness ground wire. It's simply an additional ground for the motor itself. The motor grounds through each of it's mounts but also has that little wire added. On the earlier points models, the condenser pack mounted on that top motor mount. That's what the 2 threaded holes were for. That little ground wire ran to the condenser pack. When the electronic ignition came along and the condenser pack was eliminated, Yamaha left the little ground wire in place.

That short black ground wire you found on top of the motor has nothing to do with the harness ground wire. It's simply an additional ground for the motor itself. The motor grounds through each of it's mounts but also has that little wire added. On the earlier points models, the condenser pack mounted on that top motor mount. That's what the 2 threaded holes were for. That little ground wire ran to the condenser pack. When the electronic ignition came along and the condenser pack was eliminated, Yamaha left the little ground wire in place.

Interesting 5twins, on my SH the wire just goes from one side of the top engine mount to the other. I sometimes wonder what it is really doing??

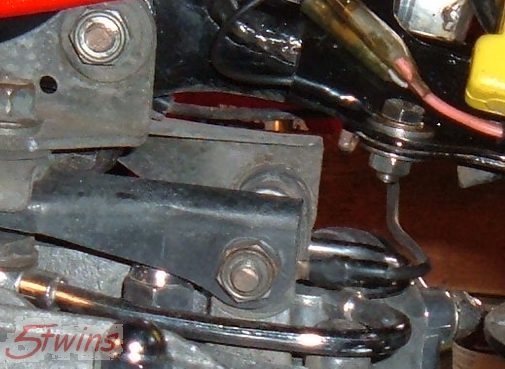

It should run down to the motor itself. It gets sandwiched between the lower right top mount and the engine casting .....

It may originally have been insurance for the condenser pack grounding. Honestly, I can't say for sure why Yamaha did it, but I always leave it in place. It's still there even though I run a Pamco now.

It may originally have been insurance for the condenser pack grounding. Honestly, I can't say for sure why Yamaha did it, but I always leave it in place. It's still there even though I run a Pamco now.

Perhaps it was to give a direct ground to the topend so as to avoid a path via the crank/conrod bearings should the head become electrically isolated due to the rubber washers and cylinder base gasket. Potentially current through a bearing could cause erosion - Perhaps???

^The head is connected to the frame too, through the top mount. Maybe at assembly there was paint on the frame and in the hole there. Theoretically the head could be insulated, so probably the wire covers that.

Your use of the OHM meter......Your pictures make it seem that you are lightly holding the probes to everything that you test......that won't work and will give you readings all over the scale. You need to almost drill those leads into everything that you test and hold them there with some force, then take the LOWEST reading from the OHM meter. Certain things you don't want that drill mark in, like a part of the slip ring on the rotor where the brush passes over.

Again, dielectric grease.......grease between the connections is defeating your purpose of getting a good connection. If you insist on using the grease, smear it around the connector after the connectors are plugged together or fastened where they go.

Scott

Again, dielectric grease.......grease between the connections is defeating your purpose of getting a good connection. If you insist on using the grease, smear it around the connector after the connectors are plugged together or fastened where they go.

Scott