Sometimes you make forward progress, sometimes a step backward. Coil and mounts will be relocated for sure.

So many issues, venting plan is decided and nearly complete. Mounting scheme - Rubber fittings on the frame, rubber cups on the tank...

Petcock and fuel heights VS Carb fuel inlet heights are a bit of a concern... Considering a remote valve. Remote fuel filter a must, but very little space available. Quick release lines I like to use on all my bikes, not sure there is space for these either... (And the ones I have are too large of hose diameter...)

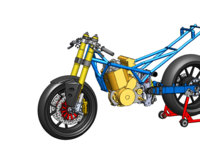

Photos from this weekend.

Hard to see, but trying to decide petcock location. Currently considering a remote mount/bracket mounted valve.

Two strong location contenders:

Deep under the tank at the rear and a bit forward by the head.

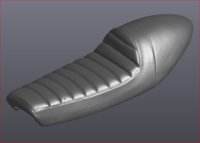

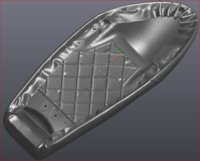

Working with my friend Tony. He's really doing all the work on the tank. The rear section (bottom side of the tank) was decided to leave it in place so the rest of the shell maintains some kind of structure. The back section there will add about 0.3gal of gas. A few holes added. Almost could function as a baffle...

Tony is shaping and fitting the pieces together that will form the bottom portion of the tank. The heat outside yesterday at 5:15pm was only 112F (44C). Not sure how hot it got today. Definitely too hot to be doing this kind of work inside a garage! Very painful, slow process.

Bottom section is now together and will be removed again, as a single piece. Then the vent, fuel feed tube, etc - will be added...

The tank is really starting to come together. A few details yet to work out though...