MadeThatMyself

XS650 Enthusiast

I removed my sump filter last night to find the classic torn mesh on what appears to be the original filter. After doing some forum research, it looks like the MikesXS filters seem to work, but really aren't any more durable that the OEM ones that have been repaired with JB weld, sheet metal, etc.

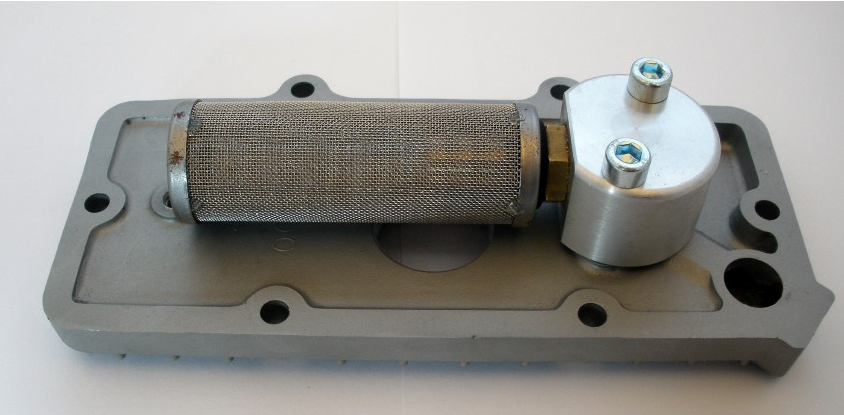

Then I stumbled upon this filter from Heiden Tuning...

Most of the posts about it were older and said that the product was too new, had no reviews, no information on performance/longevity...

I am curious if anyone has run this filter for a while and has any opinions, positive or negative? Is there a magnetic element to this filter? I noticed Heiden also sells a magnetic drain plug. I am not sure if the OEM plug is also magnetic. I didn't think to look when I took it apart.

Then I stumbled upon this filter from Heiden Tuning...

Most of the posts about it were older and said that the product was too new, had no reviews, no information on performance/longevity...

I am curious if anyone has run this filter for a while and has any opinions, positive or negative? Is there a magnetic element to this filter? I noticed Heiden also sells a magnetic drain plug. I am not sure if the OEM plug is also magnetic. I didn't think to look when I took it apart.