Thank you Peanut. I thought the vacuum variation with throttle position might not be reliable enough, but cars did use it for years. I guess advance mapped against rpm is the real answer but a more complex design issue for me to tackle.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boyer and Pamco Ignition

- Thread starter 650Skull

- Start date

-

- Tags

- electrical ignition pamco

Quite cheap at £42.

Attachments

gggGary, thank you for the references. Going through them I picked up a reference to the XS1100 having vacuum advance, something I did not know. So maybe there is a route to avoiding timing degree mapping with a microprocessor.

Rasputin, your entry above reinforces my view regarding the ease of access to ignition units and the difficult step being how to deal with engine advance. Perhaps there is some mileage to go with vacuum sensing ICs.

Thank you everyone - Hijack over for now?

Rasputin, your entry above reinforces my view regarding the ease of access to ignition units and the difficult step being how to deal with engine advance. Perhaps there is some mileage to go with vacuum sensing ICs.

Thank you everyone - Hijack over for now?

In my honest opinion there isn’t a lot wrong with mechanical ARU, especially Japanese ones.

This together with an electronic trigger would prove quite acceptable. I have an old Piranah optical unit on my 400/4 with the original ARU, been on there best part of 25yrs. I did have trouble when one coil went to ground through the centre bar and blew the fuse, once I found out what was blowing the fuse, fitted a replacement coil, back to normal.

Sometimes we strive for something that isn’t there.

This together with an electronic trigger would prove quite acceptable. I have an old Piranah optical unit on my 400/4 with the original ARU, been on there best part of 25yrs. I did have trouble when one coil went to ground through the centre bar and blew the fuse, once I found out what was blowing the fuse, fitted a replacement coil, back to normal.

Sometimes we strive for something that isn’t there.

Surely, a TPI signal combined with rpm input in a digital timing map will give the same result as mechanical advance combined with a vacuum signal? In both cases, less vacuum/more throttle should be used to retard timing, while higher rpm generally increase timing.

I believe using a vacuum input was more suited to analog/ mechanical systems, while TPI seems easier to use with digital systems.

I believe using a vacuum input was more suited to analog/ mechanical systems, while TPI seems easier to use with digital systems.

I was gapping my plugs .080 back in the seventies,open'em up till it misfires or performance drops. On worn out plugs you'd see .100 plus and still firing away. The HEI is a damn good ignition system.Oh, that's nice. I knocked up a twin-HEI unit for my Suzi GS a couple of years ago, using the standard ignition triggers and mechanical advance. It worked well. Never tried the extreme gapping, though. A google for "HEI ignition for Kawasaki" will find the site I got the info from.

Anyone heard of Carmo Electronics?

https://www.carmo.nl/index.php?main_page=index&pg=home&zenid=dnkvt8ntpteng72kunpedceck3

They have a range of ignition systems that seem based around a few modules programmed for specific models i.e. each with a slightly different advance curve. The ignitions are mainly classed as plug and play with the correct mounts and sockets to mate with the original bikes hardware. My interest is the Virago version at a cost of approximately £340, but this price does include the coils as well.

Edit: The cost is just for the ignitor box as it is a plug n play system using existing coils.

This company also repairs the old TCI units.

Does anyone know of their reliability? I am hoping Peanut has some UK views on this company.

Thank you.

Edit: XS650 system - https://www.carmo.nl/index.php?main...t8ntpteng72kunpedceck3&keyword=xs650+ignition

https://www.carmo.nl/index.php?main_page=index&pg=home&zenid=dnkvt8ntpteng72kunpedceck3

They have a range of ignition systems that seem based around a few modules programmed for specific models i.e. each with a slightly different advance curve. The ignitions are mainly classed as plug and play with the correct mounts and sockets to mate with the original bikes hardware. My interest is the Virago version at a cost of approximately £340, but this price does include the coils as well.

Edit: The cost is just for the ignitor box as it is a plug n play system using existing coils.

This company also repairs the old TCI units.

Does anyone know of their reliability? I am hoping Peanut has some UK views on this company.

Thank you.

Edit: XS650 system - https://www.carmo.nl/index.php?main...t8ntpteng72kunpedceck3&keyword=xs650+ignition

Last edited:

C5 igntions for virago and there not cheap.

http://www.c5ignitions.com/motorcycle-ignitions.html

http://www.c5ignitions.com/motorcycle-ignitions.html

Thank you Jack, certainly expensive. They are cam mounted where as the Carmo is crank mounted. Mind you I was happy with the cam mounted Boyer on the XS650.

It's a shame that Probe ignitions closed it's doors. Was crank triggered with several advance curve adjustments. Member Griz has one on his XS,be nice to copy the circuitry on it .

Howdy, Jack! Probe Engineering is still alive and well, but Mark Whitebook made the decision to drop production of motorcycle ignitions because they were costing him money. Probe is a great design, but it's a camshaft driven system. The timing plate is very robust and sits in the bottom of the ignition housing where it belongs.The rotor is secured to the camshaft by an expanding collet--much more sensible than threading it onto a chunk of all-thread, Boyer style. Right, the advance curve is programmable, there's a choice of rev limiter settings, and there's an LED on the igniter box that lets you ballpark static timing before you fire up and finish the job with the strobe. Mark wrote several pages of instructions to guide even the most clueless installer. There's no way to find out what's in the igniter box without destroying it--not gonna go there, sorry!

shotgunjoe

XS650 Hunter

What about adapting a Ultima programmable ignition? Anyone tried it? Seems the timing curve and rpm limits of a Harley engine would work on a stock xs650 engine...

For the cost of some of these you could use a microsquirt set up just to run ignition. It's the ECU I'm running for the EFI, so it's fully capable of running just ignition.

Use a 2" 36-1 trigger wheel inplace of the advance mechanism, allegro ats627 gear tooth sensor, you'd need to figure out a throttle position, and hook up a MAP sensor. Have it run a pair of chevy LS coils and it can run stock or rephase just by changing a setting.

They do a black friday sale, so that is the one time a year to get it cheaper. https://www.diyautotune.com/product/microsquirt-engine-management-system-w-30-wiring-harness/

Use a 2" 36-1 trigger wheel inplace of the advance mechanism, allegro ats627 gear tooth sensor, you'd need to figure out a throttle position, and hook up a MAP sensor. Have it run a pair of chevy LS coils and it can run stock or rephase just by changing a setting.

They do a black friday sale, so that is the one time a year to get it cheaper. https://www.diyautotune.com/product/microsquirt-engine-management-system-w-30-wiring-harness/

Ratranger, that is a very neat setup!

Is it really neccessary with the MAP sensor, or even a TPI, if just running it as an ignition controller? After all, the oem ignition is only rpm dependent. I do, however, see a potential benefit with a TPI input, as it may allow a bit more advanced timing in light load conditions.

Is it really neccessary with the MAP sensor, or even a TPI, if just running it as an ignition controller? After all, the oem ignition is only rpm dependent. I do, however, see a potential benefit with a TPI input, as it may allow a bit more advanced timing in light load conditions.

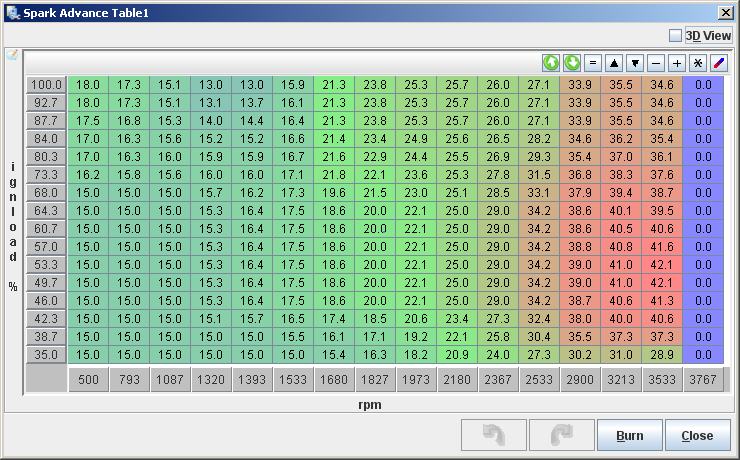

You really need either MAP or TPS, preferably both. The basic way the microsquirt works is you have the ignition table, bottom is RPM, side is load. Load can be MAP, or TPS or a combination. So the advance is based on load and RPM. Simplest is to start with TPS and RPM also known as AlphaN tuning. Then you can datalog and see what your vacuum signal looks like and incorporate it if you want.

Here's what a basic ignition table looks like.

Not mine, I've basically got the stock advance curve in mine, 13* at idle and 38.5* at max.

Here's what a basic ignition table looks like.

Not mine, I've basically got the stock advance curve in mine, 13* at idle and 38.5* at max.

I've been eyeing the Microsquirt ever since I followed your build Ratranger. To say I'm envious would be an understatement...You really need either MAP or TPS, preferably both. The basic way the microsquirt works is you have the ignition table, bottom is RPM, side is load. Load can be MAP, or TPS or a combination. So the advance is based on load and RPM. Simplest is to start with TPS and RPM also known as AlphaN tuning. Then you can datalog and see what your vacuum signal looks like and incorporate it if you want.

Here's what a basic ignition table looks like.

View attachment 149517

Not mine, I've basically got the stock advance curve in mine, 13* at idle and 38.5* at max.

They might be good enough for fuel only. For ignition you really want more accuracy. A majority of installs use either a factory trigger wheel or add a 36-1 wheel. That gives the ecu a pulse every 10* crank or 20* cam. 1 trigger every revolution is not good accuracy.

Actually the TCI has two triggers.... one for full retard and one for full advance. And that's what makes me think it will work.1 trigger every revolution is not good accuracy.

You might need to remove one magnet and have a single trigger. The manual shows that a dual trigger is normally on 4cyl wasted spark bikes. Probably 1 trigger for 1&4 and the second for 2&3. You couldn't do a rephase with a single trigger.

Rephase it would need a cam trigger like I have set up. Reason is the ecu needs to know where TDC for the compression stroke is on cylinder 1 in order to properly offset for the oddfire of the next.

Here's the manual page for anyone that wants to look through it. The hardware manual is the one with all the info http://www.msextra.com/manuals/ms2manuals/ . Also there is a forum on that page for any more specific questions.

Rephase it would need a cam trigger like I have set up. Reason is the ecu needs to know where TDC for the compression stroke is on cylinder 1 in order to properly offset for the oddfire of the next.

Here's the manual page for anyone that wants to look through it. The hardware manual is the one with all the info http://www.msextra.com/manuals/ms2manuals/ . Also there is a forum on that page for any more specific questions.

Similar threads

- Replies

- 22

- Views

- 855