Pete, if you don't own a strobe timing light and a multimeter, it's time to buy them. A few years back Yamaha produced a batch of new advance governors at a reasonable price, but thanks at least in part to ebay profiteers with the ethics of ticket scalpers, they didn't last long. Mike's XS offers a Chinese repop, and I strongly recommend avoiding it. To inspect your advance governor, all you need is a multitester set on the ohm meter function to tell you when the points open. With the ignition off and turning the motor by hand, check the full retard spark (points opening) first, then clip the weights to the tabs and check the full advance position. Don't bother looking for NOS weights alone; the weights were offered only as part of the whole assembly.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

REPETE'S XS650B Preservation Carburetor

- Thread starter REPETE

- Start date

REPETE

XS650 Addict

5t -

Very kind offer and appreciated.

When something goes awry (like losing the e-clip) I try to be as prepared as possible for the next time. So today I ordered a 300 pc set.

It’ll last me the rest of my life.

I will also shop around for a basic timing light tomorrow so I’ll be prepared.

Condenser showed up today.

Renting items aren’t expected till mid week,

I’ve thoroughly cleaned everything and am now in a hold pattern.

I’m trying to make sense of how this advance rod works.

I’ve watched the video where at higher rpm the weights fly open releasing the advance shaft. But at that point it appears to me that it’ll just be a free moving shaft passing through the cam. What makes it turn once the weights release?

I

Pete

Very kind offer and appreciated.

When something goes awry (like losing the e-clip) I try to be as prepared as possible for the next time. So today I ordered a 300 pc set.

It’ll last me the rest of my life.

I will also shop around for a basic timing light tomorrow so I’ll be prepared.

Condenser showed up today.

Renting items aren’t expected till mid week,

I’ve thoroughly cleaned everything and am now in a hold pattern.

I’m trying to make sense of how this advance rod works.

I’ve watched the video where at higher rpm the weights fly open releasing the advance shaft. But at that point it appears to me that it’ll just be a free moving shaft passing through the cam. What makes it turn once the weights release?

I

Pete

REPETE

XS650 Addict

grizld1 -

I have a multi meter and I go use it to zero in on when my points just begin to open. I learned on my enduros and applied the same technique to the XS (x2). I have that concept down.

I will be buying the timing light based on the strong recommendations. I’ll have a bit of a learning curve since it’s been 45yrs since I last used one.

Hopefully like riding a bicycle.

Pete

I have a multi meter and I go use it to zero in on when my points just begin to open. I learned on my enduros and applied the same technique to the XS (x2). I have that concept down.

I will be buying the timing light based on the strong recommendations. I’ll have a bit of a learning curve since it’s been 45yrs since I last used one.

Hopefully like riding a bicycle.

Pete

... the weights fly open releasing the advance shaft. But at that point it appears to me that it’ll just be a free moving shaft passing through the cam...

No, it doesn't release the advance shaft. The flyweight move outward, their ears nudge the disc about 13° in the advance direction, which translates to about 25° at the crank.

Right. When rpms increase, centrifugal force throws the bobweights against the tabs on the governor rotor, the tips of the weights turn the disk, the disk turns the rod, the rod turns the points cam, and the points open sooner.

Will just comment that many timing lights now have an advance degree knob, make sure it's at zero or....... timing light....... it’s been 45yrs........Pete

REPETE

XS650 Addict

Thanks Guys!

Well explained and demonstrated.

Picture is worth a thousand words, right?

I'm hoping I'm not the only one that had that misconception. I'm picking up some Moly Grease today but as I said, I'm in a hold pattern now waiting on parts.

I'm picking up some Moly Grease today but as I said, I'm in a hold pattern now waiting on parts.

I'm sure I can probably get a timing light at Harbor Freight so I'll get that done also.

It'll be an inactive XS weekend, but at least I'll feel as if I did something in the name of progress.

Pete

Well explained and demonstrated.

Picture is worth a thousand words, right?

I'm hoping I'm not the only one that had that misconception.

I'm picking up some Moly Grease today but as I said, I'm in a hold pattern now waiting on parts.

I'm picking up some Moly Grease today but as I said, I'm in a hold pattern now waiting on parts.I'm sure I can probably get a timing light at Harbor Freight so I'll get that done also.

It'll be an inactive XS weekend, but at least I'll feel as if I did something in the name of progress.

Pete

REPETE

XS650 Addict

Good Day to All!

I'm just checking in.

Varying orders are trickling in.

Last Saturday I got the NOS Capacitor. I have no way of knowing the level of performance of my original, but figured that I was replacing everything else so may as well replace that as well. For the most part, a clean sweep through the ignition components. Only remaining original piece is the coil.

I received the new (used) Advance Disc on Monday. It looks like new! I couldn't be happier. Sometimes I'll save used parts on the basis of "too good to throw out". But I'll be be tossing my original one. Compared to the new one it is very beat up. I can't see anybody wanting to use it short of desperation.

Yesterday I received one set of the NOS Points and the other set (based on USPS notifications) will be delivered today.

I purchased a timing light. To give you all an idea as to how long it's been since I used one, the last time I had one you needed to introduce a spring between the spark plug and the wire lead!!!

Also, I've spent some time reading links and posts and zeroed in on the amount of the lateral movement free play of the Advance Rod. Mine has .017".

So, I went ahead and ordered some shims that are scheduled to be delivered Friday.

I'm anxious to get this all buttoned back up and see if I can get it properly timed and what improvements it may have on my right carburetor not functioning at low rpm's... which is where this side excursion began.

If nothing else, I'll have a healthy and robust ignition system and will then know if my suspected carburetor issue is still an issue.

We shall soon see.

More to come.

Pete

I'm just checking in.

Varying orders are trickling in.

Last Saturday I got the NOS Capacitor. I have no way of knowing the level of performance of my original, but figured that I was replacing everything else so may as well replace that as well. For the most part, a clean sweep through the ignition components. Only remaining original piece is the coil.

I received the new (used) Advance Disc on Monday. It looks like new! I couldn't be happier. Sometimes I'll save used parts on the basis of "too good to throw out". But I'll be be tossing my original one. Compared to the new one it is very beat up. I can't see anybody wanting to use it short of desperation.

Yesterday I received one set of the NOS Points and the other set (based on USPS notifications) will be delivered today.

I purchased a timing light. To give you all an idea as to how long it's been since I used one, the last time I had one you needed to introduce a spring between the spark plug and the wire lead!!!

Also, I've spent some time reading links and posts and zeroed in on the amount of the lateral movement free play of the Advance Rod. Mine has .017".

So, I went ahead and ordered some shims that are scheduled to be delivered Friday.

I'm anxious to get this all buttoned back up and see if I can get it properly timed and what improvements it may have on my right carburetor not functioning at low rpm's... which is where this side excursion began.

If nothing else, I'll have a healthy and robust ignition system and will then know if my suspected carburetor issue is still an issue.

We shall soon see.

More to come.

Pete

Condensers are funny things. They can last a long, long time, or crap out any time. They are supposed to match a certain rating that is matched to the ignition system. If they do, they filter the current fed to the points and prevent the faces from pitting. Normal points wear with good condensers matched to the system has the points faces wearing evenly and developing a grainy or sandpaper-like texture on their faces. If the condenser is too far above or below the rating spec, the points faces pit. Unfortunately, due to manufacturing tolerances, even a new condenser can be off the spec. So, if the old condenser set is working well, giving normal points wear without excess face pitting, that means they're a good match to the system. Don't change them. Do get a spare set to keep on the shelf because as mentioned, the ones you are using could go belly up on you.

REPETE

XS650 Addict

Condensers are funny things........... Don't change them. Do get a spare set to keep on the shelf because as mentioned, the ones you are using could go belly up on you.

(again)

(again) I changed them last night.

The originals were cleaned and saved b/c I knew that they were working. So, they're here should I need to change back.

May as well find out if the "spare set" works now that they're in.

Pete

Oh, I'm sure they'll work, it's just that there's no guarantee they'll be perfectly matched to the system. Once you have the bike running, observe the points operating while the bike sits there idling. An occasional small spark around the points faces is normal but constant big sparking is bad. How do your old points faces look? Are they badly pitted? If yes, then a condenser change was probably a good idea.

Condensers can die of old age sitting on a temperature controlled warehouse shelf. Many "better" VOMs have a condenser (capacitor) checking function......

REPETE

XS650 Addict

.......How do your old points faces look? Are they badly pitted?.......

I can't say 5T.

Being that my initial goal was to just get the motor started when I got the bike one of the earliest things I did was file the points and set the gaps. I never really scrutinized them.

I had thought that once I got the motor started (or not) that I was going to put it aside while I finished up two restorations I was working on.... one being that little JT1 that I posted a picture of earlier and the other being a Hodaka Combat Wombat. Original goal was to complete those two by Thanksgiving. And then there was still one more bike waiting in the "restoration queue" before I'd start on the XS. I was figuring at best I'd begin working on it winter of 20/21.

Well, that didn't happen, did it?

As soon as I had success in getting the bike started I realized that my interest in "preserving" the bike was greater than I had initially thought and the prospect of riding it was becoming my focus.

And here we are.

As I addressed each and every item requiring attention (the bike had been sitting for 20+ yrs.) the project morphed like the proverbial onion... peel away one layer, and find two more.

But I am now in the final stages.

The bike runs great except for the right carburetor issue at low rpm's.

And with the wonderful guidance I've been receiving I know it'll get resolved.

I've kept a running list of every mechanical and electrical issue I've addressed and repaired or performed needed maintenance, and believe me, it's extensive.

When done, I'll post it. Might be useful to someone inexperienced as a guide to bringing a bike back to a point of road worthiness.

Pete

REPETE

XS650 Addict

Condensers can die of old age....

The replacement wasn't a lot of $$$ and based on this I'm glad I got it.

Pete

REPETE

XS650 Addict

A bit of progress tonight by applying (as best I could) the guidance & advice you all have been giving me concerning the ignition advance system.

I have it reassembled and am happy with the operation thus far.

Prior to installation a very thin coating of grease was applied the length of the rod.

The grooved bushings were filled with grease.

The rod has been shimmed (breaker cam side) to take free movement from .017” down to .003”.

Pins on rod facing same direction prior to installation of cam and advance disc.

New (used) advance disc installed.

Marker line on advance disc aligned +/- with corresponding reference line on mounting plate.

Weight pivot studs lubed with chain lubricant.

Ditto spring stud (just because).

Weight shims installed as removed - 2 on bottom, 1 on top.

Disk indents sparingly greased after weights in place by applying with dental tool to ensure complete coverage all the way to backside - but no sloppy excess.

Mechanical operation checked and I’m satisfied . Weights return completely to compressed position. I took a video to share but it won’t upload. But when they return there’s the sweet sound of the metal tap.

New points installed and wiring routed over top of springs.

Felt lubricating pads have been cleaned and softened and are currently absorbing some oil.

Tomorrow I will set the point gaps, set the timing and see if it starts.

I’m hoping the timing isn’t 180° out and I damage something..

If she starts, I’ll use the new timing light to dial in the timing as accurately as I can.

And then... fingers crossed.... I’ll check the right carburetor for operation at low rpm’s.

More to come and thanks for getting me to this point!

Pete

I have it reassembled and am happy with the operation thus far.

Prior to installation a very thin coating of grease was applied the length of the rod.

The grooved bushings were filled with grease.

The rod has been shimmed (breaker cam side) to take free movement from .017” down to .003”.

Pins on rod facing same direction prior to installation of cam and advance disc.

New (used) advance disc installed.

Marker line on advance disc aligned +/- with corresponding reference line on mounting plate.

Weight pivot studs lubed with chain lubricant.

Ditto spring stud (just because).

Weight shims installed as removed - 2 on bottom, 1 on top.

Disk indents sparingly greased after weights in place by applying with dental tool to ensure complete coverage all the way to backside - but no sloppy excess.

Mechanical operation checked and I’m satisfied . Weights return completely to compressed position. I took a video to share but it won’t upload. But when they return there’s the sweet sound of the metal tap.

New points installed and wiring routed over top of springs.

Felt lubricating pads have been cleaned and softened and are currently absorbing some oil.

Tomorrow I will set the point gaps, set the timing and see if it starts.

I’m hoping the timing isn’t 180° out and I damage something..

If she starts, I’ll use the new timing light to dial in the timing as accurately as I can.

And then... fingers crossed.... I’ll check the right carburetor for operation at low rpm’s.

More to come and thanks for getting me to this point!

Pete

Last edited:

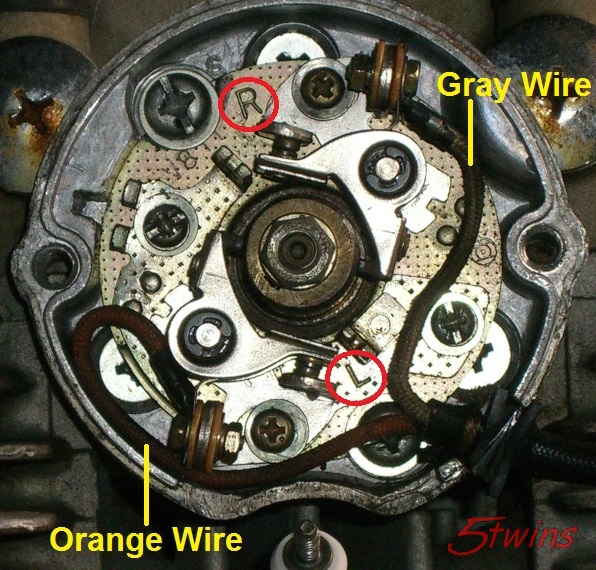

You'll find any excess lube you applied to the advance unit and it's parts flung off and all over the inside of the housing and it's cover if you check in there after running it for some miles. No big deal, just wipe it clean again. If you aligned everything as you say, the timing should be OK. You'll know right away when you go to static time it, if the it won't time up anywhere near the marks. Another thing that will throw the timing 180° off is having the points sets hooked up to the wrong coil and cylinder. They're marked on the plate, top set with an "R" (for right coil/cylinder) and bottom set with an "L" (for left coil/cylinder) .....

Wire colors were originally gray to the top (right) set and orange to the bottom (left) set.

Wire colors were originally gray to the top (right) set and orange to the bottom (left) set.

No fears, Pete. If the timing is 180* off at the cam it will be 360* off at the crank, and if that's the case you won't put the engine at risk; it won't start with spark delivered at approximate15* BTDC with pistons rising on the exhaust stroke. If you want to be sure everything is as it should be, remove the valve covers from one cylinder. Track the wires from the coil that fires that cylinder to its points set. With the ignition off, connect your ohm meter to that points set and turn the engine over slowly by hand until the points open. Now check the exposed rocker arms; there should be a bit of movement, indicating that both valves are closed.

Edit: Checking just the exhaust valve rocker will tell you what you need to know.

Edit: Checking just the exhaust valve rocker will tell you what you need to know.

Last edited:

REPETE

XS650 Addict

Thanks Fellas!

My confidence is at the other end of the spectrum from where it was before I disassembled the Advance.

I equated it to my experiences of pulling & resetting distributors back in the early 70's... I hated that!

Overall - and with the instruction/guidance y'all have provided not only was it not as big a deal as I had imagined, but I was able to make improvements along the way. A good overall feeling of accomplishment.

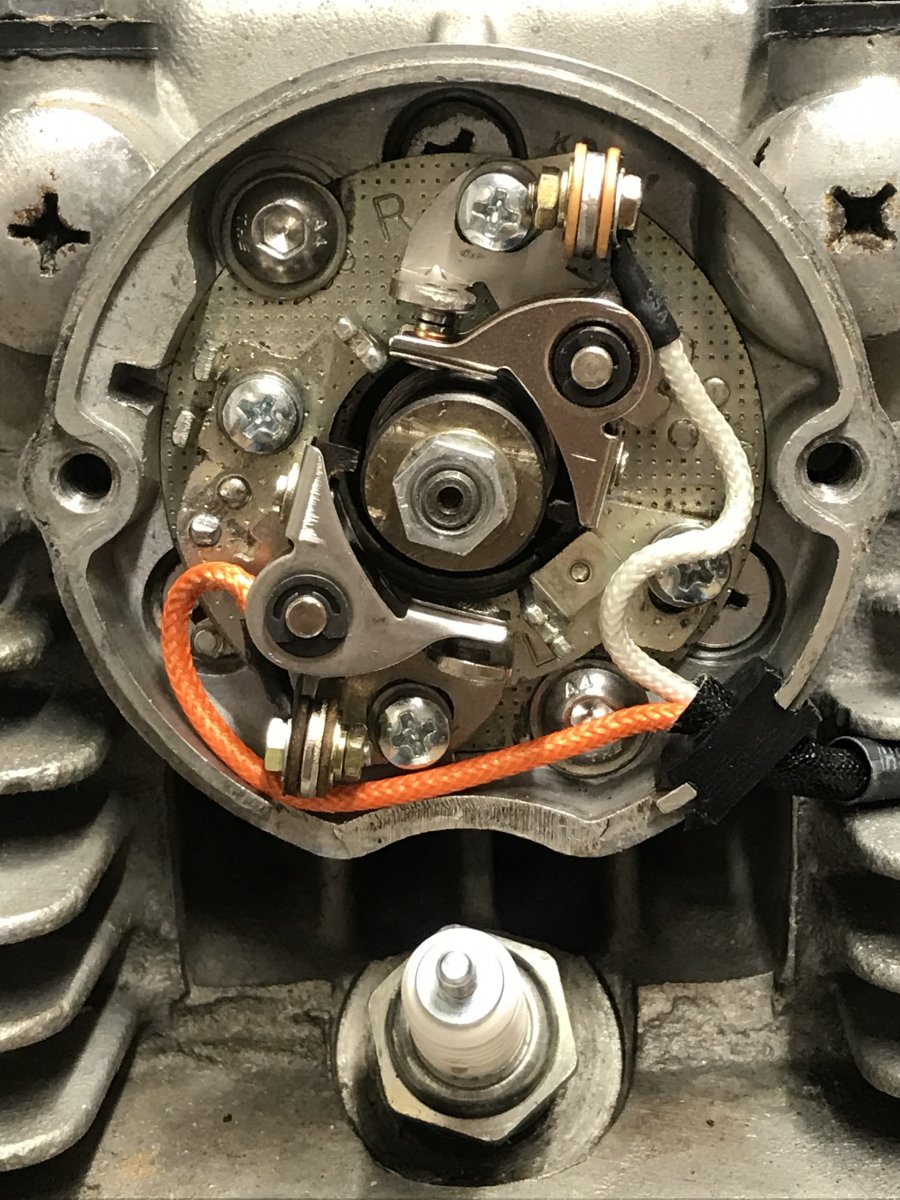

Here's my breaker plate cleanup & installation

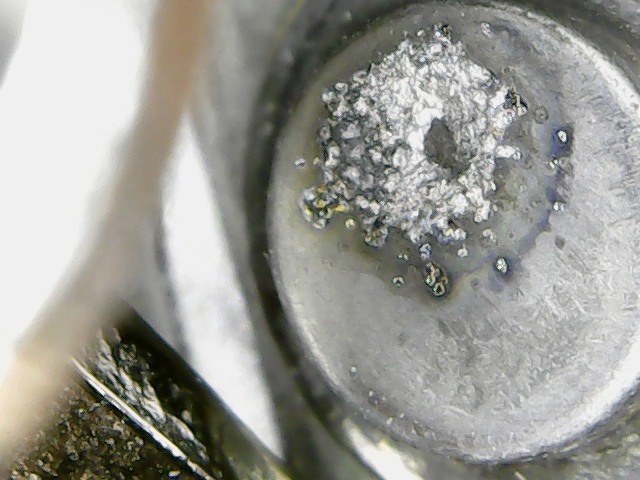

Also, 5T... you asked about the original points.

I brought them to work today and took these photos with my scope.

Not the best photo, but it gives you an idea of their condition.

Pete

My confidence is at the other end of the spectrum from where it was before I disassembled the Advance.

I equated it to my experiences of pulling & resetting distributors back in the early 70's... I hated that!

Overall - and with the instruction/guidance y'all have provided not only was it not as big a deal as I had imagined, but I was able to make improvements along the way. A good overall feeling of accomplishment.

Here's my breaker plate cleanup & installation

Also, 5T... you asked about the original points.

I brought them to work today and took these photos with my scope.

Not the best photo, but it gives you an idea of their condition.

Pete

...Here's my breaker plate cleanup & installation...

Yer missin' the felt wipers...

REPETE

XS650 Addict

Yer missin' the felt wipers...

They were soaking in cleaner and/or oil at the time the picture was taken

Similar threads

- Replies

- 31

- Views

- 859

- Replies

- 5

- Views

- 245

- Replies

- 22

- Views

- 470