Okey doke - well, Demi's new rear wheel is assembled and the truing went fairly well. It still has a bit of hop at one spot, but the axial (side-to-side) runout is minimal. I will fiddle around a bit more to get the radial hop a bit smaller - but I’m pretty happy. Thanks so much to everyone for the encouragement and especially to NightHog for the excellent photos of his wheel. They were the key to getting this ding-danged thing done as the photos I had taken of my wheel before I disassembled it were not clear enough to discern all the nuances. There are many videos online about lacing and truing wheels and so I won’t go into the details of that process, but here are the key points for doing one of these 48-spoke Heritage Special wheels:

However, you must not mix-up the four types of spokes (they are packed into marked groupings but there is no indication of which ones go where in the lacing pattern). I called MikesXS and XS650 Direct but they couldn’t offer me any help <surprise!>. All 48 nipples are the same (although in my experience, some nipples are MUCH more appealing than others...);

Don’t confuse the spoke pattern, the spoke direction and pattern offset with the sequence of spoke installation. As was pointed out to me earlier by (I think) 5Twins, the sequence is always to install all of the INNER spokes into the hub first and then connect them loosely to the rim with the nipples and then install all of the OUTER spokes and connect them. If you don’t do it this way, it will be impossible to thread all of the spokes into the hub - and you cannot bend them to get them in.

NOTE: If your spokes will not go in fairly easily and without forcing anything - you are doing it wrong. Stop and start again. Anyhow, as promised, here are some more photos:

INNER SPOKES INSTALLED

...and now, a photo with everything in-place and on the truing stand (thanks for the spare swing arm Lakeview!):

Like anything else, spoking a wheel and truing it is both easier than you might think and harder than it looks. There are several key tricks and tips but the most important is to be methodical and keep things organized. I have had all of the spokes in and out of this wheel at least 6 or 7 times - and each time I thought I had it right - but nope.

- and each time I thought I had it right - but nope.

Cheers,

Pete

- The kit from MikesXS / XS650Direct comes with 48 spokes

shootme

and nipples and a very nice 18” XSPerformance alloy rim to replace the 16” Special steel doughnut rim;

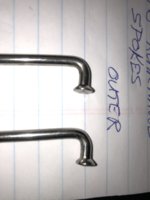

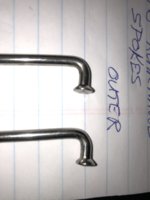

- The spoke kit has four (4) different types of spokes: short & long inner spokes and short & long outer spokes - and you can identify each type by the angle of the spoke head: the INNERS have a slightly larger than 90 deg. angle and the OUTERS have an angle of slightly less than 90 deg. since they have to angle-in toward the holes in the rim. If you look at the photos below, you’ll see what I mean.

- It is amazingly easy to mix them up - DAMHIK. I eventually got four Tupperware containers from the kitchen and labeled them - and I still messed them up a couple of times.

However, you must not mix-up the four types of spokes (they are packed into marked groupings but there is no indication of which ones go where in the lacing pattern). I called MikesXS and XS650 Direct but they couldn’t offer me any help <surprise!>. All 48 nipples are the same (although in my experience, some nipples are MUCH more appealing than others...);

- The real key, aside from identifying which spoke goes where in the pattern, is to start with the correct offset of the spoke pattern from one side of the hub to the other - and the best way to figure this out for the 48-spoke rear hub is to stare at NightHog’s photos (see below). Look carefully at the area near the tire valve and note that the spoke immediately adjacent to either side of the valve are SHORT-OUTERS.

Next to each short-outer will be a LONG-OUTER and then a SHORT-INNER and then a LONG-INNER etc. Note also the direction in which the spokes point relative to the direction of rotation. If you get all of that right, then the entire pattern on both sides of the wheel will work out properly.

Don’t confuse the spoke pattern, the spoke direction and pattern offset with the sequence of spoke installation. As was pointed out to me earlier by (I think) 5Twins, the sequence is always to install all of the INNER spokes into the hub first and then connect them loosely to the rim with the nipples and then install all of the OUTER spokes and connect them. If you don’t do it this way, it will be impossible to thread all of the spokes into the hub - and you cannot bend them to get them in.

NOTE: If your spokes will not go in fairly easily and without forcing anything - you are doing it wrong. Stop and start again. Anyhow, as promised, here are some more photos:

INNER SPOKES INSTALLED

...and now, a photo with everything in-place and on the truing stand (thanks for the spare swing arm Lakeview!):

Like anything else, spoking a wheel and truing it is both easier than you might think and harder than it looks. There are several key tricks and tips but the most important is to be methodical and keep things organized. I have had all of the spokes in and out of this wheel at least 6 or 7 times

- and each time I thought I had it right - but nope.

- and each time I thought I had it right - but nope.Cheers,

Pete

Last edited:

or I’ll be on the run like Gary and Ken).

or I’ll be on the run like Gary and Ken).