I just noticed a few rides ago that my right mirror would turn out of adjustment

I would tighten it a little adjust the mirror

and it would just loosen up again and again

and it would just loosen up again and again

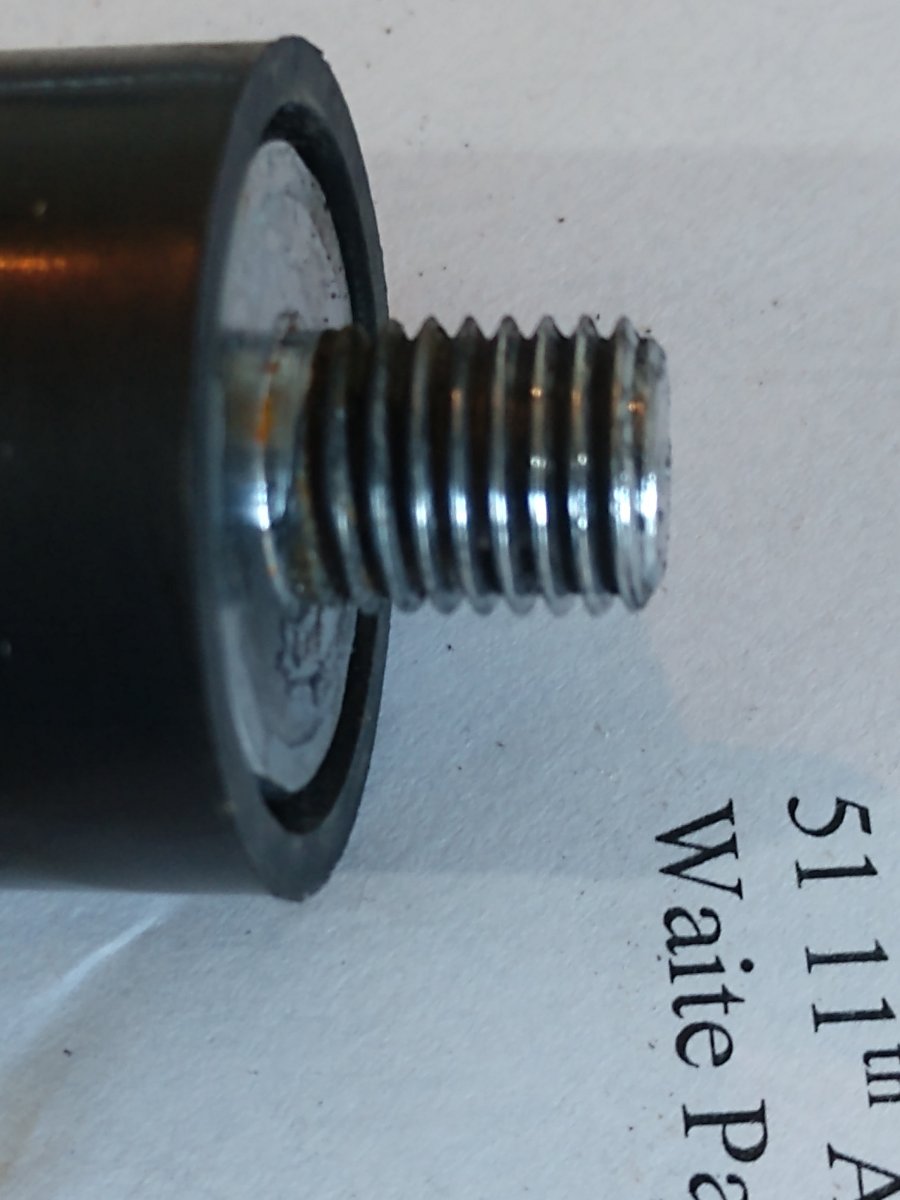

Anyway what could a person put on the threads to take the wobble out

Teflon tape / RTV ? just throwing it out there

I would tighten it a little adjust the mirror

Anyway what could a person put on the threads to take the wobble out

Teflon tape / RTV ? just throwing it out there

you previously didn't say that you had enough thread for a lock nut.. or a locknut lol..

you previously didn't say that you had enough thread for a lock nut.. or a locknut lol..