Following your work Bjorn! Would like to do an YZF600R fork/dual disk setup with spoke wheel at some time in the future.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Winter project: upgrading time! (R6 forks and more...)

Bjorn

XS650 Addict

Sounds cool Gary! I'll post as much details as possible. Might help other out

Regarding aluminium bearing spacers. They should work fine, I have made and fitted a few myself. I make them a tiny bit longer than stock, due to aluminium being more elastic than steel (Young's Modulus is only a third of steel, typically 70 GPa vs 210 GPa)

On my 1997 Ducati ST2, the OEM bearing spacers are super light alloy extrusions. Smooth inside, longitudinal ribs on the outside, for centering and stiffness. They appear to be made of a high tensile grade, most likely some 70XX. Definitely harder than 6082T6.

Regarding crankcase ventilation/ reed valve/ catch tank. After I fitted a reed valve from Heiden Tuning, and a single outlet oem breather to my internally stock 77 model, I haven't seen a single drop of oil escaping from the breather hose. I just have it pointing downwards between the carbs, so any oil should show immedeately on top of the crankcase/gearbox. Your reed valve seems to be of a newer design, integrated into the breather housing, while mine is attached to an oem breather via a short hose. Bottom of the line is that you most likely never need to drain your catch tank.

Although dual discs look great, the front suspension definitely works better with a single And my take on oem vs aftermarket electronic speedo is definitely in favor of aftermarket. Less weight, both unsprung and sprung. No cable to worry about, more exact/correct. And generally added functions like max/average/ dual trip meters and so on. I have good experience with Koso and Daytona

On my 1997 Ducati ST2, the OEM bearing spacers are super light alloy extrusions. Smooth inside, longitudinal ribs on the outside, for centering and stiffness. They appear to be made of a high tensile grade, most likely some 70XX. Definitely harder than 6082T6.

Regarding crankcase ventilation/ reed valve/ catch tank. After I fitted a reed valve from Heiden Tuning, and a single outlet oem breather to my internally stock 77 model, I haven't seen a single drop of oil escaping from the breather hose. I just have it pointing downwards between the carbs, so any oil should show immedeately on top of the crankcase/gearbox. Your reed valve seems to be of a newer design, integrated into the breather housing, while mine is attached to an oem breather via a short hose. Bottom of the line is that you most likely never need to drain your catch tank.

Although dual discs look great, the front suspension definitely works better with a single And my take on oem vs aftermarket electronic speedo is definitely in favor of aftermarket. Less weight, both unsprung and sprung. No cable to worry about, more exact/correct. And generally added functions like max/average/ dual trip meters and so on. I have good experience with Koso and Daytona

Last edited:

Bjorn

XS650 Addict

Great feedback, thanks!

Good to know alu works a bearing spacer . I think I used 6000 series. At work we use a lot of 7075 and 2024, both are quite strong.

Interesting your breather didn't show any drips. My filter on the end was still sweating a bit. That's why I made the catch tank. We'll see if it stays dry. If it does, made a great practice welding thin stuff haha.

Yeah I can't argue that the aftermarket Speedo does have its benefits. I'm just not super convinced it can handle the XS vibrations....

I worked in automotive doing vibrations tests on components, I know for a fact it can mess up quite a lot. I do know the OEM Speedo works...

Why would the setup work better with one disc? It's a fork that came originally with double discs... interesting to hear your view on it.

Also scored some nice second hand parts:

Good to know alu works a bearing spacer . I think I used 6000 series. At work we use a lot of 7075 and 2024, both are quite strong.

Interesting your breather didn't show any drips. My filter on the end was still sweating a bit. That's why I made the catch tank. We'll see if it stays dry. If it does, made a great practice welding thin stuff haha.

Yeah I can't argue that the aftermarket Speedo does have its benefits. I'm just not super convinced it can handle the XS vibrations....

I worked in automotive doing vibrations tests on components, I know for a fact it can mess up quite a lot. I do know the OEM Speedo works...

Why would the setup work better with one disc? It's a fork that came originally with double discs... interesting to hear your view on it.

Also scored some nice second hand parts:

LEGEND_10

XS650 Enthusiast

Bjorn, sorry for the late response. I have about .230" clearance.@LEGEND_10 how much clearance does this give you between the spokes and callipers?

Bjorn

XS650 Addict

After taking my XS for a trip I realized I never posted any updates here about the forks and stuff. Let me see if i can find some pictures of the parts ive been making in the last couple of months.

Bjorn

XS650 Addict

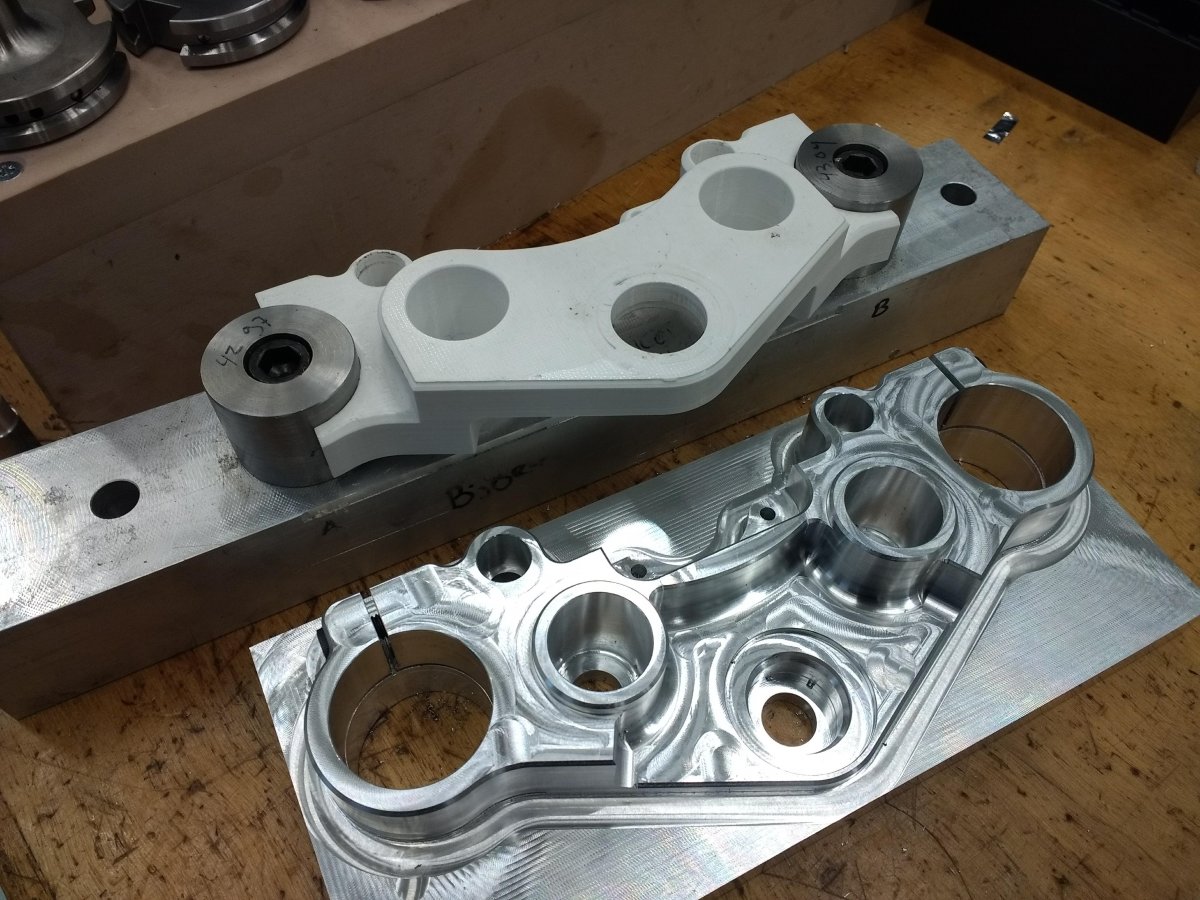

As a beginning machinist I really enjoyed making this top yoke, learned lots!

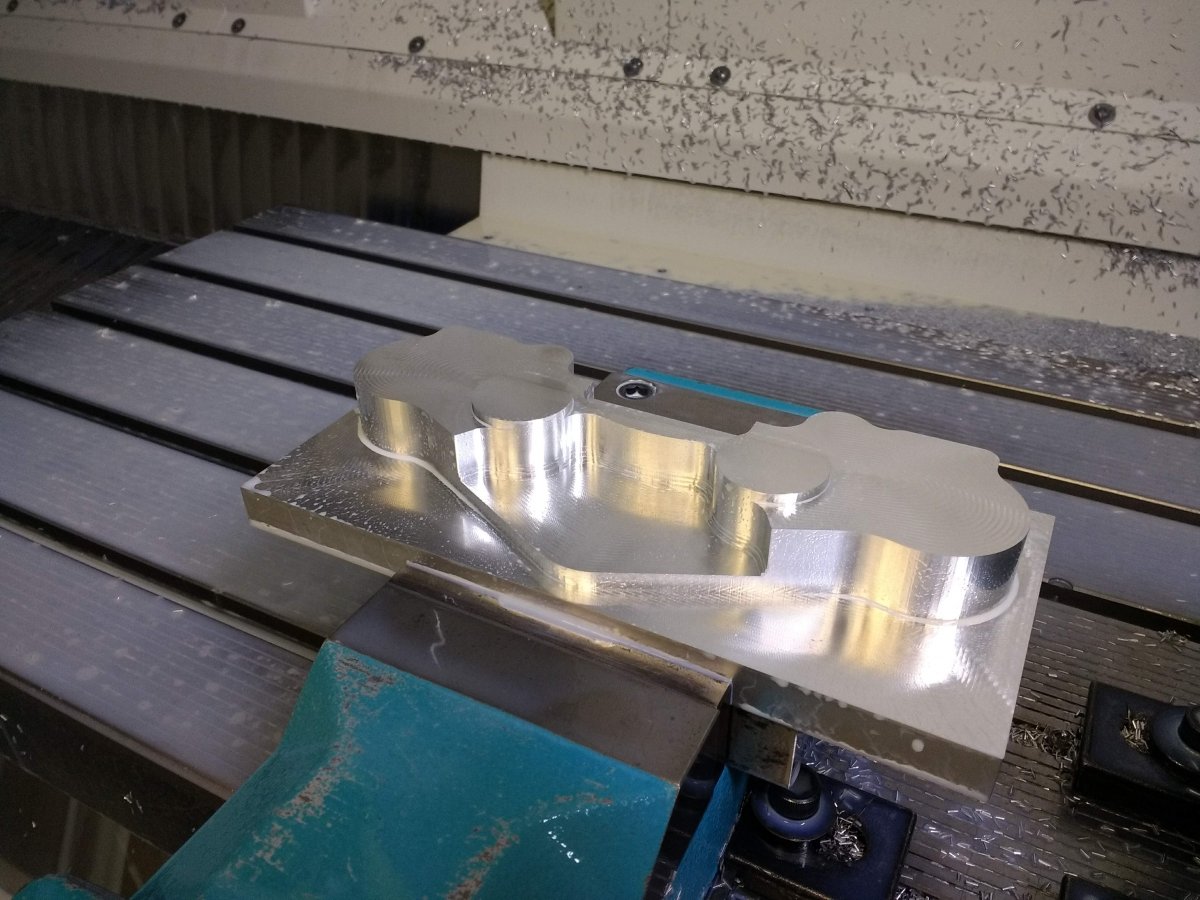

It started out life as a block of 5083 aluminium. Not as strong as 7075 but the mechanical properties are about the same as 6082. It is very corrosion resistant.

I started with the bottom, here the roughing has been done.

I started with the bottom, here the roughing has been done.

Holes added and some more finishing work.

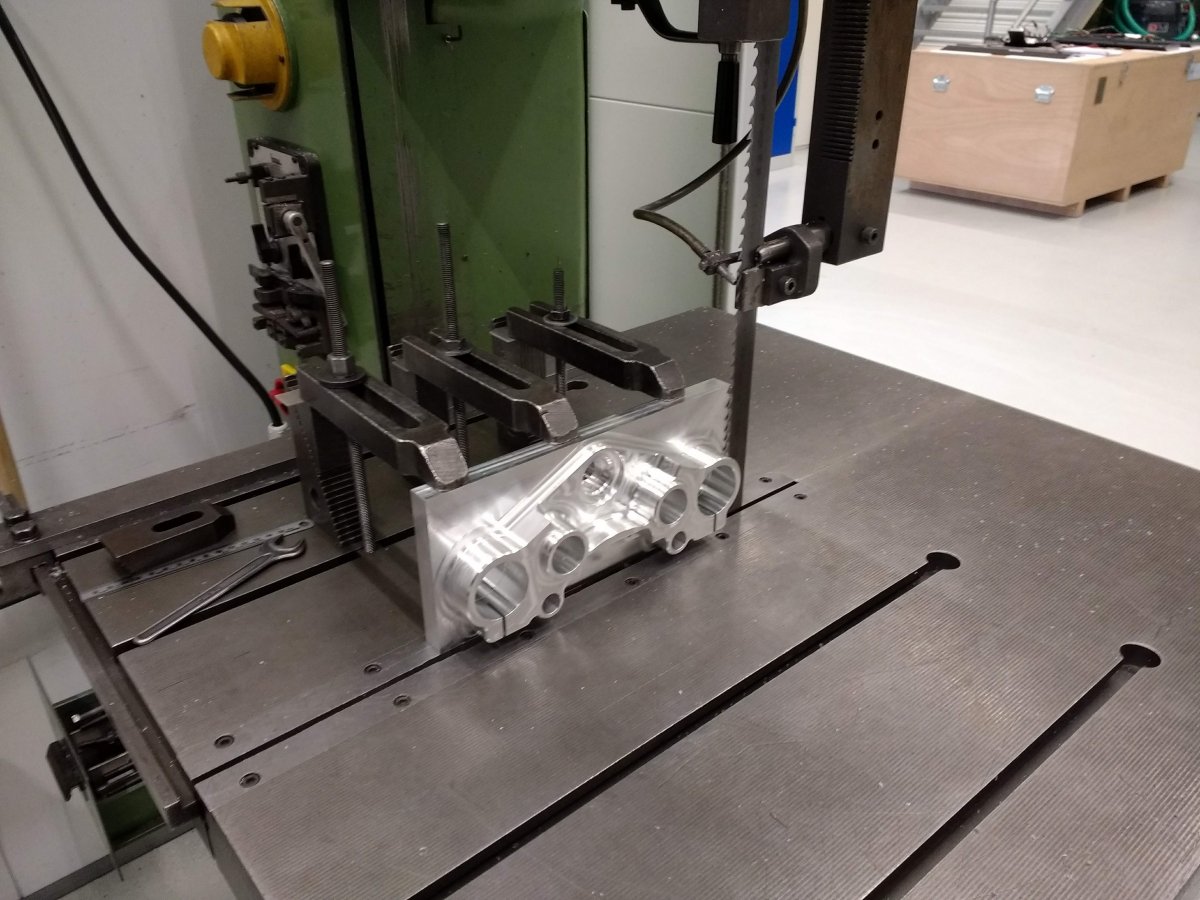

In order to do set-up 2 on the machine, I needed to make a cut in the yoke so I can use its clamping mechanism.

I made a jig representing the forks of the bike. That way i can clamp the yoke and machine everything around it.

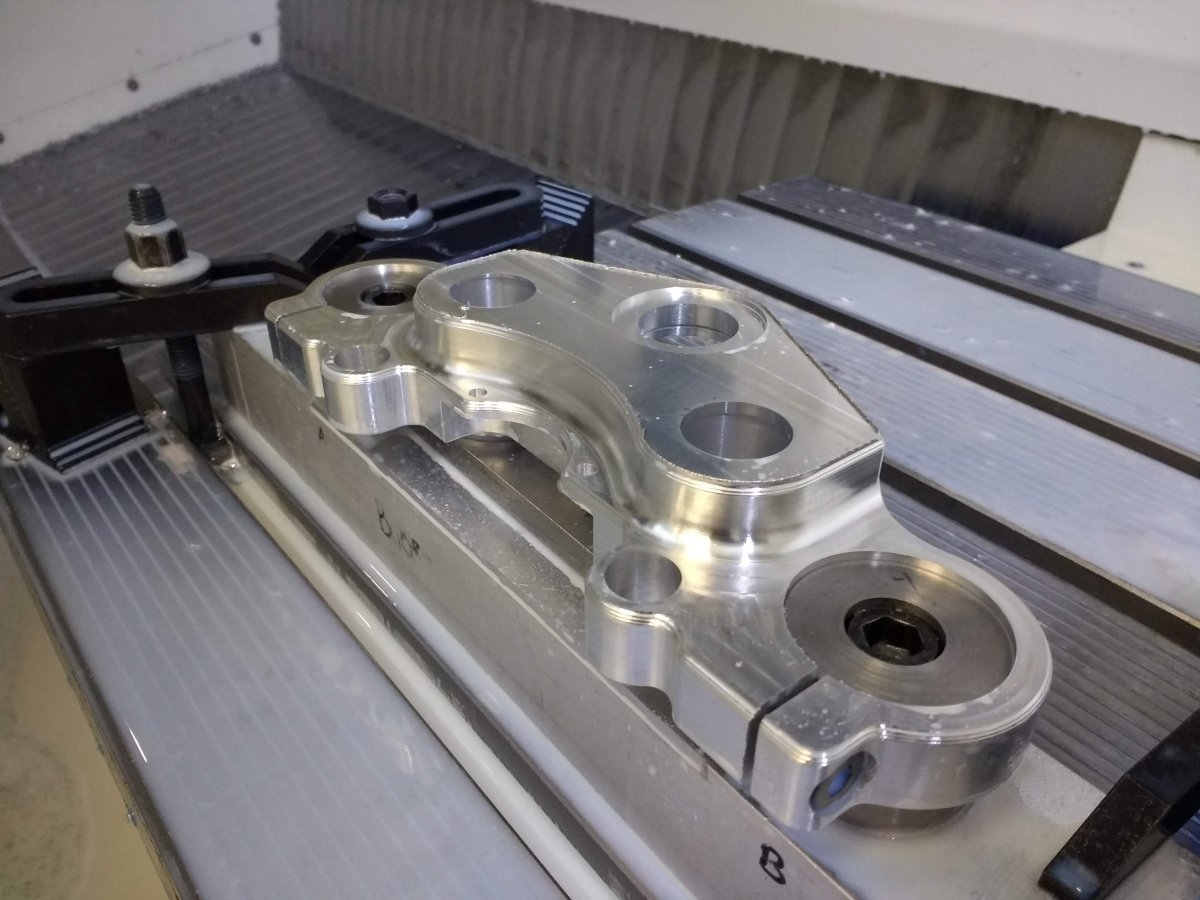

Second set-up on the machine. making sure its level with the machine axis.

Here most of the top side is machined, leaving only the top fillets to be done with a ballnose endmill

Here most of the top side is machined, leaving only the top fillets to be done with a ballnose endmill

here is the end result, super happy how it cam out!

last step was to press in the vibration dampers for the handlebars.

Gonna leave the yoke like it is now. I might have it anodized this winter, not sure yet.

It started out life as a block of 5083 aluminium. Not as strong as 7075 but the mechanical properties are about the same as 6082. It is very corrosion resistant.

Holes added and some more finishing work.

In order to do set-up 2 on the machine, I needed to make a cut in the yoke so I can use its clamping mechanism.

I made a jig representing the forks of the bike. That way i can clamp the yoke and machine everything around it.

Second set-up on the machine. making sure its level with the machine axis.

here is the end result, super happy how it cam out!

last step was to press in the vibration dampers for the handlebars.

Gonna leave the yoke like it is now. I might have it anodized this winter, not sure yet.

Bjorn

XS650 Addict

Here it is mounted on the bike

Couldn't stand the molested stem nut. The PO removed the dome from the nut in order to install a RAM mount.

Couldn't stand the molested stem nut. The PO removed the dome from the nut in order to install a RAM mount.

Made a new nut

Much better! For now I used to handlebar risers I had. But i want to make new ones. these are super heavy, I think I can make a version that is more lightweight.

Much better! For now I used to handlebar risers I had. But i want to make new ones. these are super heavy, I think I can make a version that is more lightweight.

The R6 master cylinder uses a separate fluid container, or morning urine pot as I like to call it. I didnt have a bracket.....Because...CNC haha.

Dont be fooled by the amount of work that goes into making a bracket like this. Yes the end result might look simple but first you got to come up with the design, then draw it in CAD and finally do the CAM programming to actually have the machine make it. Single pieces might actually take more time this way.

The R6 forks have a different diameter than the original XS ones. I made some brackets to be able to mount the headlight. Here there is a benefit doing it on a CNC. the first takes the most time. the rest is a matter of hitting cycle start

The R6 forks have a different diameter than the original XS ones. I made some brackets to be able to mount the headlight. Here there is a benefit doing it on a CNC. the first takes the most time. the rest is a matter of hitting cycle start

Made a new nut

The R6 master cylinder uses a separate fluid container, or morning urine pot as I like to call it. I didnt have a bracket.....Because...CNC haha.

Dont be fooled by the amount of work that goes into making a bracket like this. Yes the end result might look simple but first you got to come up with the design, then draw it in CAD and finally do the CAM programming to actually have the machine make it. Single pieces might actually take more time this way.

Bjorn

XS650 Addict

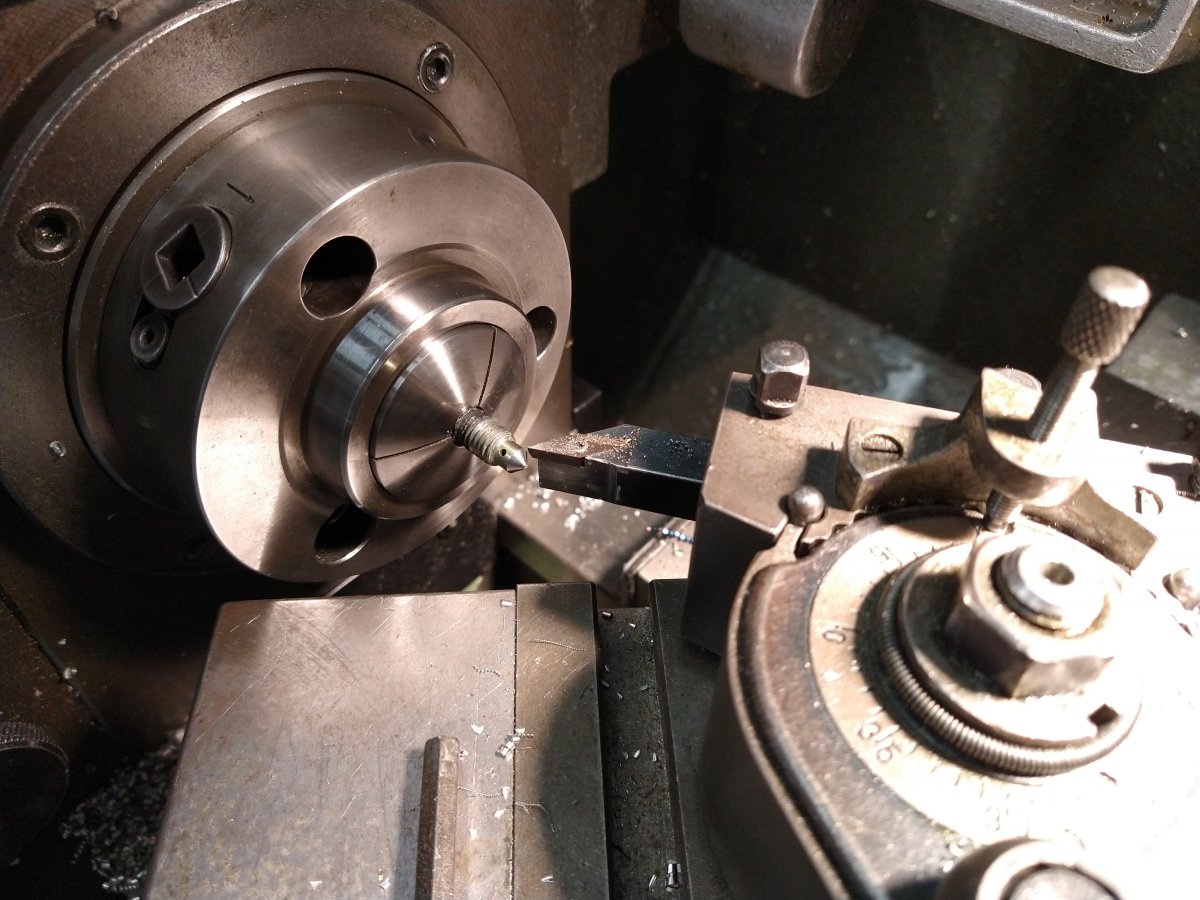

I bought a adjustable clutch lever from a KTM, sure enough the adjuster bolt didn't fit, it uses a fine metric pitch. Had to make one myself

Remember these wheel - brakedisk spacers? I made them at home but figured i could remove some excess weight to keep the unsprung weight down.

Also made a new spacer for the replacement of the speedo pick up. Wont be using that anymore.

Here is the wheel assembly with the spacers and TDM 850 disks.

Remember these wheel - brakedisk spacers? I made them at home but figured i could remove some excess weight to keep the unsprung weight down.

Also made a new spacer for the replacement of the speedo pick up. Wont be using that anymore.

Here is the wheel assembly with the spacers and TDM 850 disks.

Last edited:

Bjorn

XS650 Addict

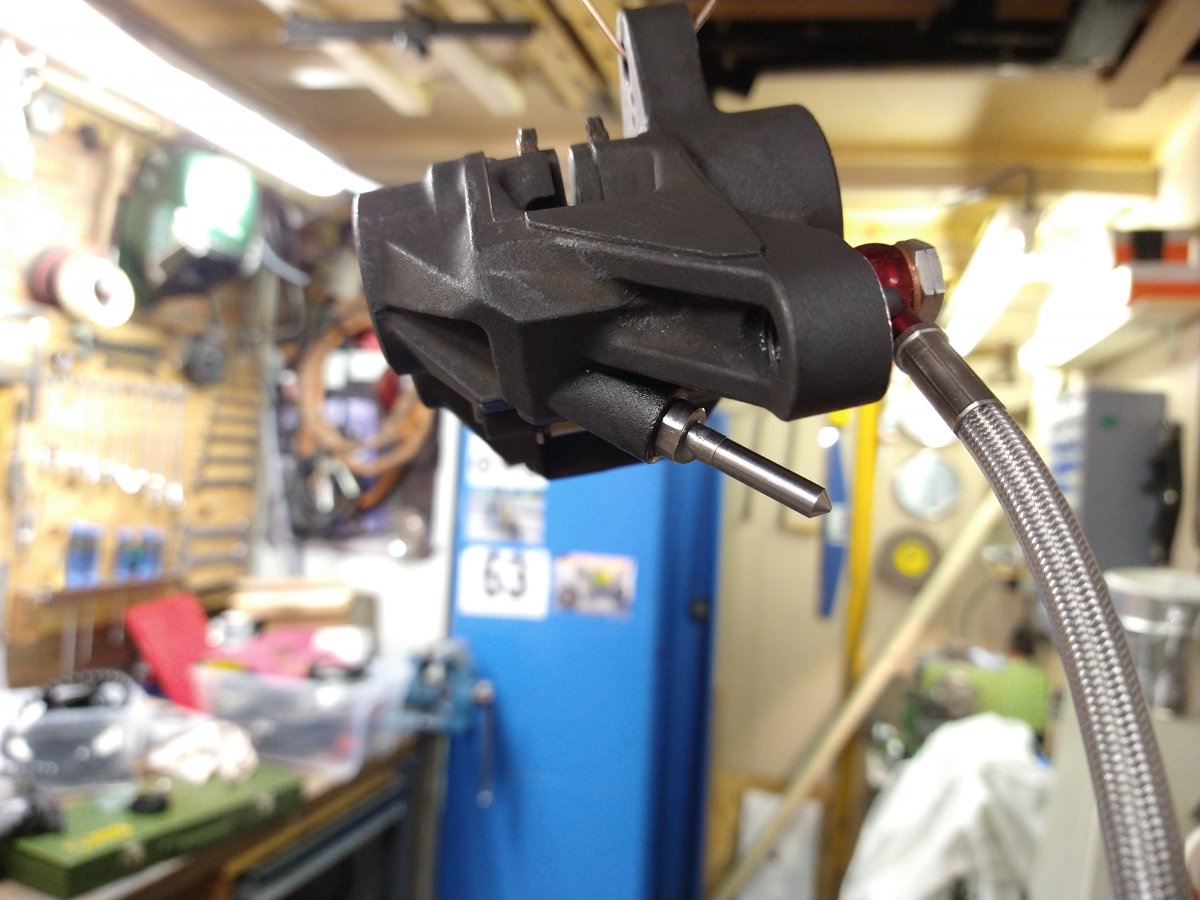

I had some bad luck with the brake set-up at first. They came with the forks and looked decent on the outside. After fitting the entire system together, it took me about one day of cursing to get all the air out of the system. The next day i would see the bleed nipples weeping  They were holding pressure but i couldn't live with this. I tried the easy stuff first. The nipples themselves use a 90° seat against the brake calliper. since they looked beat up, i refreshed them first.

They were holding pressure but i couldn't live with this. I tried the easy stuff first. The nipples themselves use a 90° seat against the brake calliper. since they looked beat up, i refreshed them first.

I cut a new 90° face on the nipple to see if it would cure the problem. Unfortunately it didn't.

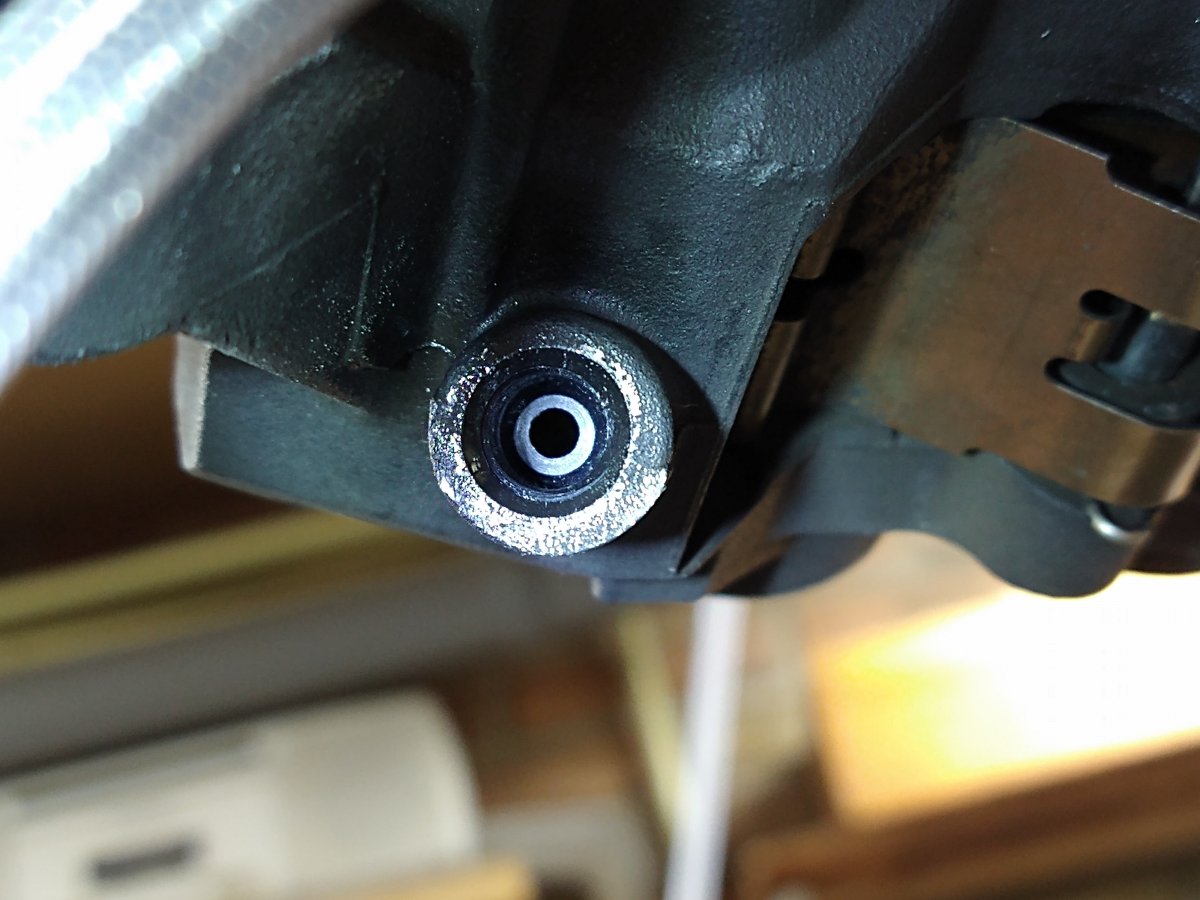

Inspecting the seats of the callipers is hard because they are hidden deep inside the calliper body. I made a lap and a guiding bushing to re-lap the seats. Just like you would with the seats of valves.

Here is the lap

Here is the lap

Really didnt want to bleed the system again, so i mounted the callipers upside-down for this step. Used the grinding paste for valves, course and fine. Afterwards i flushed out the entire system with clean fluid.

Really didnt want to bleed the system again, so i mounted the callipers upside-down for this step. Used the grinding paste for valves, course and fine. Afterwards i flushed out the entire system with clean fluid.

After this i had no more leaks

I cut a new 90° face on the nipple to see if it would cure the problem. Unfortunately it didn't.

Inspecting the seats of the callipers is hard because they are hidden deep inside the calliper body. I made a lap and a guiding bushing to re-lap the seats. Just like you would with the seats of valves.

After this i had no more leaks

Bjorn

XS650 Addict

probably skipped over some details along the way. But here is the end result:

And i made this quick little video:

I took the bike for a long weekend to Luxemburg with some friends. unfortunately I had (and still have) some nasty malfunctions with the ignition system which made it more of an adventure then i wanted. Any ways you can read more about that in my other topic (Help safe my trip).

On the positive side: The forks and brakes work outstanding! I could not be more pleased with the end result. I think my offset top yoke paid off because the bike doesn't feel nervous at all. The brakes are unbelievable. two finger braking all day long. my friends ride mainly old BMW's (R60,R80 and R100). Riding those bikes, made me realize how much better the forks and brakes are.

Apart from the non running issues, there are still some things I want to look into. Things like a lightweight front fender, been using the oem steel one for now. getting the tacho to work, changing the seat, it looks comfy but isnt. and probably lots more.

Let me know what you guys think! and if you have any questions, shoot!

And i made this quick little video:

I took the bike for a long weekend to Luxemburg with some friends. unfortunately I had (and still have) some nasty malfunctions with the ignition system which made it more of an adventure then i wanted. Any ways you can read more about that in my other topic (Help safe my trip).

On the positive side: The forks and brakes work outstanding! I could not be more pleased with the end result. I think my offset top yoke paid off because the bike doesn't feel nervous at all. The brakes are unbelievable. two finger braking all day long. my friends ride mainly old BMW's (R60,R80 and R100). Riding those bikes, made me realize how much better the forks and brakes are.

Apart from the non running issues, there are still some things I want to look into. Things like a lightweight front fender, been using the oem steel one for now. getting the tacho to work, changing the seat, it looks comfy but isnt. and probably lots more.

Let me know what you guys think! and if you have any questions, shoot!

Wow, just WOW!

Thanks for the detailed report on the front end. Hung on every word of your machining, CAD adventure.

You know you just forced me to do an R6 front with spoke wheel? Thanks bbbbBuddy!

Thanks for the detailed report on the front end. Hung on every word of your machining, CAD adventure.

You know you just forced me to do an R6 front with spoke wheel? Thanks bbbbBuddy!

Bjorn

XS650 Addict

so after one whole trip this year, the bike is back in the shed for never-ending modifications. I want to improve the bike in its daily usability so I can use it more next year. The overall idea is an XS Restomod for daily use. Things on the list are:

Better ergonomics (peg position and seat)

Better electronics (to make for a riding season instead of wrenching haha )

)

Remove as much weight as i can without sacrificing usability

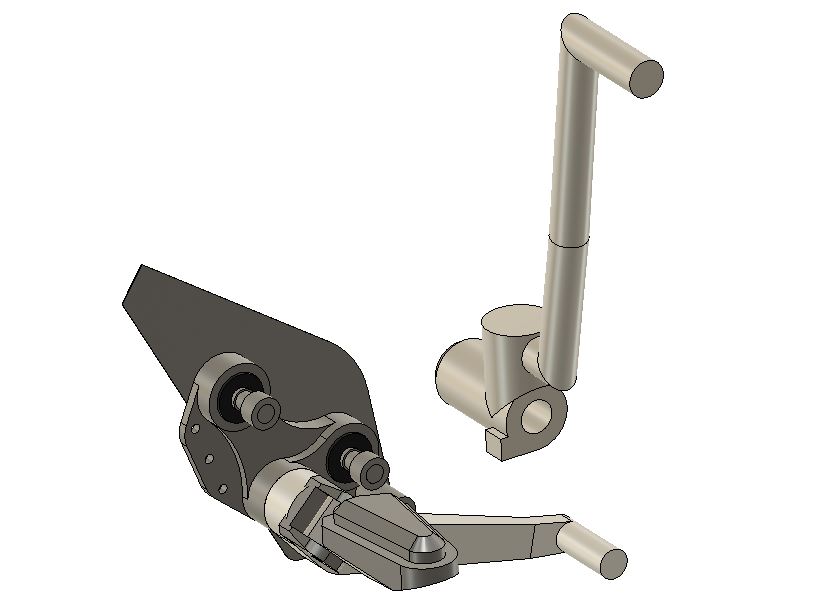

Im now working on the rearsets or midsets as i prefer to call them. I never liked the original peg position. Too far forward which makes for an inactive way of sitting on the bike. My back start to hurt sooner than on my modern MT07. So the plan is to move the pegs to a more central position. The challenge here is that i only got a kickstarter and dont plan on reinstalling an E-start. Its too heavy an requires a whole bunch of stuff I dont want. I moved from the shed to the computer in order to improve my CAD game. Its a nice project to learn.

Clearance is tight but after many iterations, the design is moving in the right direction.

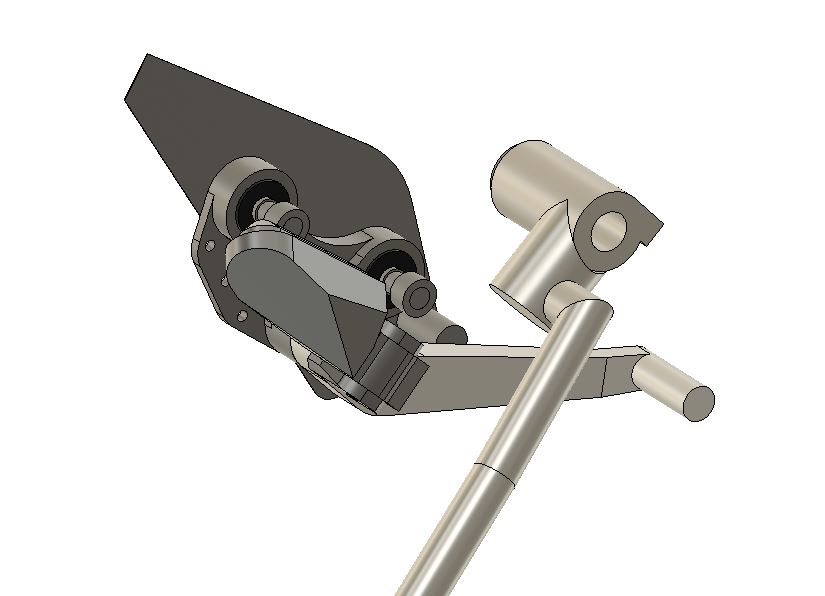

Measuring all the parts on the bike took quite some time, however it does make designing easier. Here is the current version.

With everything folded in, the kickstarter should clear.

This was the first adapter, however after testing, i found the peg to be a bit too far backward.

Here is version two with a adapter for the peg that will also be the bearing for the brake pedal

i wanted the pegs to be foldable without the risk of the kickstarter (or my leg) hitting them when trying to start the bike.

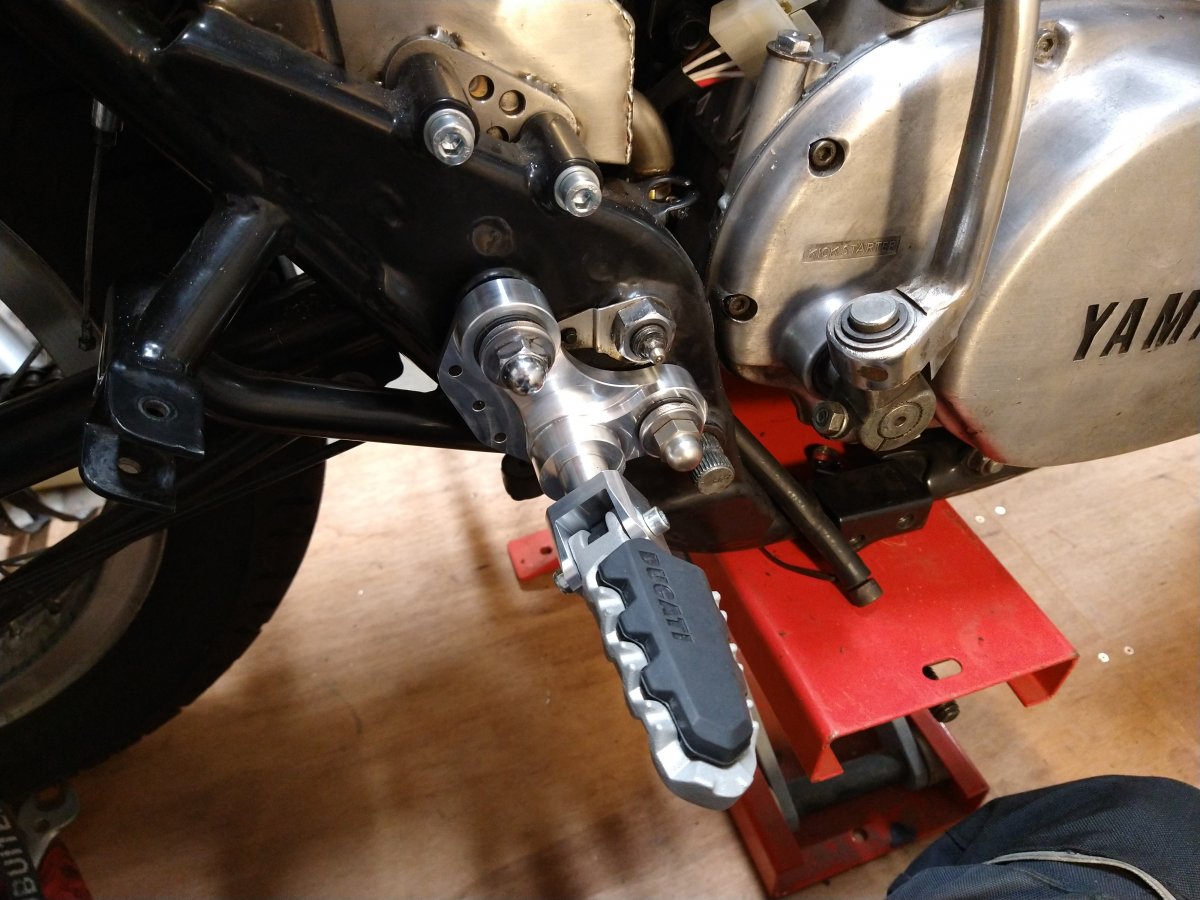

Here is the sub assembly. Thanks to ArticXS for paving the way with the Ducati rubbers. They seem to work perfect. Also went with the Ducati pegs instead of the KTM ones i posted earlier. They turned out to be forged steel and incredibly heavy with 350 grams each. These being only a 1/3 with the rubber. To provide some extra vibrations damping.

with 350 grams each. These being only a 1/3 with the rubber. To provide some extra vibrations damping.

\

And on the bike.

I found the folding-sound tooo satisfying not to make a video :

:

Next step i to work out the brake pedal and lever system. Im keeping the drum brake for now, but plan on making a new swingarm/hub with brake disk in the future. So i prepared the midsets with mounting points for the brake cylinder

Better ergonomics (peg position and seat)

Better electronics (to make for a riding season instead of wrenching haha

Remove as much weight as i can without sacrificing usability

Im now working on the rearsets or midsets as i prefer to call them. I never liked the original peg position. Too far forward which makes for an inactive way of sitting on the bike. My back start to hurt sooner than on my modern MT07. So the plan is to move the pegs to a more central position. The challenge here is that i only got a kickstarter and dont plan on reinstalling an E-start. Its too heavy an requires a whole bunch of stuff I dont want. I moved from the shed to the computer in order to improve my CAD game. Its a nice project to learn.

Clearance is tight but after many iterations, the design is moving in the right direction.

Measuring all the parts on the bike took quite some time, however it does make designing easier. Here is the current version.

With everything folded in, the kickstarter should clear.

This was the first adapter, however after testing, i found the peg to be a bit too far backward.

Here is version two with a adapter for the peg that will also be the bearing for the brake pedal

i wanted the pegs to be foldable without the risk of the kickstarter (or my leg) hitting them when trying to start the bike.

Here is the sub assembly. Thanks to ArticXS for paving the way with the Ducati rubbers. They seem to work perfect. Also went with the Ducati pegs instead of the KTM ones i posted earlier. They turned out to be forged steel and incredibly heavy

with 350 grams each. These being only a 1/3 with the rubber. To provide some extra vibrations damping.

with 350 grams each. These being only a 1/3 with the rubber. To provide some extra vibrations damping.\

And on the bike.

I found the folding-sound tooo satisfying not to make a video

:

:Next step i to work out the brake pedal and lever system. Im keeping the drum brake for now, but plan on making a new swingarm/hub with brake disk in the future. So i prepared the midsets with mounting points for the brake cylinder

Fantastic work! Good that the Ducati rubber bushings worked for you.

Have you considered making more footpeg sets? I am sure there are a few that would want them. Myself included

Other rearsets, like LSL are too far back IMHO.

Have you considered making more footpeg sets? I am sure there are a few that would want them. Myself included

Other rearsets, like LSL are too far back IMHO.

Btw, is that peg adapter SS or aluminium?

I just sit here and drool on those CNC beauties!

Bjorn

XS650 Addict

Fantastic work! Good that the Ducati rubber bushings worked for you.

Have you considered making more footpeg sets? I am sure there are a few that would want them. Myself included

Other rearsets, like LSL are too far back IMHO.

Thanks!

Before I make more I want to fully build and test everything on my bike. But if people are interested in a set I would love to hear from you!

All the parts so far are from 7075 aluminium

Thanks!

Before I make more I want to fully build and test everything on my bike. But if people are interested in a set I would love to hear from you!

All the parts so far are from 7075 aluminium

I love everything that you’ve done so far Bjorn and I’m sure, like many others on here are, drooling over your work!

I’d be interested in talking to you about foot pegs!

Daniel.

Id be interested in hearing rough numbers for 2 top triples!

Similar threads

- Replies

- 6

- Views

- 2K