The job isn't over till the paperwork is done.

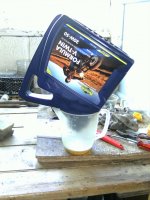

View attachment 197287 View attachment 197288

I guess it's pretty sad, but with three bikes to look after, I always print off, complete and file a check list for every service. And before anybody asks, yes, checked the electrics - just took the photo before I'd made the tick.

***** Digression warning *****

When I sold a Victory Hammer through a dealership - there aren't many or any buyers for sommat like that in the Scottish Borders so I took the bike to a dealer in a large English city on a commission basis - he asked if I had a full service record. But when I showed him, he said

'That's not a service record. Without a dealer's stamp, how can anybody be sure the work has been done. You could have made those up last night.' So we had a chat. Eventually he agreed to sell the bike as having an

owner's service record. I believe the man who bought the bike was more than happy that the bike had been serviced by a careful owner.