Thats actually how I've taught guys how to TIG in the past is to start with with silicon bronze filler at a lower amperage in order to get the motions down and get used to holding the torch and feeding filler.Oh yeah it should hold.. i think. I usually use silicon bronze over a tig bead to just get the appearance

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mannulus Mechanica (build thread)

- Thread starter RustiePyles

- Start date

-

- Tags

- bobber

TJZ662

XS650 Addict

That’s interesting, I can definitely see the benefits of everything being slowed down. I learned on aluminum coming from a stick only background, so I had to learn to feed filler very quickly. Definitely the trickiest part for me.

That’s interesting, I can definitely see the benefits of everything being slowed down. I learned on aluminum coming from a stick only background, so I had to learn to feed filler very quickly. Definitely the trickiest part for me.

TJZ662

XS650 Addict

Ohh yeah you’ll be burning your glove off if you’re not feeding fast enough

Rear light ideas

If not the Cadillac cone is suitable you in the US have a lot of other very nice styled Car rearlights

from the 50 ies into the early mid eighties We cant go to a salvage here find those

Fex 63 Chevy or there about should be small enough . And there are large ones

more striking

I have always liked the Ford Galaxie rear round but it is to large here

Plymoth cuda 72 73 74 has round ones.

One could on some build have a running light standing turned 90 degrees.

Some holder a man like you can manufacture that would look strikingly pretty.

OK it is a matter of style and taste ..

If not the Cadillac cone is suitable you in the US have a lot of other very nice styled Car rearlights

from the 50 ies into the early mid eighties We cant go to a salvage here find those

Fex 63 Chevy or there about should be small enough . And there are large ones

more striking

I have always liked the Ford Galaxie rear round but it is to large here

Plymoth cuda 72 73 74 has round ones.

One could on some build have a running light standing turned 90 degrees.

Some holder a man like you can manufacture that would look strikingly pretty.

OK it is a matter of style and taste ..

I ended up with a Bates (LED) light mounted on a skeletonized aluminum Maund Speed plate mount.Rear light ideas

If not the Cadillac cone is suitable you in the US have a lot of other very nice styled Car rearlights

from the 50 ies into the early mid eighties We cant go to a salvage here find those

Fex 63 Chevy or there about should be small enough . And there are large ones

more striking

I have always liked the Ford Galaxie rear round but it is to large here

Plymoth cuda 72 73 74 has round ones.

One could on some build have a running light standing turned 90 degrees.

Some holder a man like you can manufacture that would look strikingly pretty.

OK it is a matter of style and taste ..

Finished drilling my rotor.

Started tearing my front caliper down.

I'd add more holes. If the holes don't cover the entire swept area of the disk, you could see uneven pad wear.

'sides.... makes it lighter.

'sides.... makes it lighter.

Seeing it done, I kinda thought the same thing. I think I may chuck it up and add some more holes.I'd add more holes. If the holes don't cover the entire swept area of the disk, you could see uneven pad wear.

'sides.... makes it lighter.

Maybe a 3/2 arrangement?Seeing it done, I kinda thought the same thing. I think I may chuck it up and add some more holes.

Pardon my sloppy editing...

Yeah, I think that’s exactly what I’m going to have to do.

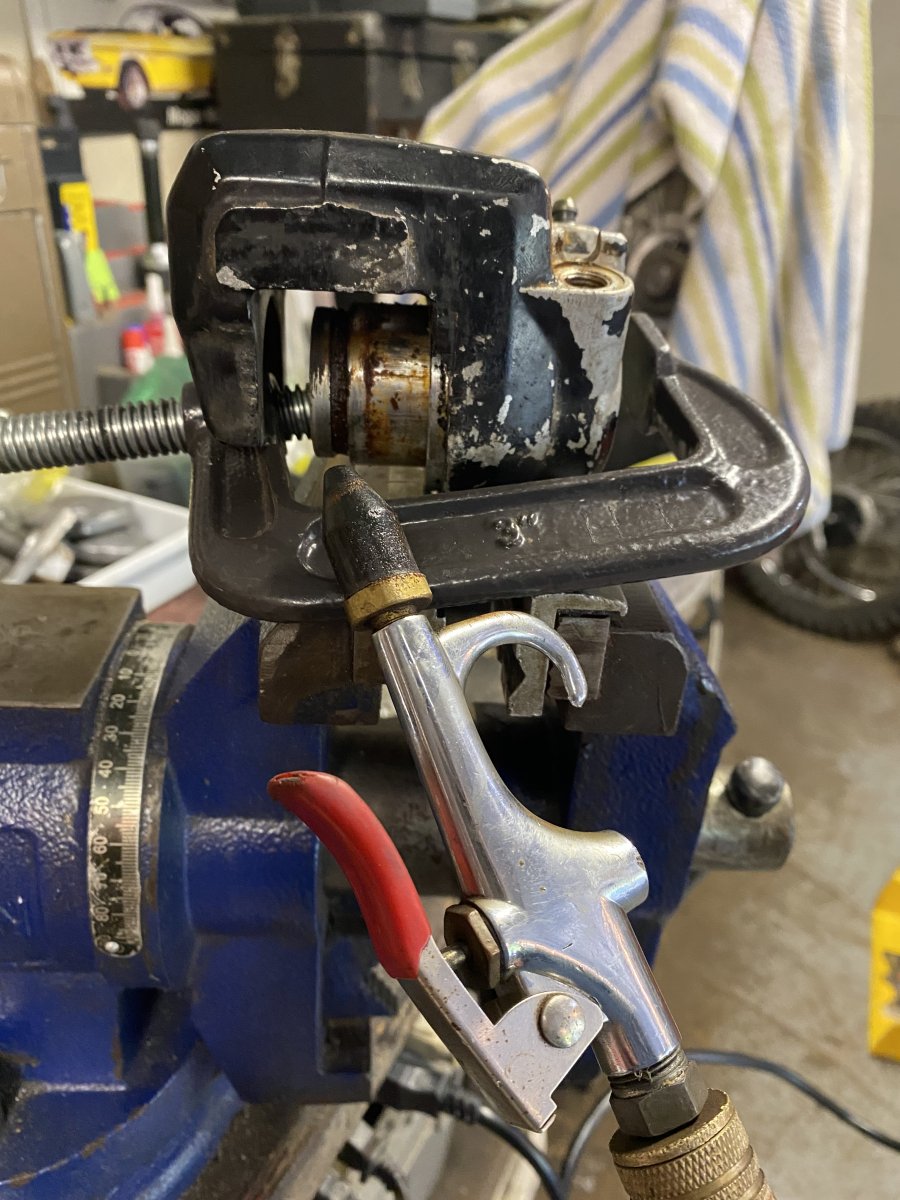

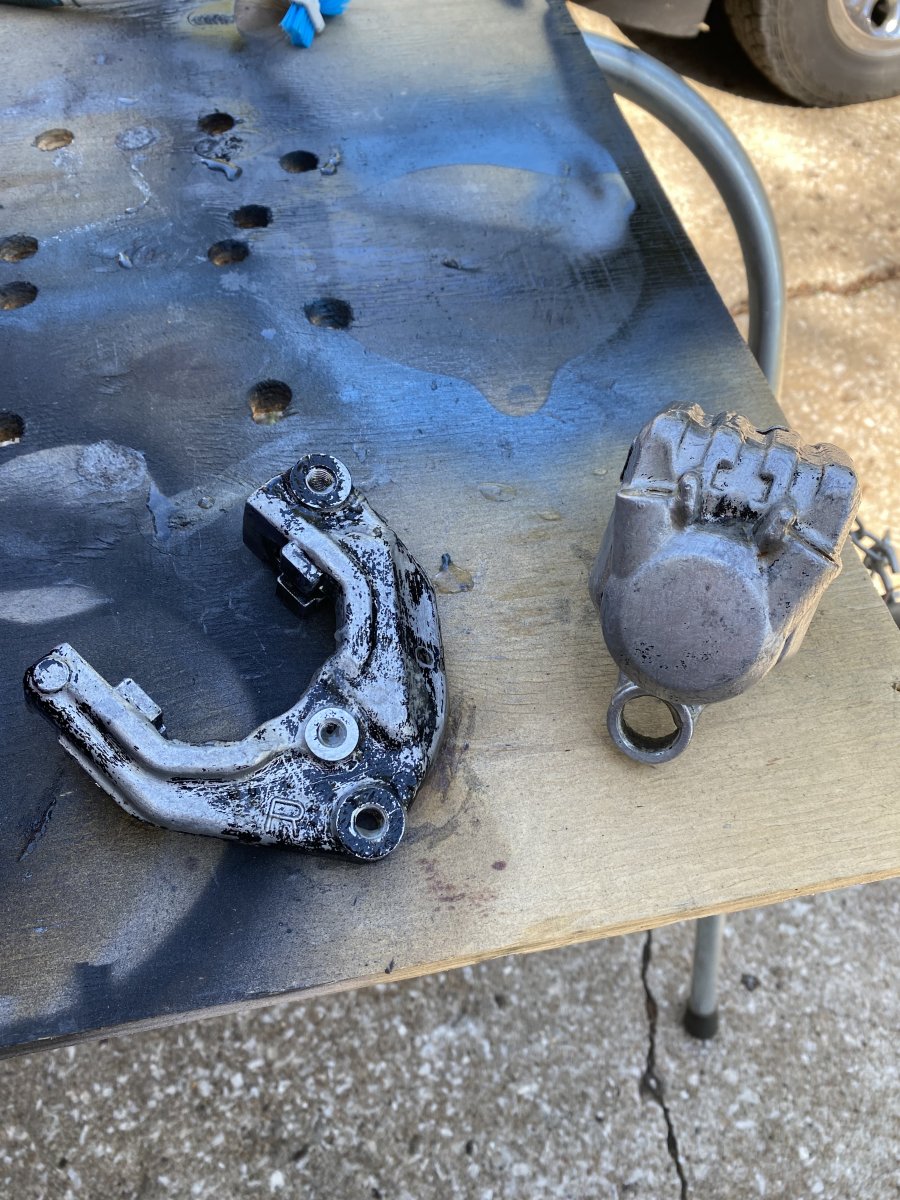

Got the caliper apart, it fought me but I prevailed. Used a heat gun and some low air pressure with a C-clamp loose to keep the piston from becoming a projectile. Took several heat cycles but it came out. I also soaked it in PB Blaster, then left it the parts washer overnight.

Started stripping all the black paint off the caliper and caliper stay.

Got the caliper apart, it fought me but I prevailed. Used a heat gun and some low air pressure with a C-clamp loose to keep the piston from becoming a projectile. Took several heat cycles but it came out. I also soaked it in PB Blaster, then left it the parts washer overnight.

View attachment 199979 View attachment 199980 View attachment 199981 View attachment 199982

c-clamp is a good idea! First time I used air to pop a piston out of a caliper I was not prepared for the reality of the situation haha. Sounded like a gun shot, launched it off the side of my barn and about 30 feet into a sandy brushed filled area. About 3 days later I finally found it by pure luck. Already had a replacement on order haha.

I may or may not have shot a few across the room.c-clamp is a good idea! First time I used air to pop a piston out of a caliper I was not prepared for the reality of the situation haha. Sounded like a gun shot, launched it off the side of my barn and about 30 feet into a sandy brushed filled area. About 3 days later I finally found it by pure luck. Already had a replacement on order haha.

By no means done, but at least I have front brakes for getting this thing on and off the “lift”

Got my 3D printed gaiter bushings.

Who did your printing?Got my 3D printed gaiter bushings.