Stan Weiss's program (

http://users.erols.com/srweiss/ ) can calculate thrust side load due to changing rod lengths.

Smokey basically said in as much to stuff the longest rod you can into a motor. Doing the math (or letting a program do it for you), you can see where the difference lies (increase tdc dwell, lower piston speed, less side thrust). The biggest, by far, advantage of a longer rod is being able to run a much lighter piston.

That being said, I don't think anyone on here is working on the level where any of that matters. The difference is small enough that being slightly off on jetting or a change in the weather will negate any difference, and practically everyone isn't using tuned length exhausts and intakes. There is a lot more power to be had there. Besides, you need a cam specially ground for the above to take advantage of pretty much everything but from friction and lighter weight and even then it's debatable. Most seem content on building motors exactly as they were 35 years ago.

Dirt racers (car and bike) use long rods to shift piston speed around which effects the way it transmits power. It's more about that and less about making more hp.

Highside's posts agree with everything I've read by high level engine builders.

Here is an example I was playing around with:

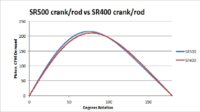

Here is a graph I made comparing a SR500 crank/rod and 87mm bore and a SR400 crank/rod and 97mm bore. It shows piston cfm demand for a given crank rotation at 7300rpm and at 44hp for both motors. I adjusted VE % in PipeMax so they had the same exact hp. It wouldn't work out this way in real life, just trying to demonstrate the differences in where the peaks occur. Keep in mind, piston cfm demand is linked to velocity of the piston.

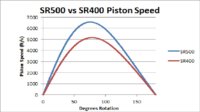

The other graph is the same set-up as above, but the y-axis is showing piston speed in ft/min for a given crank rotation. The values are for 7300rpm.

The engine specs are as follows:

SR500: 3.425" (87mm) bore, 3.307 (84mm) stroke, 5.709 (145mm) c-c length

SR400 crank/rod + 97mm bore (this is so both motors equal 500cc): 3.833" (97mm) bore, 2.640" (67mm) stroke , 6.030" (153mm) c-c length.

And one more thing Mr.Ed why don't you take a trip to Mooreville,NC to inform those NASCAR boys(Where automotive technology begins) that their usage of long rods for long tracks is pretty useless based on your Horses Ass Scientific Theories and one more thing Mr.Ed,when you start altering rod ratios or strokes,it changes pistons speed which in turn effects the vacuum draw through the ports and for someone who's claims to of been in charge of a cylinder head department should of know this from his elementary school training,after the all an engine is nothing more than big air pump. Changing strokes or Rod Ratios changes everything,IT"S THE FACTS MR.ED

And one more thing Mr.Ed why don't you take a trip to Mooreville,NC to inform those NASCAR boys(Where automotive technology begins) that their usage of long rods for long tracks is pretty useless based on your Horses Ass Scientific Theories and one more thing Mr.Ed,when you start altering rod ratios or strokes,it changes pistons speed which in turn effects the vacuum draw through the ports and for someone who's claims to of been in charge of a cylinder head department should of know this from his elementary school training,after the all an engine is nothing more than big air pump. Changing strokes or Rod Ratios changes everything,IT"S THE FACTS MR.ED