maas562

XS650 Enthusiast

Hey all, names Marshall, 21 years of age. Been lurking around here for a while on and off when I have time. Lots of info and skill. Anyways, this is my first post, so enjoy.

I picked up the bike last July. I bought it as a roller and got a motor with it as well. The frame was a 1980 and the engine I don't know what year. I'm guessing it might be a 75 based off the style cam chain tensioner that it has. The serial number is non existent so unless somebody has a tell tale way of identifying it I guess one will never know.

I didn't have any kind of vision or idea of how I wanted the bike to look when finished, I just started and was shooting from the hip as I went.

Anyways, enough blabb, onto the pics.

Here it is the day I brought it home. Frame, Motor, and a box of parts to make things work.

Tore the motor apart to check on its condition.

And Yes, I painted it before I even started fab work on the bike. I like to do things backasswards to make them harder on myself. So leave me alone. It still looks fantastic.

Except for the fact that it's apart right now and at my motor builder (I race motorcross and he does my heads) because the valves wouldn't seal, even after lapping. So he is touching up the seats and cleaning up the ports. All other work I have done.

Forward controls first prototype.

Stock Neck Cleaned Up.

Made new gussets

Welded in

Here's some pics of the exhaust all tacked up. Full 304 Stainless, 1.5" mandrel bent tubes.

After a little bit of work this is what it ended up like. It looked ok to me, but I played around some more. Keep reading.

Re-made the forward controls. Beefier and wider.

Here they are mocked up with a linkage.

The next change I made was the front end. The stock xs front end looks like sh!t IMO.

Everybody always does gsxr swaps. I really wanted to do a Buell front end swap (My other bike is a 2008 firebolt 1200, I'm a Buell freaak) so I could run the inverted caliper and rotor, but I would have had to run the wide rear wheel to match. And I didn't want to chop the frame again.

I had a crashed gsxr1 and an r1 on hand that I scored cheap. Both 2002's. I compared them both and decided the r1 work look better and work better for my setup. The rotors on the r1 are actually similar in size to the xs. The gsxr rotors were way bigger hence why everybody has issues getting them to work.

So here are some pics of the swap, I got new stem bearings from allballs and pressed them on, new wheel bearings to fit the xs wheel and r1 axle. Honda RC51 front bearings are actually the ONLY other bearings made that are the correct size, trust me I've hunted, so that's what I used. I fabricated everything else, center bearing spacer, wheel spacers, and caliper spacers.

enjoy.

Mocked up

Wheel spacers in the lathe

Finished

Left side without seals in

Right side w/o seals

Caliper spacers

Installed

It's almost as if these bikes, 22 years apart, were made for each other. Besides different size bearings, and a little bit of fab work, they work really well together. The caliper has about 3/32" of clearance from the mag spokes. It's a close fit but looks really good. I can't speak for actual spoke wheels, they might hit.

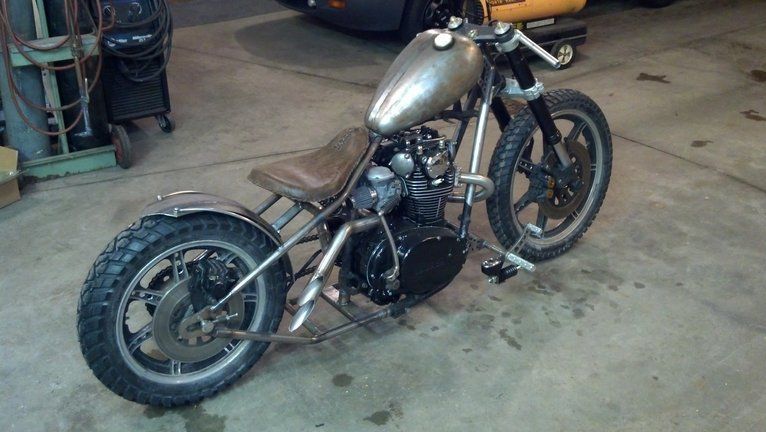

Here is the way it turned out. I'm happier with this.

You can also see the fender and supports I made from scratch. Fender isnt finished yet.

Here's me welding something

I have a ton of work left, though it looks nearly complete. I recently moved the seat further back, new mounts and I'm waiting on a new rock shox to come. The tank is going to be chopped apart in some way shape or form. I need steering stops, headlight and taillight mounts, oil tank, brake stay,rear axle spacers, exhaust mounts, install pamco and pma, send carbs to Rick at oldskool cause I don't have enough time to waste polishing them, odds and ends.. yadda yadada, blah blah.

Stay tuned, I'll be riding it by spring. Winter blows here in WISO

I picked up the bike last July. I bought it as a roller and got a motor with it as well. The frame was a 1980 and the engine I don't know what year. I'm guessing it might be a 75 based off the style cam chain tensioner that it has. The serial number is non existent so unless somebody has a tell tale way of identifying it I guess one will never know.

I didn't have any kind of vision or idea of how I wanted the bike to look when finished, I just started and was shooting from the hip as I went.

Anyways, enough blabb, onto the pics.

Here it is the day I brought it home. Frame, Motor, and a box of parts to make things work.

Tore the motor apart to check on its condition.

And Yes, I painted it before I even started fab work on the bike. I like to do things backasswards to make them harder on myself. So leave me alone. It still looks fantastic.

Except for the fact that it's apart right now and at my motor builder (I race motorcross and he does my heads) because the valves wouldn't seal, even after lapping. So he is touching up the seats and cleaning up the ports. All other work I have done.

Forward controls first prototype.

Stock Neck Cleaned Up.

Made new gussets

Welded in

Here's some pics of the exhaust all tacked up. Full 304 Stainless, 1.5" mandrel bent tubes.

After a little bit of work this is what it ended up like. It looked ok to me, but I played around some more. Keep reading.

Re-made the forward controls. Beefier and wider.

Here they are mocked up with a linkage.

The next change I made was the front end. The stock xs front end looks like sh!t IMO.

Everybody always does gsxr swaps. I really wanted to do a Buell front end swap (My other bike is a 2008 firebolt 1200, I'm a Buell freaak) so I could run the inverted caliper and rotor, but I would have had to run the wide rear wheel to match. And I didn't want to chop the frame again.

I had a crashed gsxr1 and an r1 on hand that I scored cheap. Both 2002's. I compared them both and decided the r1 work look better and work better for my setup. The rotors on the r1 are actually similar in size to the xs. The gsxr rotors were way bigger hence why everybody has issues getting them to work.

So here are some pics of the swap, I got new stem bearings from allballs and pressed them on, new wheel bearings to fit the xs wheel and r1 axle. Honda RC51 front bearings are actually the ONLY other bearings made that are the correct size, trust me I've hunted, so that's what I used. I fabricated everything else, center bearing spacer, wheel spacers, and caliper spacers.

enjoy.

Mocked up

Wheel spacers in the lathe

Finished

Left side without seals in

Right side w/o seals

Caliper spacers

Installed

It's almost as if these bikes, 22 years apart, were made for each other. Besides different size bearings, and a little bit of fab work, they work really well together. The caliper has about 3/32" of clearance from the mag spokes. It's a close fit but looks really good. I can't speak for actual spoke wheels, they might hit.

Here is the way it turned out. I'm happier with this.

You can also see the fender and supports I made from scratch. Fender isnt finished yet.

Here's me welding something

I have a ton of work left, though it looks nearly complete. I recently moved the seat further back, new mounts and I'm waiting on a new rock shox to come. The tank is going to be chopped apart in some way shape or form. I need steering stops, headlight and taillight mounts, oil tank, brake stay,rear axle spacers, exhaust mounts, install pamco and pma, send carbs to Rick at oldskool cause I don't have enough time to waste polishing them, odds and ends.. yadda yadada, blah blah.

Stay tuned, I'll be riding it by spring. Winter blows here in WISO

Last edited: