-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to tell if i have a 750 kit

- Thread starter ss243b

- Start date

I can think of a way, but you'd need a known stock bore 650 handy for the comparison...

chizler62

XS650 Addict

Find a local shop with a P&G gauge. Ohio? Pretty sure Mark Baldwin would have one.

I am Carbon

shade tree mechanic

on my 750 jugs the fins different than stock head.

Also the cam tension adjuster housing is part of jugs not bolted on like stock jugs.

take a pic of engine and post it. It might be that easy to tell.

Also the cam tension adjuster housing is part of jugs not bolted on like stock jugs.

take a pic of engine and post it. It might be that easy to tell.

scabber

XS650 Guru

A compression check should tell you if it is stock or not. My 750 is 195 stock is around 150.

DIRTY DOG

XS650 Guru

on my 750 jugs the fins different than stock head.

Also the cam tension adjuster housing is part of jugs not bolted on like stock jugs.

take a pic of engine and post it. It might be that easy to tell.

not all 750 kits use the big finn cyl block's most just put the 750 sleaves in the stock cyl.block p & g gauge is the best way with out pulling the head if it hasn't been ran yet you may look at the top of the pistons though the plug hole and see if it's marked on the top of the piston

TwoJugs

Excess XS

No way to tell unless you can measure the displacement of the stroke. Compression and appearance will give you little info. I once made a device that allowed putting heavy oil into a cylinder at BDC then measured what was pumped out going to TDC. Only way I know of without measuring bore, assuming no crank stroke mods were done.

Shine a light into the plug hole, turn the engine over until you can see the edge of the piston, if there is a small flat ridge around the edge of the piston it's taken out to 750,

Here's a couple pics of 750cc pistons that show that small flat ridge that Jay760 is talking about.

It's only about 0.100" wide. Pics are of old 256 pistons, factory and Wiseco.

Attachments

I am Carbon Too

Mobil Me

Well looking at the jugs they are stock jugs.

They may have been bored I would be surprised if bored to 750cc.

jayel

#9 Guru 74 TX650A

Well looking at the jugs they are stock jugs.

They may have been bored I would be surprised if bored to 750cc.

may not be bored but re-sleeved if someone can measure a stock 650 (piston at bottom dead center) insert a drinking straw thru the sparkplug hole to the inside cylinder wall diagonally and measure length the do the same to the supposed 750 there will be a difference due to the larger bore, guys do this all the time to check on 883/1200 Harleys

I was thinking of doing the same thing, but with the rotor mark on the 40° advance mark (a known repeatable position). This would position the piston about 7/16" (11mm) down from TDC, and may allow a thin/straight wire/rod to poke thru the plug hole, over the piston dome, stopped at the farside cylinder wall.

A reference mark would need to be made on the wire/rod at the surface of the plug hole, or a friction disc slid down the wire/rod, stopping at the plug hole. Then, measure the wire/rod length to this friction/stopper disc.

Since the wire/rod angle would be close to 45° in this test, the expected 0.100" radius increase would be only about 0.070", requiring a fair degree of precision here.

A reference mark would need to be made on the wire/rod at the surface of the plug hole, or a friction disc slid down the wire/rod, stopping at the plug hole. Then, measure the wire/rod length to this friction/stopper disc.

Since the wire/rod angle would be close to 45° in this test, the expected 0.100" radius increase would be only about 0.070", requiring a fair degree of precision here.

If you don’t have any luck with the above have a talk to someone in the aviation maintenance industry. They use borescopes (non medical endoscopes) to do inspections, and these will easily show if the piston has the flat area described above. They may even be able to measure the bore for you.

Apexdc

It's never too late to have a happy childhood!

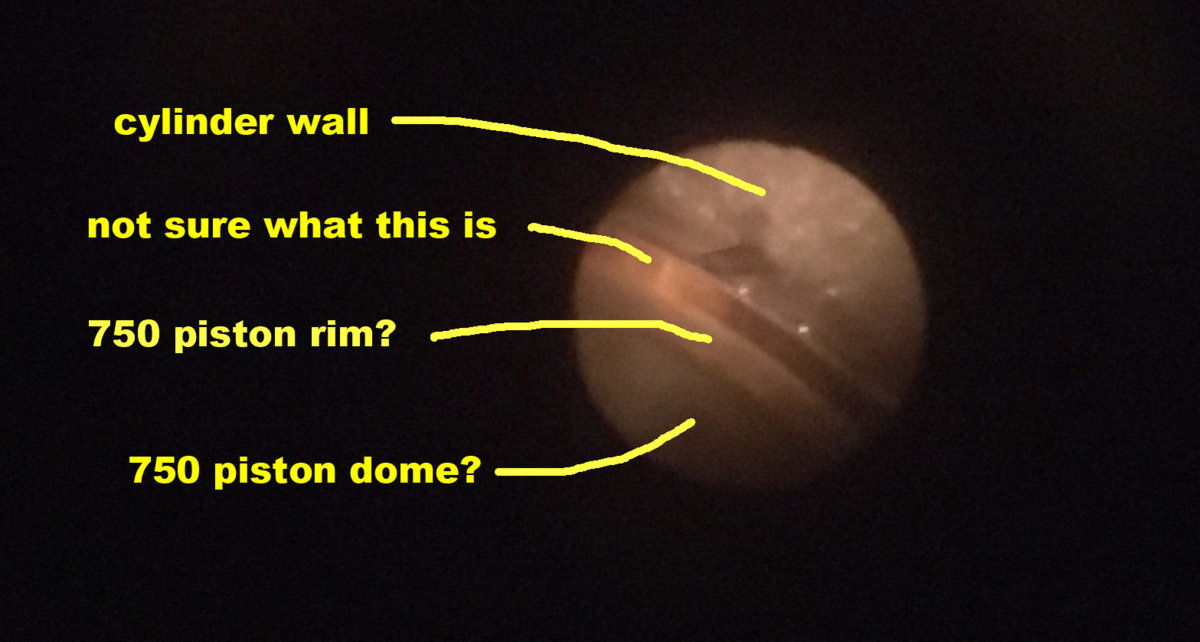

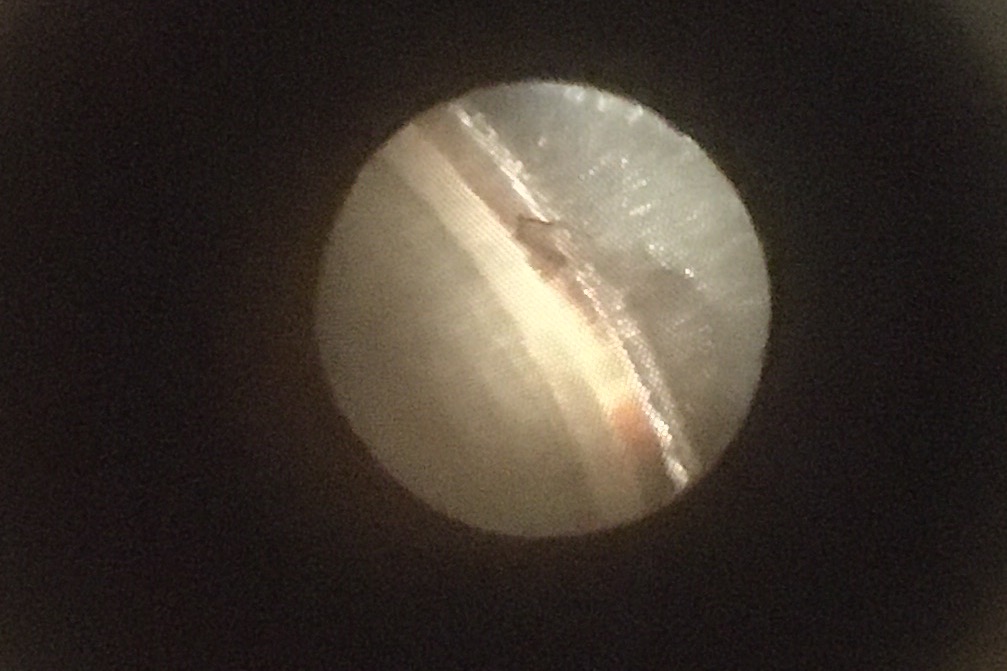

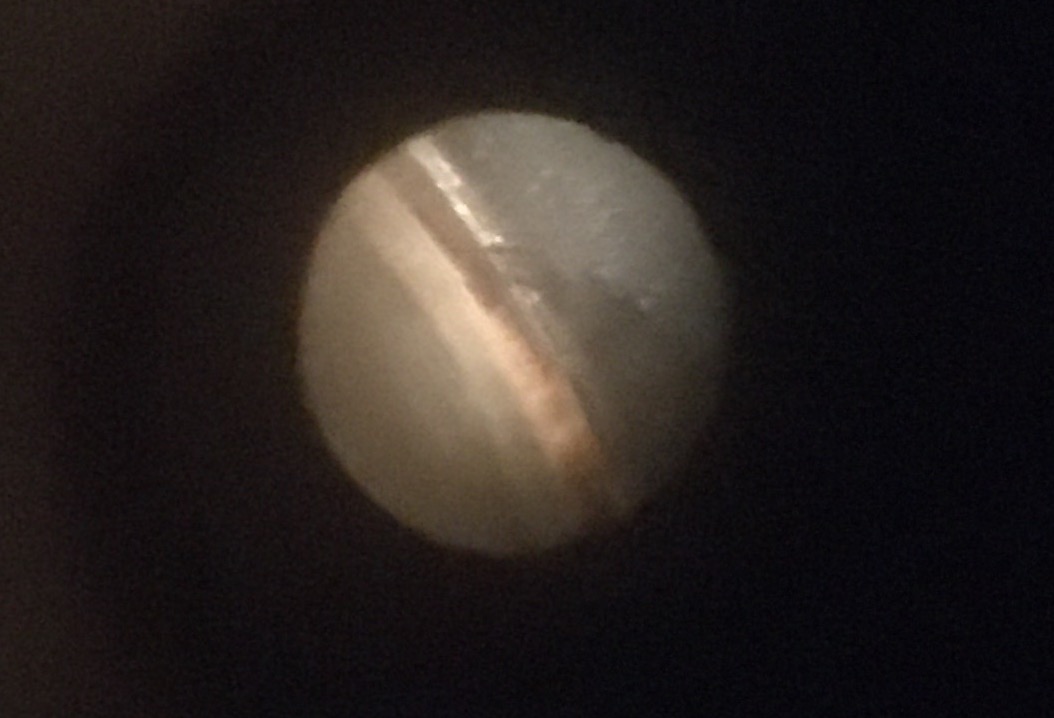

I borrowed a friends borescope and took some pix. The view through the scope was very clear, but these are not terrible. What do you guys think? I think I see the described rim of a 750 piston, but am not sure what I am looking at.

In the scope, I see the cylinder wall, then sort of a copper colored band, then another band that looks like the piston edge and then a larger field that is the dome. I have tried different angles, but it always looks the same. Thanks for the help!

In the scope, I see the cylinder wall, then sort of a copper colored band, then another band that looks like the piston edge and then a larger field that is the dome. I have tried different angles, but it always looks the same. Thanks for the help!

David, those pics sure lead one to think that you do indeed have 750 pistons.

Try this.

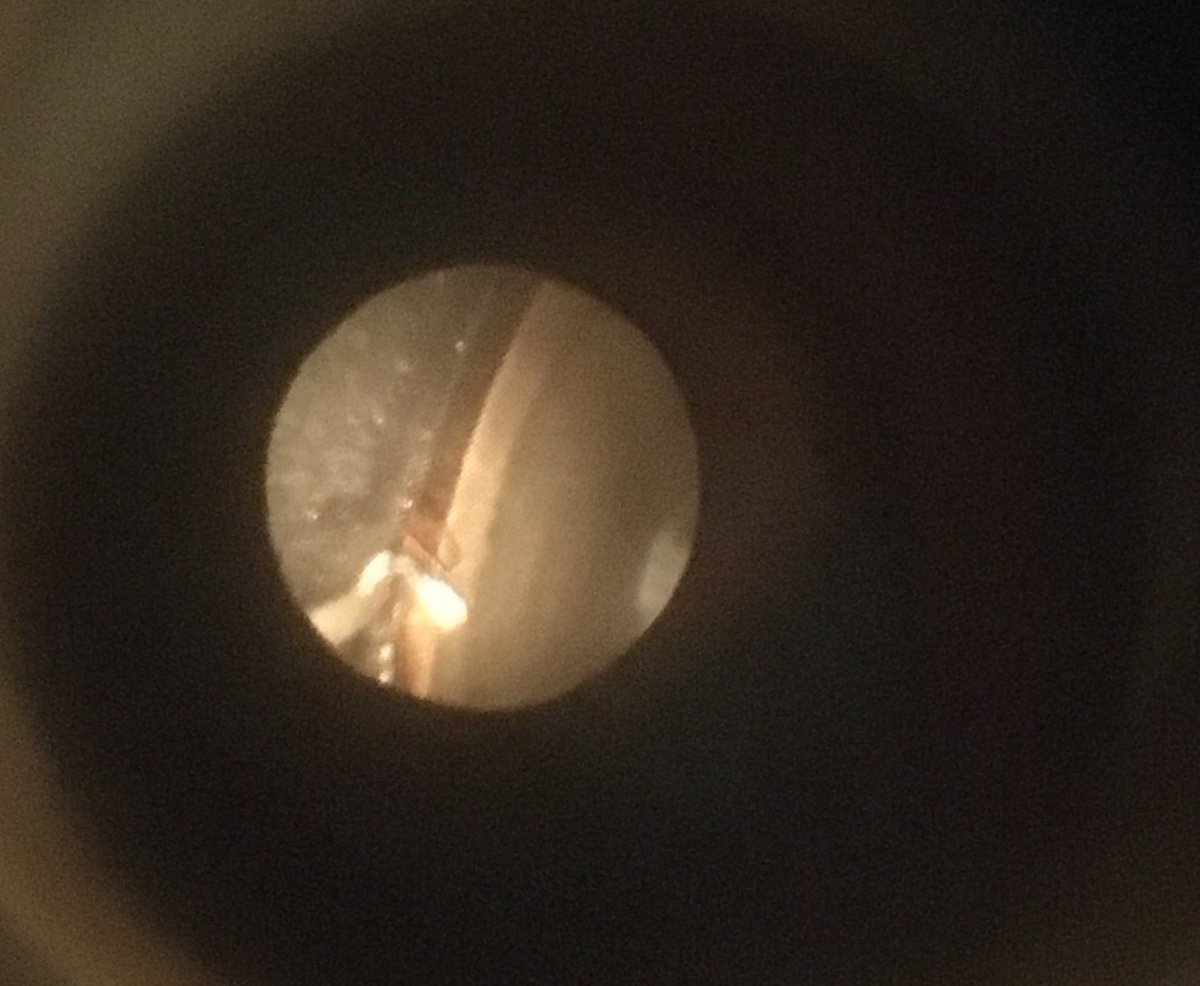

Get a long piece of fine copper wire, twist the end into a fine ball or loop, and make a solder blob there, trying to make the solder blob/ball about 0.100" (2.5mm) diameter. Thread it down into the cylinder, place atop the ledge, and boresight again. See if it's the same size as the ledge...

Try this.

Get a long piece of fine copper wire, twist the end into a fine ball or loop, and make a solder blob there, trying to make the solder blob/ball about 0.100" (2.5mm) diameter. Thread it down into the cylinder, place atop the ledge, and boresight again. See if it's the same size as the ledge...

Apexdc

It's never too late to have a happy childhood!

I took a piece of wire and flattened it so that it was 0.10" wide. It was very hard to get it into the position that I could photo it, but it looks like the rim is pretty close to 0.10. Besides, the way I understand it, the 650 doesn't have anything. So, I'm thinking it might be a 750?????

Last edited:

David, you should have enuff info now to make the determination. I'd probably need to be there to see for myself, but I'll lean towards that being an 80mm piston.

There's some pics of 75mm and 80mm pistons in this thread.

http://www.xs650.com/threads/need-help-with-piston-id.42027/

You may find the rings discussions handy...

There's some pics of 75mm and 80mm pistons in this thread.

http://www.xs650.com/threads/need-help-with-piston-id.42027/

You may find the rings discussions handy...

Correct. Can't speak for aftermarkets, but OEM's just a dome with no ridge.Besides, the way I understand it, the 650 doesn't have anything.

Last edited: