-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

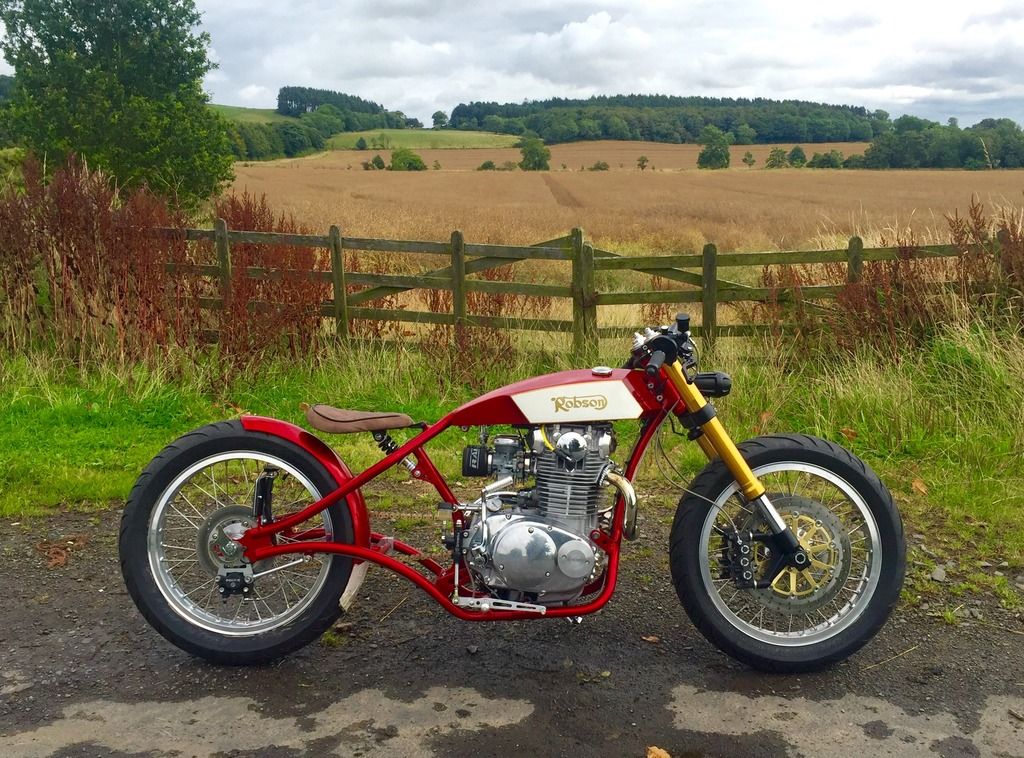

UK Board Tracker Build Thread

- Thread starter Paulrxs650

- Start date

Paulrxs650

XS650 Enthusiast

Thanks Guys! We're definitely getting there. I'm looking at the chain and I'm going to fabricate a small rubber roller to replace the nylon guard as I'm going to have a minor contacts issue as I thought. The roller will be more suited than the hard nylon to reduce any contact noise - just musing some designs

Paulrxs650

XS650 Enthusiast

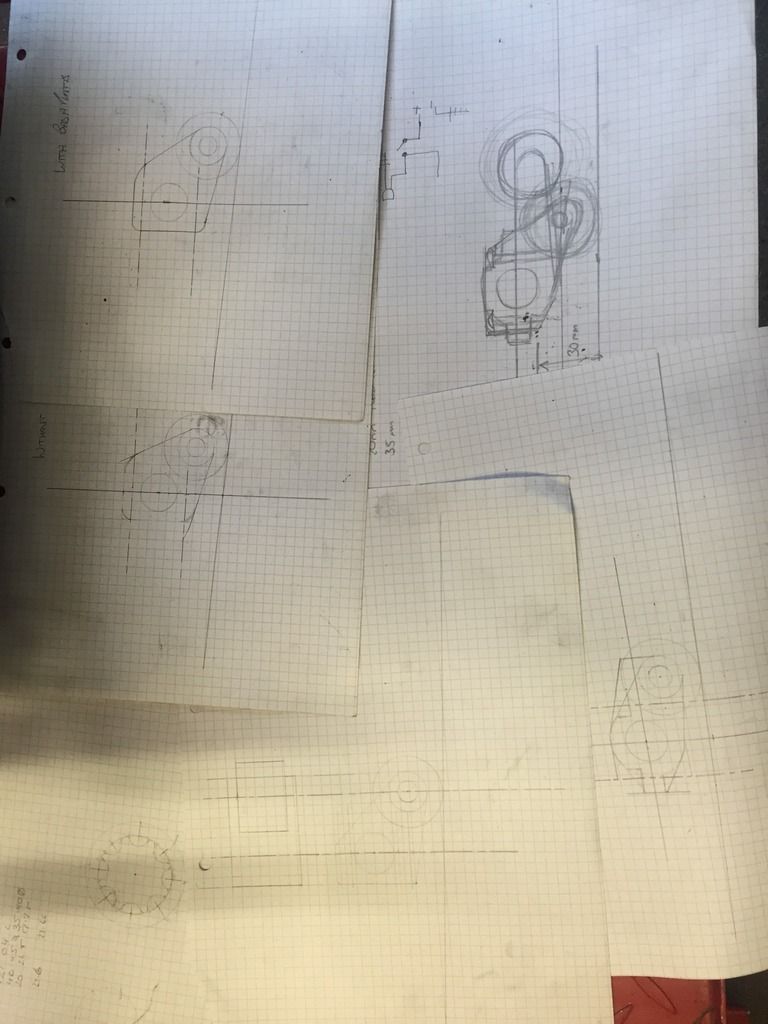

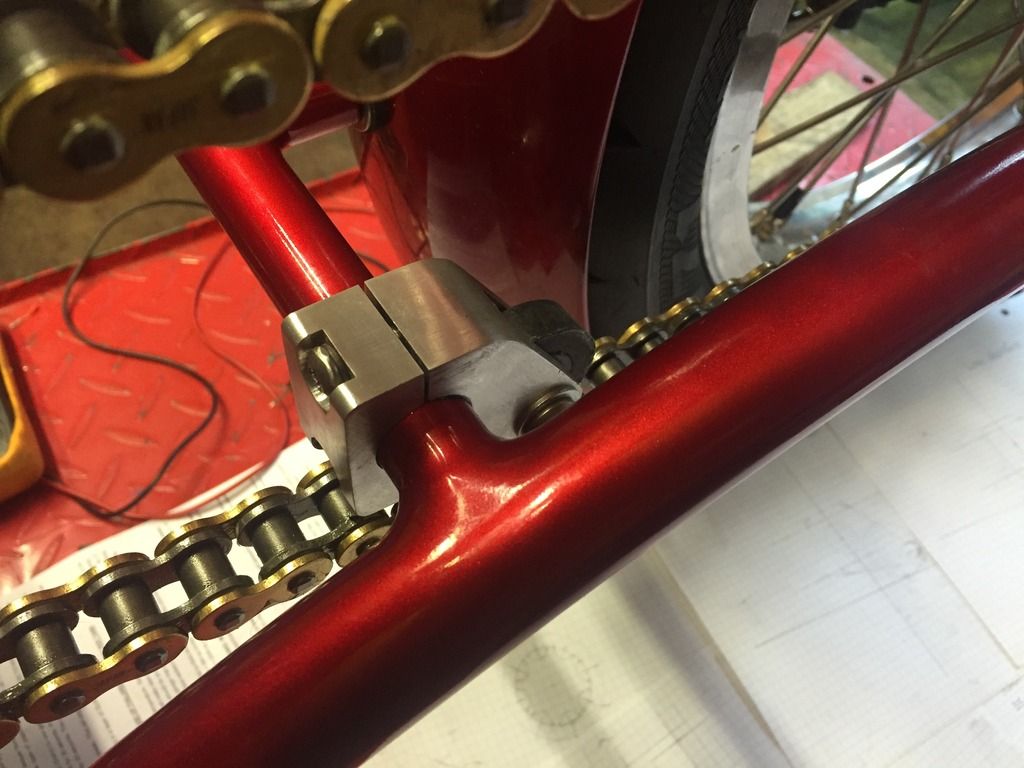

Following on from my thoughts around the nylon guard, I did a few sketches and finally settled on probably the biggest pain to make. I wanted a rubber roller, not to tension the chain specifically but to move with the chain if they met as quietly as possible. The nylon guard I made, definitely did its job protecting the frame, but produced an annoying zip like sound when contact was made. I didn't want the bulk and awkwardness of a spring tensioner, so the below is what I came up with.

Machined out of billet aluminium, a nylon wheel supported on x 2 8x16x5 bearings and wrapped in a rubber tyre:

Machined out of billet aluminium, a nylon wheel supported on x 2 8x16x5 bearings and wrapped in a rubber tyre:

Nice mount Paul, and adjustable. Curious, and you're the guy to ask, the chain has up and down motion, with slack, and not so much side to side? Side to side would probably mean some seriously worn pins and rollers.

Scott

Scott

Paulrxs650

XS650 Enthusiast

Yep - take the chain I have in here - it is new and side to side is very minimal - 1mm or so tops at the maximum length. Your right, as chains wear, they wear the rollers, pins and plates to some degree. They also develop pronounced tight spots too.

A good way to check for wear is to measure length. For example the pitch (distance between the centre of the pins) on a 530 chain is 15.88mm. If you take perhaps a digital vernier and measure over, say 20 links you want to be seeing as close to 317.60mm as possible

A good way to check for wear is to measure length. For example the pitch (distance between the centre of the pins) on a 530 chain is 15.88mm. If you take perhaps a digital vernier and measure over, say 20 links you want to be seeing as close to 317.60mm as possible

So, would you want your chain to, barely touch, always touch, not touch, only touch at tightest point, the rubber wheel?

Scott

Scott

Paulrxs650

XS650 Enthusiast

At the minute it is set just touching. I'll know more when I get it out on the road. However, the great British weather is set to piss down all weekend after being lovely all week

You have to give that thing a name,,,,,,,,,,,chain idler guide, Paul's rubber wheel, Robson wheel ?

Robson Chain Stabilizer !!!!!!!!

Scott

Robson Chain Stabilizer !!!!!!!!

Scott

Last edited:

Paulrxs650

XS650 Enthusiast

The a Robson Wheel - love it

Johnt3

Still learning...

Your my hero Paul! Nice design my friend.

Paulrxs650

XS650 Enthusiast

Thanks John

stuyvpc

XS650 Member

As always, a great looking and functional solution to a problem.

Paulrxs650

XS650 Enthusiast

Thanks stuyvpc! I got the rear light finished today. As there is a small circuit plus the tyre wires, it's not the easiest to conceal. I tried several ways but settled on looping the excess together and using some cable sock to tighten it all together. Seems to do the trick. So that's all the electrical system sorted and tested. Just need this rain to bugger off and it's testing time.

stuyvpc

XS650 Member

Love the lights in the yoke! Got my tracker in the Cheltenham festival of bikes tomorrow, shame you can't bring yours down, it would kick the arse of anything else there! Cheers, Paul

Paulrxs650

XS650 Enthusiast

Thanks! Good luck! Yeah it's a bit of a trek

buzzword

XS650 Addict

beautiful work - really fun to see this one come together!!

what top triple is this?

Paulrxs650

XS650 Enthusiast

Thanks buzzword! It's a 2014 Yamaha R1 front end - forks, top and bottom yokes

Michaelo

650Mick

Gidday Paul, I've been watching this thread of a couple of months....firstly had to read from the start and then keep on going with it. Your attention to detail is exceptional and you should be one proud man, finished bike is awesome mate and a credit to you....

When reading through, I see you have taken the time to respond to everyone too, that takes time, looking forward to your posts and I hope the weather is kind to you so you can enjoy your workmanship......

cheers Mick

When reading through, I see you have taken the time to respond to everyone too, that takes time, looking forward to your posts and I hope the weather is kind to you so you can enjoy your workmanship......

cheers Mick

Paulrxs650

XS650 Enthusiast

Hi Michaelo, thanks very much for the very kind words - definitely appreciated! We have been out today, between showers and apart from a little clearance issue on the rear mudguard, all has gone well and we have 11 miles so far. I did take some photos and even got a fly by video, which I'll put up later on. Thanks again

Paulrxs650

XS650 Enthusiast

Here's some pics out and about. Also a "fly by" video