Guyz, this is monumental. Youse could be on the cusp of uncovering the anomaly that has been plaguing untold numbers of bikes with linked carbs that have idle problems...

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My 60th birthday present

- Thread starter Mailman

- Start date

-

- Tags

- 1977 xs 650d chain and sprockets clutch pushrod seal cranckcase seal new front master cylinder pamco e-advance pamco ultimate high output ignition rebuild brake caliper rebuild brakes rebuilt carburetors replace clutch solid state rectifier stainless steel braid front brake line starter gear fix steering head bearings vr-115 regulator

As I mentioned, mine idles like that, a little rougher on the left, always has. I don't recall finding a large amount of wear on the left side of my left carb's bore, a little rub mark maybe but that was all.

It's makes me want to pull and look at the restomod's 79 carbs, it runs SO sweetly, but um not right now.... Still fighting focus on that camera a bit.

TimeMachine

SeventyEighte

Hello you XS "frustrated" friends. I feel the pain .. Jeex its hard to have these XS's , right? I know many of you have a "hop on go to" bike Take a Ride ! .. It's Summer ! Morning rides change the whole out look .. Getting back in the cycle shed very soon myself, but can't sacrifice the riding pleasure right now.. We all know a well running XS650 is the ultimate ! Get there when its Fun to ! Enjoy -RT

That seems kinda mean here TM! But in the spirit of piling on JP and I took the 79 XS's out for 100 plus miles of backroads yesterday, a good time for sure. Warm enough for mesh jackets, a couple of very short rain showers felt good and cleaned the face shields.

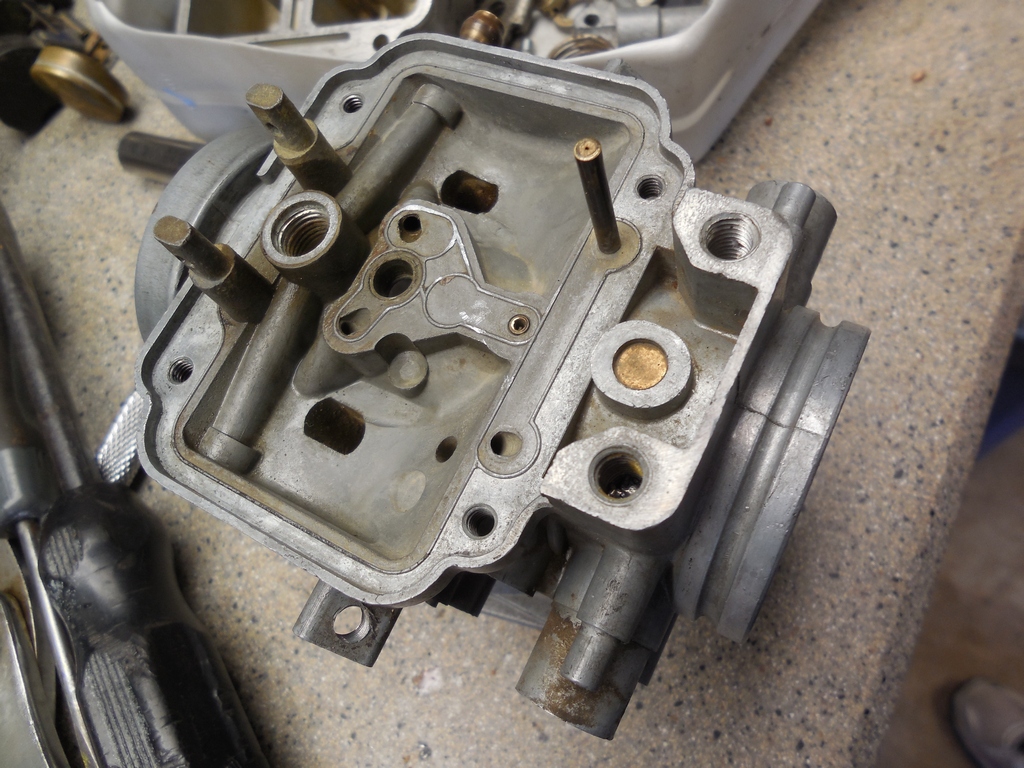

This is a left hand 78, cleaned and buffed with rubbing compound, to help reveal the wear groove. Throttle shaft out of this carb just went to a member in SD. I'd call this typical for "most of" the BS38's I have.

I would expect this carb to run an engine with no issues.

Mailmans carb.

That's a BIG difference in wear. Guess I need to see how much "shaft wiggle" he has also. Um let me rephrase that.....

This is a left hand 78, cleaned and buffed with rubbing compound, to help reveal the wear groove. Throttle shaft out of this carb just went to a member in SD. I'd call this typical for "most of" the BS38's I have.

I would expect this carb to run an engine with no issues.

Mailmans carb.

That's a BIG difference in wear. Guess I need to see how much "shaft wiggle" he has also. Um let me rephrase that.....

Last edited:

I'd call this typical for "most of" the BS38's I have.

View attachment 102373

I would expect this carb to run an engine with no issues.

Yeah that looks like more of a scuff compared to the groove in my carburetor.

If I may, I'd like to share how I'd attack this.

Starting with a piece of 8mm spacer, perhaps 5/8"-3/4" OD, make sure that one end is squared-off, flat. Then cut a piece of #180-#220 wet-or-dry to cover the end.

Glue the sandpaper to the spacer.

Trim out the hole with an Xacto knife.

Chamfer the edge.

Use an 8mm shaft as a guide.

Could be a valve stem, clutch pushrod, or the throttle shaft.

Fit this new "facing tool", and sand down the throttle shaft bore's extension.

Remove all roughness.

Fit the facing tool over the throttle shaft,

and clean the worn surface of the nylon spacer.

I'd recommend a stainless steel thrust washer.

8mm (or 5/16", if it fits) ID, unknown OD.

Thickness of 0.2-0.3mm (0.008"-0.012").

This thrust washer thickness will be thick enough to stay flat, and thin enough to replace the removed material and shouldn't displace the shaft very far...

Starting with a piece of 8mm spacer, perhaps 5/8"-3/4" OD, make sure that one end is squared-off, flat. Then cut a piece of #180-#220 wet-or-dry to cover the end.

Glue the sandpaper to the spacer.

Trim out the hole with an Xacto knife.

Chamfer the edge.

Use an 8mm shaft as a guide.

Could be a valve stem, clutch pushrod, or the throttle shaft.

Fit this new "facing tool", and sand down the throttle shaft bore's extension.

Remove all roughness.

Fit the facing tool over the throttle shaft,

and clean the worn surface of the nylon spacer.

I'd recommend a stainless steel thrust washer.

8mm (or 5/16", if it fits) ID, unknown OD.

Thickness of 0.2-0.3mm (0.008"-0.012").

This thrust washer thickness will be thick enough to stay flat, and thin enough to replace the removed material and shouldn't displace the shaft very far...

Got a LH 76 here's some pics, can strip it down.

and uhh "most" of my loose 76 to 79 carbs. 78-79 on left 76-77 on right

and uhh "most" of my loose 76 to 79 carbs. 78-79 on left 76-77 on right

Anybody have any ideas on filler material for the wear grooves?

The carb bodies are most likely Zamak. Thermal expansion rate very similar to aluminum. Not sure about adhesion, but I've heard of tuners using some form of epoxy to build-up inlet ports for flowbench work...

The carb bodies are most likely Zamak. Thermal expansion rate very similar to aluminum. Not sure about adhesion, but I've heard of tuners using some form of epoxy to build-up inlet ports for flowbench work...

jb weld? Get original formula not the more commonly seen fast set.

What about a wave washer for a RH spacer?

What about a wave washer for a RH spacer?

...jb weld? Get original formula not the more commonly seen fast set.

I've successfully JB-welded (original formula) a couple of Zamac parts on my lathe. It won't handle heavy loads, but it seems to stick fine. So, I've only used it for non-structural repair on Zamak.

...What about a wave washer for a RH spacer?

I'd prefer a flat washer to avoid any chance of lateral movement...

2M,

Thank you for your usual thoughtful and thorough response to this. I always enjoy the way you approach a problem like a machinist. You always think of how you can keep things straight and true. Those are some very good ideas there.

Truth be told I might of might have hit the throttle shaft bore extension lightly with some sandpaper just to smooth it up a little. I had a pretty well worn peice of 800 grit wet sand paper and I think I used it to polish it up some. I know for sure I didn't remove much.

Thank you for your usual thoughtful and thorough response to this. I always enjoy the way you approach a problem like a machinist. You always think of how you can keep things straight and true. Those are some very good ideas there.

Truth be told I might of might have hit the throttle shaft bore extension lightly with some sandpaper just to smooth it up a little. I had a pretty well worn peice of 800 grit wet sand paper and I think I used it to polish it up some. I know for sure I didn't remove much.

Will go out tomorrow.

TimeMachine

SeventyEighte

gggGary 's parts stash rocks ! Nice -RT

Thanks Gary! You are the man!

Bob

Bob

Here a pics of four of mine. The first and third are from bikes with approx 20K miles the other two are xtras.

None have the wear yours is showing.

Attachments

I decided to send along a butterfly with the carb body. If the body is THAT worn it would seem the edge of brass plate must also be the worse for wear in that area. Would like to hear see a close A-B comparison of the butterflies. Kinda brings up the issue of any groove filler/repair material being TOO hard as a bad idea.... not to mention forming it, if it's much harder than the carb body will be tough.

Thanks Gary, your thoughtfulness is much appreciated.

I'm thinking Teflon against Nylon, it makes a very good, long lasting thrust bearing, no lubrication needed. Each side of the butterfly as a spacer and thrust bearing. Not enough space to do that, right?

Scott

Scott

Last edited:

Similar threads

- Replies

- 785

- Views

- 81K

- Replies

- 3

- Views

- 2K

- Replies

- 1

- Views

- 2K