+1 - and please note that those are not simply normal 6 mm screws.

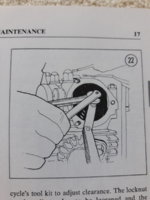

The bottom end which bears on the top of the valve stem is hardened and has a special profile which is required for the valve to operate correctly.

When I got my 1976 C model, one of those square ends was busted right off - don't know where it went... - so I replaced all four of the adjuster screws with Allen head adjuster screws from MikesXS - and haven't had any difficulty since.

- so I replaced all four of the adjuster screws with Allen head adjuster screws from MikesXS - and haven't had any difficulty since.

Many people use a valve adjuster screw from VW air-cooled engines or a certain model of Porsche engine which fits perfectly - and apparently, they work very well too (although there are reports of counterfeit parts around).

p

The bottom end which bears on the top of the valve stem is hardened and has a special profile which is required for the valve to operate correctly.

When I got my 1976 C model, one of those square ends was busted right off - don't know where it went...

- so I replaced all four of the adjuster screws with Allen head adjuster screws from MikesXS - and haven't had any difficulty since.

- so I replaced all four of the adjuster screws with Allen head adjuster screws from MikesXS - and haven't had any difficulty since. Many people use a valve adjuster screw from VW air-cooled engines or a certain model of Porsche engine which fits perfectly - and apparently, they work very well too (although there are reports of counterfeit parts around).

p