Ah, red rubber grease. I believe you've got it, 5T.

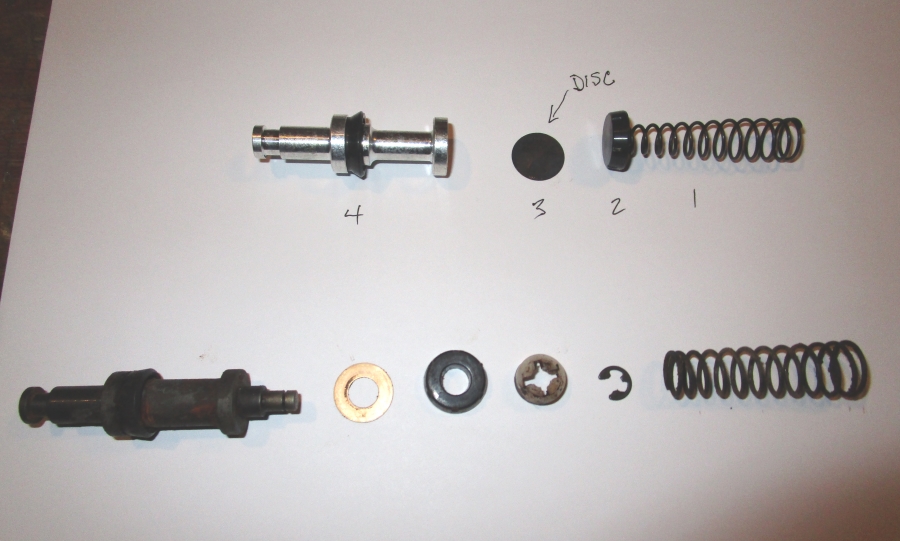

This could have been an item in my "What the Heck is it?" thread.

Last night I spent some time reading about various assembly lubes on racer/mechanic forums, but they tended to be controversial, with some mechanic always making a case against this or that product. Syl-glide, for example; lots of discussion about that at our website.

But this grease looks good; I'll read more about it.

Here is what is offered at redrubbergrease.com :

"Rubber without lubrication dries out, hardens, crackles and breaks. If affected by gasoline or if lubricated with petroleum-based grease, it swells, loses its shape and does not do the work as intended. When in contact with moving parts, it wears out from friction (an o-ring against a brake caliper or cylinder piston, a dust boot against a clutch plunger) and also may rupture. And, finally, during assembly, it is hard to push a piece of dry rubber into a casing and even more so to slide one rubber part onto another.

To help in all of the above situations red grease was designed, Castrol RRG being one of the best known brands. Being a vegetable oil based lubricant this grease does not harm rubber and can be used for its protection, lubrication and preservation. It can also be a great help during assembly of units containing parts made of natural or synthetic rubber and even plastic (installing bushings, for example).

Because of a unique combination of two of its qualities: natural rubber compatibility and brake fluid compatibility the main use of Red Rubber Grease is in hydraulic brake/clutch applications.

Red rubber grease uses.

Because of the qualities mentioned above Red Rubber Grease it is ideal for use in hydraulic systems, namely, hydraulic brakes and clutches or shock absorbers, pneumatic systems containing rubber parts (o-ring, seals). For this reason a sachet of the red grease comes as a standard part of quality brake/clutch and motorcycle fork oil seal and dust seal repair kits.

In contrast to regular automotive lubricants that are petroleum-based, red rubber grease is vegetable oil based (red dye is added for identification purposes) - this is the reason why it's "rubber friendly". Being that, RRG can be used where ever natural rubber is used in the car (see some applications mentioned on this site.)

Here is a comprehensive list of RRG properties:

- Fully compatible with natural and synthetic rubbers

- Compatible with brake fluids and some hydraulic oils.

- Rust inhibitor (protects from oxidation and rust).

- RRG is water resistant.

- Hight temperarure. The grease can be used in applications with temperatures up to 210-230F. It will not melt and will not contaminate brake pads.

- Petrol resistant. Although it will get contaminated in contact with gasoline, but still it will protect rubber parts from it.

- High chemical and structural(mechanical) stability.

- High resistance against water washing (will stay on after a rain, or car wash).

- Has high wear protecting quality.

A few tips to keep in mind while rebuilding brake calipers.

To make the assembly of parts easier and ensure their long life, use red rubber grease for lubricating all rubber components of the calipers. Sometimes a sachet of red rubber grease is provided by the manufacturer together with the caliper rebuild kit. Most of the time the amount of grease provided is not enough. We recommend buying 1 ounce can of red rubber. This amount is enough for the job and you will not be tempted to use old grease and, probably dirty by then, if you buy a large can.

Lubricate piston seal with red rubber grease.

Smear inside of the caliper with grease.

Smear some grease on caliper piston.

Pack the dust boot with grease.

Now you are ready to start the assembly. Here, we are putting together a brake caliper from Triumph GT-6.

Insert the seal into the grove of the caliper bore.

Push the piston inside the caliper bore. We recommend to do this with your hands. Using a C-clamp or some other device to force the piston into the caliper may jam the piston and damage it or, alternatively, damage the walls of the caliper or piston seal or dust boot. Using rubber grease will make inserting the piston into the caliper very easy with your hands. Just push it down gently and make sure it is square in the bore. Once, the piston is half way in, place the dust boot around the piston and inset the dust boot lip into the grove in the piston. (By the way, be careful when puling the pistons out of the caliper during disassembly and don't damage the lip of the piston. A damaged lip may not seal well or, if it has sharp burrs it may rupture the dust boot.)

Push the piston in.

Wipe off the excess of grease from the caliper, dust boot and the piston. The job is done."