I wonder if the fuel is getting to the carbs to keep up? Like 5twins suggest a fuel level. Could it be that fuel line or tank outlet partially plugged? Just a suggestion. Starts, runs, enricher is let off dies. I would do a flow test from petcock to see how much comes out when open.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

XS650 Oddity

- Thread starter Mickster

- Start date

Yeah... and don't forget there's screens on the float valves. Pop the bowl drains and check flow there also.I would do a flow test from petcock to see how much comes out when open.

Newagerocker

XS650 Addict

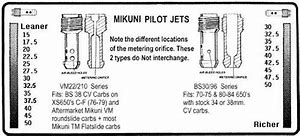

You say you have a #30 pilot but is it the appropriate type for your carbs there are two. See chart below.

Mickster

XS650 Enthusiast

Newagerocker (cool avatar), I have the jets on the left of your pic, 2 holes on 4 sides. The old 27.5 and the new 30 are the same in appearance. I miked them and the length is the same.

Yanked the carbs again, checked the jet sizes to make sure and they are A-OK, put in the 142.5 main. On paper it all seems to be good, it's almost rocket science, but it is still a carb.

Been fooling with the Pilot screw and no change. Warm it up. Been fooling with the outside Idle speed screw and no change. Kick it, starts right up, a few seconds later it coughs and stops.

Rerouted the fuel lines. Very Big question however. The fuel lines on the way from the petcock dip down, then go up (but not higher than the petcock) and back down again to the carbs. I'm not a plumber but is that an issue for fuel to flow to it's destination point?

So now, after it warms up. Kick start it on first kick, runs for about 3-4 seconds and stops. Give it some throttle and it stops right away. And on top of that some new squeaking sound is coming out of somewhere, not a carb pop, just a squeak somewhere, whatever.

I'm running out of gas on this one.

What ever happened to the technology of the old S&S Super B where it worked like charm on anything you put it on?

Anyway, I'm thinking to pull the carbs, move the needle to rich up the mail jet a bit and try again. What do you guys think?

Yanked the carbs again, checked the jet sizes to make sure and they are A-OK, put in the 142.5 main. On paper it all seems to be good, it's almost rocket science, but it is still a carb.

Been fooling with the Pilot screw and no change. Warm it up. Been fooling with the outside Idle speed screw and no change. Kick it, starts right up, a few seconds later it coughs and stops.

Rerouted the fuel lines. Very Big question however. The fuel lines on the way from the petcock dip down, then go up (but not higher than the petcock) and back down again to the carbs. I'm not a plumber but is that an issue for fuel to flow to it's destination point?

So now, after it warms up. Kick start it on first kick, runs for about 3-4 seconds and stops. Give it some throttle and it stops right away. And on top of that some new squeaking sound is coming out of somewhere, not a carb pop, just a squeak somewhere, whatever.

I'm running out of gas on this one.

What ever happened to the technology of the old S&S Super B where it worked like charm on anything you put it on?

Anyway, I'm thinking to pull the carbs, move the needle to rich up the mail jet a bit and try again. What do you guys think?

Newagerocker

XS650 Addict

Thanks my mild café still gets a lot of eyeballs when I ride it.

Does your tank have vacuum petcock? Leave in prime position when troubleshooting. Fuel lines sound a bit wonky should be gravity feed into carbs.. If you truly have 78-79 carbs, stock configuration is 135 mains, 27.5, pilot about 2.25 turns out from lightly seated. Usually go up a step for each modification, intake and exhaust upgrade cant see you needing a bigger than 140 main and 30 pilot.

Does your tank have vacuum petcock? Leave in prime position when troubleshooting. Fuel lines sound a bit wonky should be gravity feed into carbs.. If you truly have 78-79 carbs, stock configuration is 135 mains, 27.5, pilot about 2.25 turns out from lightly seated. Usually go up a step for each modification, intake and exhaust upgrade cant see you needing a bigger than 140 main and 30 pilot.

Newagerocker (cool avatar), The fuel lines on the way from the petcock dip down, then go up (but not higher than the petcock) and back down again to the carbs. I'm not a plumber but is that an issue for fuel to flow to it's destination point?

yes that's an issue, about guarantees an air bubble lock.

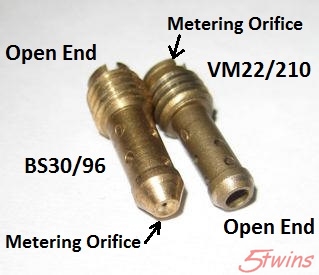

The air holes in the sides of the pilot jets aren't what you look at to I.D. their type, you look at which end the metering orifice is in. Your '78-'79 carbs use the VM22/210 type pilot and it's metering orifice should be at the top, by the screwdriver slot. The other type, the BS30/96 style, has the metering orifice at the bottom. Although the two types will physically interchange, they don't flow the same. You must use the type your float bowl was designed for.

Oddjob

adsgads

If you can, check the float level using clear tubing hooked up to your bowl drain...

Pic courtesy of 5twins...

Pic courtesy of 5twins...

If you can, observe that fuel level with the clear tube while the bike sits there idling. That should show you if the bowl is being drained but not re-filling, or over-filling. Over-filling will choke out the cylinder and stall it too.

Mickster

XS650 Enthusiast

There may be light at the end of this tunnel.

The pilot jet (30) looks just like the VM22/210 in the picture. I got new fuel lines, rerouted them so gas from the tank to the carbs flows downhill with no weird kinks or bends. Looks pretty good actually. Checked the floats again and they seem good, gas is flowing just fine.

Changed the needle position to the 4th from top, 142.5 jet, 2 turns out on the pilot screw.

Starts right up. Idles just fine. Revs up good. All that business with the thing gagging, dying and choking is gone.

Took it for a test ride.

There is a flat spot at about 1/3 throttle when the bike is under load, in neutral I can rev it just fine, in gear as I roll on the gas it'll hesitate then catch and take off.

Should I move the needle to the 5th from top notch? Or is there some other way to tweak this.

Thanks for all your help guys. I see some light at the end of this tunnel.

The pilot jet (30) looks just like the VM22/210 in the picture. I got new fuel lines, rerouted them so gas from the tank to the carbs flows downhill with no weird kinks or bends. Looks pretty good actually. Checked the floats again and they seem good, gas is flowing just fine.

Changed the needle position to the 4th from top, 142.5 jet, 2 turns out on the pilot screw.

Starts right up. Idles just fine. Revs up good. All that business with the thing gagging, dying and choking is gone.

Took it for a test ride.

There is a flat spot at about 1/3 throttle when the bike is under load, in neutral I can rev it just fine, in gear as I roll on the gas it'll hesitate then catch and take off.

Should I move the needle to the 5th from top notch? Or is there some other way to tweak this.

Thanks for all your help guys. I see some light at the end of this tunnel.

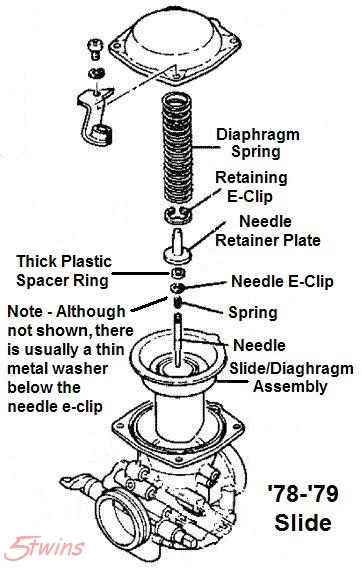

Well, whatever works for your bike I guess, but your needle setting is not the norm. You should probably verify that the needle and needle jet are the stock ones. That would be a 5O2 needle and a Z-2 needle jet. Stock clip position was in the middle (#3) slot and as I mentioned, this carb set pretty much always requires leaning the needle a step when you install larger mains. Having to set the needle so rich is odd, to say the least. Make sure you have it assembled properly in the slide. The small spring on the needle goes under the e-clip and spacer washers, not on top, and the thick plastic spacer washer goes on top of the e-clip .....

If you placed the little spring on top of the e-clip and spacer washers, that would have the needle sitting too low (lean) in the slide. That could explain the need to set the e-clip in such a low (rich) slot.

If you placed the little spring on top of the e-clip and spacer washers, that would have the needle sitting too low (lean) in the slide. That could explain the need to set the e-clip in such a low (rich) slot.

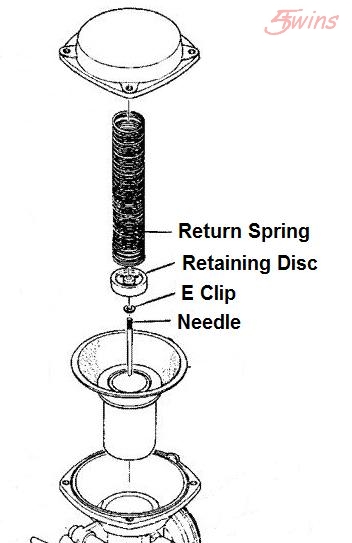

Another possibility has come to mind - you may have the wrong slides fitted in your carbs. The earlier '70-'77 carbs used a different slide than the '78-'79 set. The difference is in how the needle mounted. On the early slide, the needle drops right into the bottom of it and is held in by a large plastic disc. The big slide return spring holds it all down in there .....

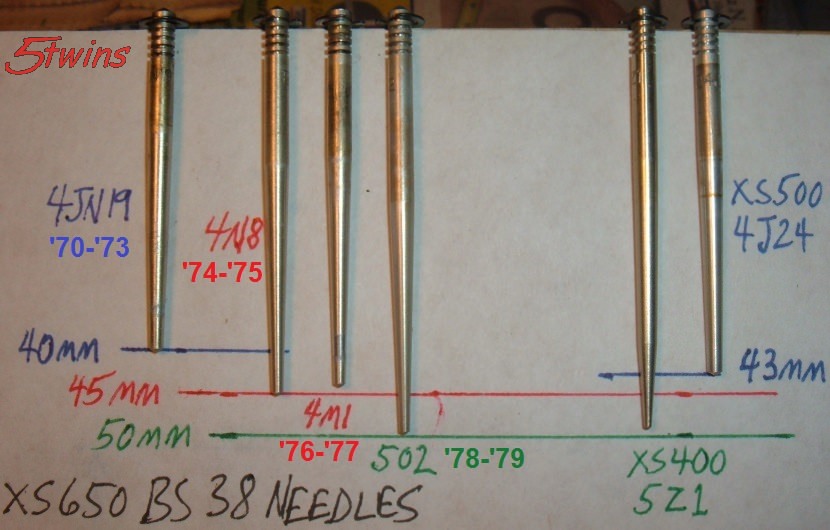

The '78-'79 slide has a sort of golf tee shaped retainer over the needle held down into the slide by a snap ring. The new design incorporates a spring-loaded needle which meters more precisely and was probably done to help meet tightening E.P.A. regs. But, to make room for that spring, the needle had to mount up higher in the slide, which means it had to be longer than the early needles. Here's the various BS38 needles compared and as you can see, the early ones are shorter, really a lot shorter in the case of the '70-'73 4JN19 .....

If someone fitted early slides but with the longer '78-'79 5O2 needle, it would hang out the bottom of that early slide too much and be too lean.

The '78-'79 slide has a sort of golf tee shaped retainer over the needle held down into the slide by a snap ring. The new design incorporates a spring-loaded needle which meters more precisely and was probably done to help meet tightening E.P.A. regs. But, to make room for that spring, the needle had to mount up higher in the slide, which means it had to be longer than the early needles. Here's the various BS38 needles compared and as you can see, the early ones are shorter, really a lot shorter in the case of the '70-'73 4JN19 .....

If someone fitted early slides but with the longer '78-'79 5O2 needle, it would hang out the bottom of that early slide too much and be too lean.

Mickster

XS650 Enthusiast

5twins, Wow, that's a lot of complexity. I think I have normal carbs because they look like the illustration you posted. Golf tee and all.

I put the carbs back together the same way they were when I first got the bike and needed to disassemble and clean the carbs.

That spacer/washer, unless it is stuck inside the slide body, has never been seen and maybe doesn't even exist.

The way mine are put together is the needle, needle clip and plastic spacer on top of the clip are dropped into the slide body as an assembly. Then the spring is dropped in. Then the golf tee retainer plate and lastly the retaining e-clip is installed.

So the order from top down is:

Retaining e-clip

Needle retainer plate

Spring

Thick plastic spacer

Needle e-clip

Which is different than the illustration. The missing spacer/washer would explain some things wouldn't it. Does the spring go between the spacer/washer and needle e-clip? Or below both?

BTW, You nailed it dude!

I put the carbs back together the same way they were when I first got the bike and needed to disassemble and clean the carbs.

That spacer/washer, unless it is stuck inside the slide body, has never been seen and maybe doesn't even exist.

The way mine are put together is the needle, needle clip and plastic spacer on top of the clip are dropped into the slide body as an assembly. Then the spring is dropped in. Then the golf tee retainer plate and lastly the retaining e-clip is installed.

So the order from top down is:

Retaining e-clip

Needle retainer plate

Spring

Thick plastic spacer

Needle e-clip

Which is different than the illustration. The missing spacer/washer would explain some things wouldn't it. Does the spring go between the spacer/washer and needle e-clip? Or below both?

BTW, You nailed it dude!

If you placed the little spring on top of the e-clip and spacer washers, that would have the needle sitting too low (lean) in the slide. That could explain the need to set the e-clip in such a low (rich) slot.

That's your problem then, the spring is in the wrong spot. It should be 1st in the slide, under all the needle parts (e-clip and spacer washers). You may need to find some small flat washers for under the e-clips so the open ends of the clips aren't catching on the springs.

Mickster

XS650 Enthusiast

Thanks 5twins.

Took the carbs off and disassembled. Before I put these things back together and mounted, again, I want to make sure I got it right.

The first pic is the order as I took the assembly out of the body (the golf tee is pointed the wrong way in the pic) but the order is the same.

The second pic is how it's going to go back together. Note I moved the clip back to slot #2 from the top.

Also note there is no little spacer/washer to be found anywhere. So my question is how important is that part. If necessary. I can try and make something that'll work. I need to know how thick it is supposed to be.

Is there a work around if that little spacer/washer is not there. What does that little spacer/washer do anyway?

Took the carbs off and disassembled. Before I put these things back together and mounted, again, I want to make sure I got it right.

The first pic is the order as I took the assembly out of the body (the golf tee is pointed the wrong way in the pic) but the order is the same.

The second pic is how it's going to go back together. Note I moved the clip back to slot #2 from the top.

Also note there is no little spacer/washer to be found anywhere. So my question is how important is that part. If necessary. I can try and make something that'll work. I need to know how thick it is supposed to be.

Is there a work around if that little spacer/washer is not there. What does that little spacer/washer do anyway?

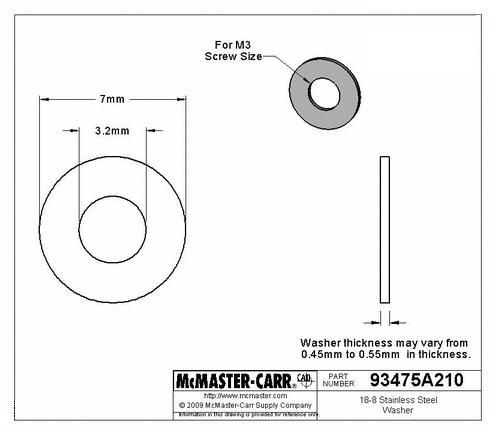

Yes, your 2nd pic is correct, spring on the needle and below the e-clip and spacer washers. I think the plain washer under the e-clip is there to keep the spring from catching on the e-clip open end, maybe possibly popping it off. Any small washer will probably do. The washer is about 1/2mm thick but the thickness isn't critical. It doesn't affect the needle height, just the amount of pre-load on the little spring.

Now you will see why you need to set the needle leaner with the larger mains. If you didn't, you would get bad break-up and stumbling under heavy throttle applications in the upper midrange, say in the 4 to 5K range. Most carbs need this change eventually if you increase the mains enough but the '78-'79 set usually needs it with any increase, even just one size. This is because the factory put a very large main jet in them, the largest of any 650 carb set. They leaned the midrange some to compensate with a smaller needle jet (Z-2) but the upper midrange is still right on the verge of being too rich. Any main jet size increase pushes it over that edge.

Now you will see why you need to set the needle leaner with the larger mains. If you didn't, you would get bad break-up and stumbling under heavy throttle applications in the upper midrange, say in the 4 to 5K range. Most carbs need this change eventually if you increase the mains enough but the '78-'79 set usually needs it with any increase, even just one size. This is because the factory put a very large main jet in them, the largest of any 650 carb set. They leaned the midrange some to compensate with a smaller needle jet (Z-2) but the upper midrange is still right on the verge of being too rich. Any main jet size increase pushes it over that edge.

Last edited:

Oddjob

adsgads

5twins, just to confirm, is the plain washer part of what you would see from the factory?

Yes, the 650 carb diagram doesn't show it but some others for different models with similar carbs do (XS400, XS750). And I've always found them in '78-'79 650 carbs. It makes sense that there should be a washer there to keep the spring from fouling the e-clip. Here's an XS400 carb diagram. The washer is part #60 but unfortunately, it's no longer available .....

https://www.partzilla.com/catalog/yamaha/motorcycle/1977/xs400d/carburetor

https://www.partzilla.com/catalog/yamaha/motorcycle/1977/xs400d/carburetor

Mickster

XS650 Enthusiast

Great explanation 5twins!

I made a spacer/washer out of an electrical connector. It is .030 thick. Not perfect in the ID (too big) or OD (too small) but enough to hold the spring in place and not bind on anything. Should be OK right?

I made a spacer/washer out of an electrical connector. It is .030 thick. Not perfect in the ID (too big) or OD (too small) but enough to hold the spring in place and not bind on anything. Should be OK right?

Yes, that should be fine. For shimming needles, I use regular M3 metric washers. If you're at a hardware store that sells metric fasteners, you might be able to pick up a couple. Their I.D. would fit the needle better .....

Similar threads

- Replies

- 22

- Views

- 484

- Replies

- 10

- Views

- 1K