-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mailman’s XS2 a full on restoration

- Thread starter Mailman

- Start date

Probably too late for this,

256-15351-00-00 - Drain plug (1970-1984)

The drain plug part number remained unchanged throughout production.

But, if I lay a screwdriver over the magnet of the later plug, the magnet is strong enough to let me lift it off the table. The early drain plug magnets fail this test, the magnets are weaker and release before I can lift the plugs off the table.

256-15351-00-00 - Drain plug (1970-1984)

The drain plug part number remained unchanged throughout production.

But, if I lay a screwdriver over the magnet of the later plug, the magnet is strong enough to let me lift it off the table. The early drain plug magnets fail this test, the magnets are weaker and release before I can lift the plugs off the table.

Like all of us the older you get the weaker you get.

Could it have been the engine heat cycles that de-magnetized the drain plug? Magnets don't like heat or impact. It de-polarizes the molecules. Maybe you could re-magnetize the drain plug using another (strong) magnet?the magnets are weaker

Dunno, guyz.

Just something else to fuss and agonize over...

Just something else to fuss and agonize over...

Dunno, guyz.

Just something else to fuss and agonize over...

Diggin the new avatar Steve! You old BBQ hunter you!

Hmmmm.....it’s almost time for thumpety-thumpety-thunpety.....

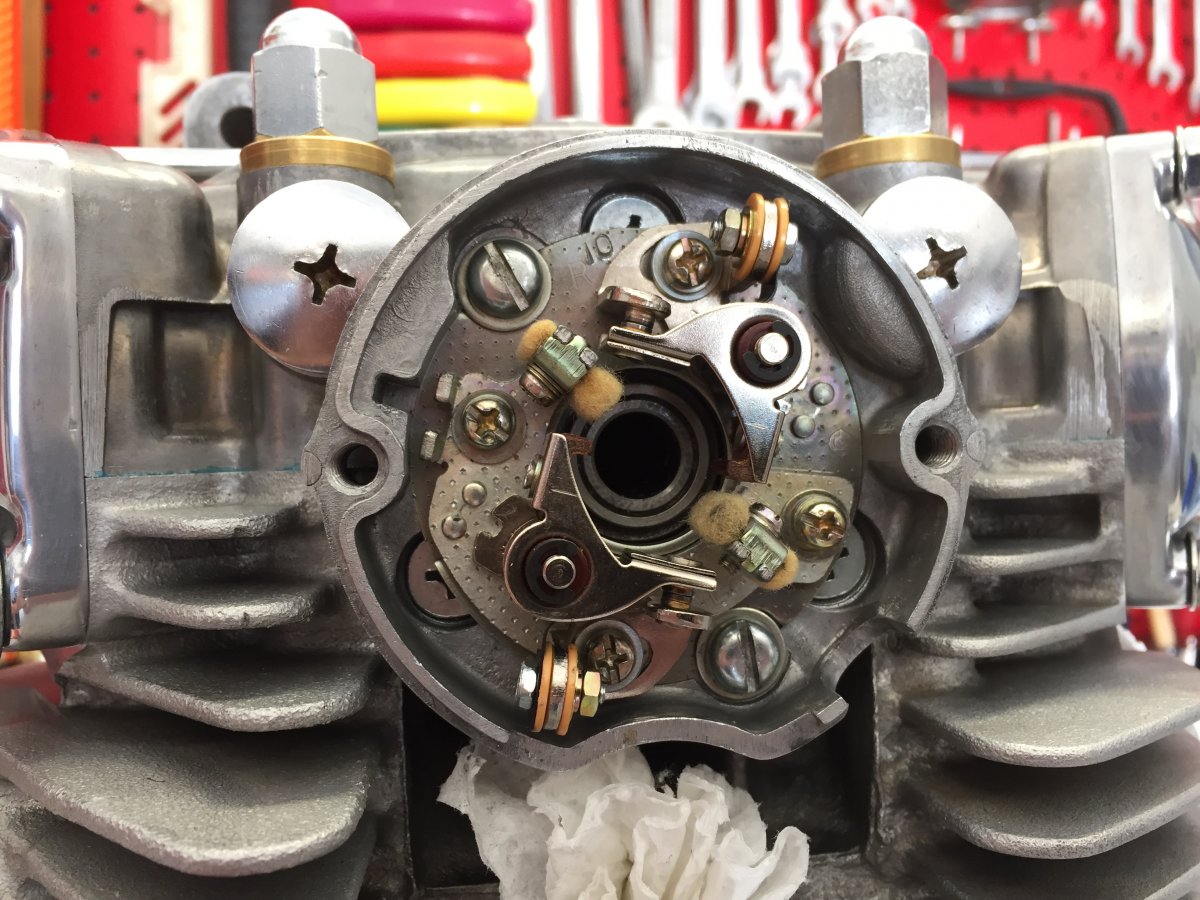

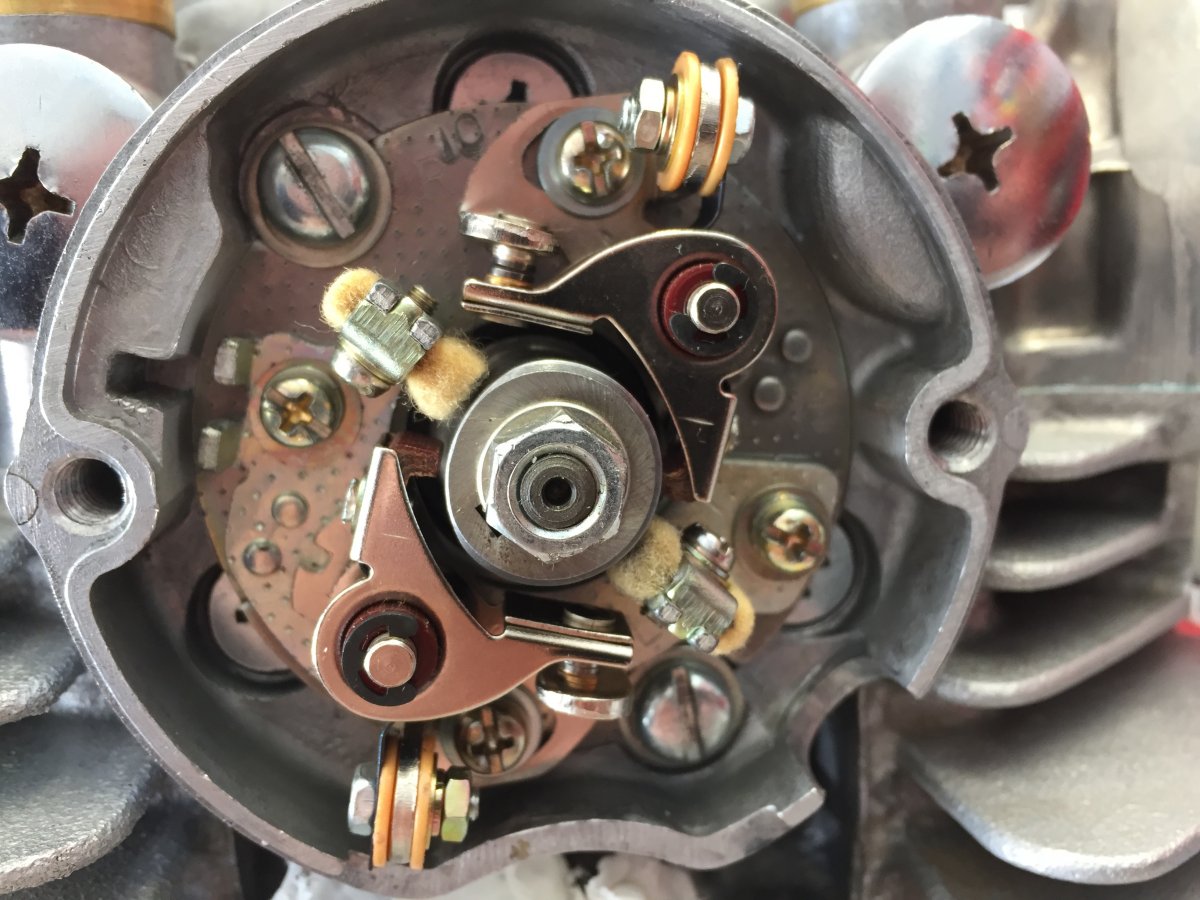

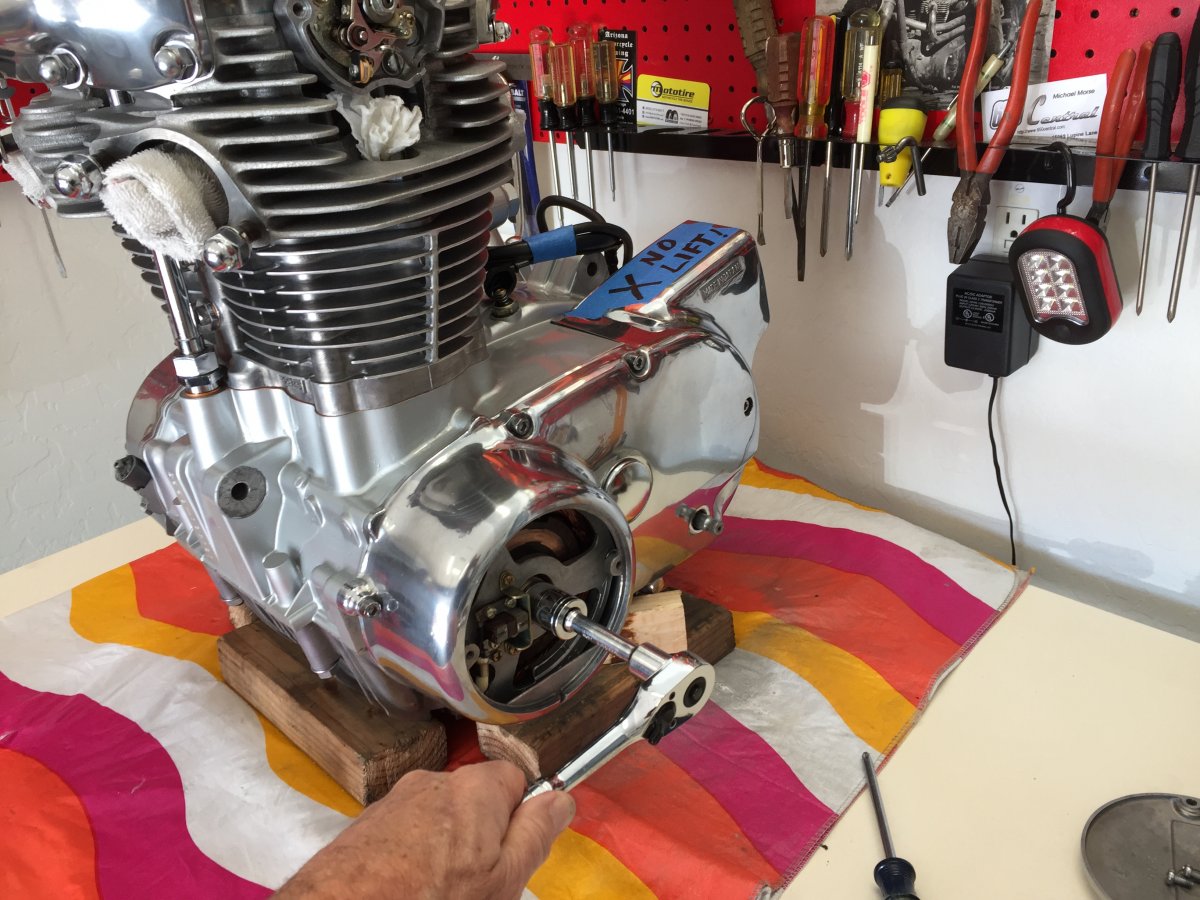

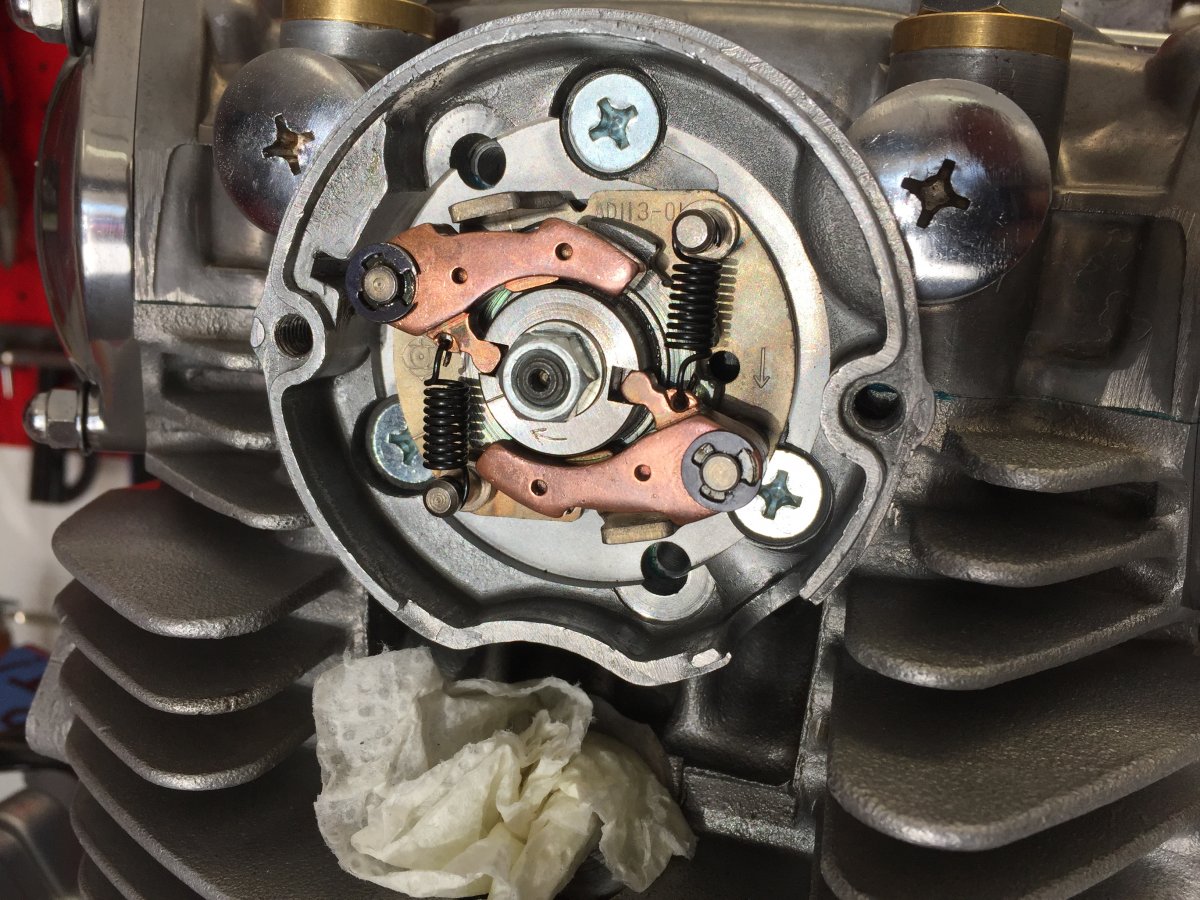

Today I worked on my points, advance rod installation and the mechanical advance unit. I have some questions I’ll save for the end.

Last week I broke all of the above components down and threw them in the ultrasonic cleaner to get the petrified crud off of everything. First thing I did was install brand new points, these are good quality Japanese parts.

Then I took the two felt oiling pads , that were hard as a rock with old oil, and threw them in some paint thinner to melt the solids.

Then cleaned them up in hot soapy water and dried them , then installed them.

Then installed the whole assembly in the motor.

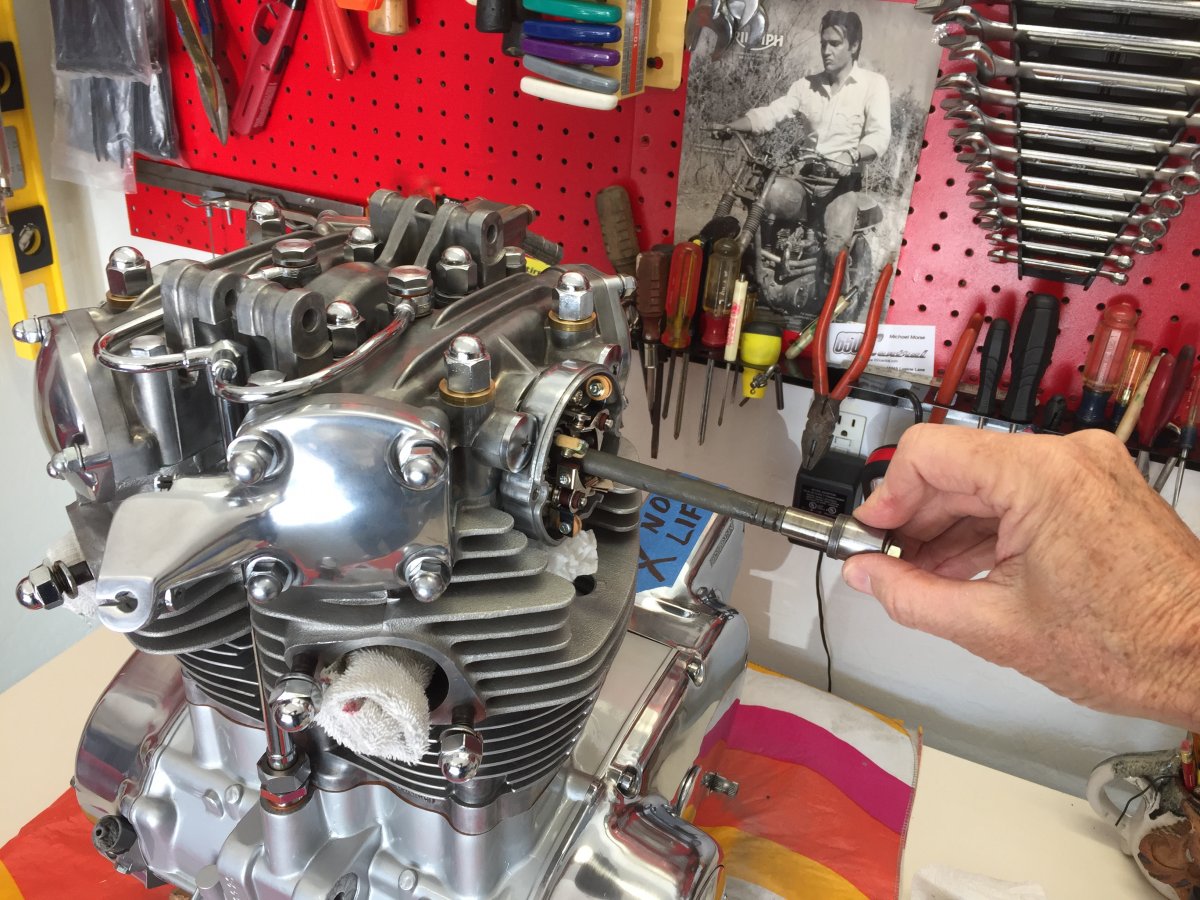

Then I focused on the advance rod, the points lobes were scrungy with ground in dirt and oil, so I shined it up with a dremel.

The bearings in the head have already been cleaned and greased, I smeared a light film on the advance rod and installed it.

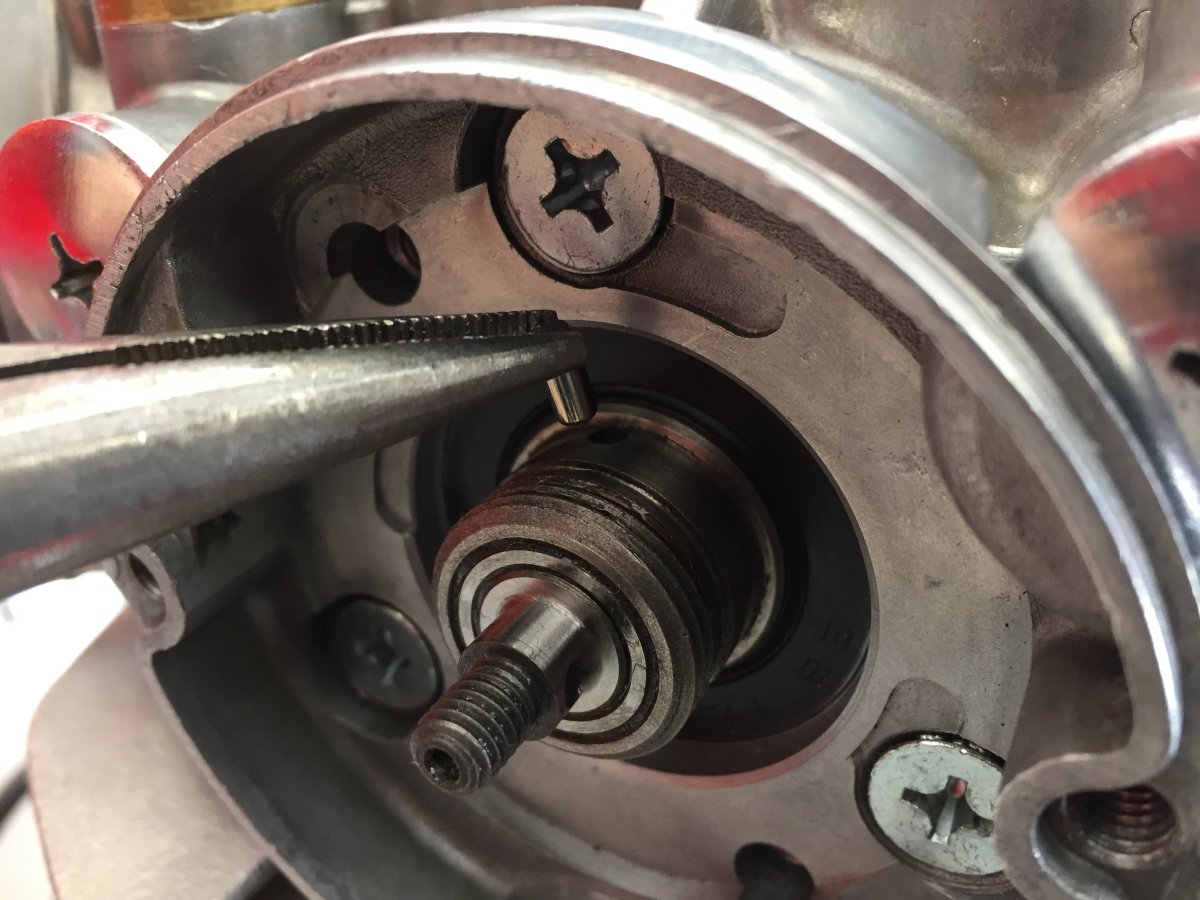

Now I turned my attention to the mechanical advance side. The first thing I did was rotate the crank until the hole for the locating pin on the advance rod was facing up and then installed the locating pin.

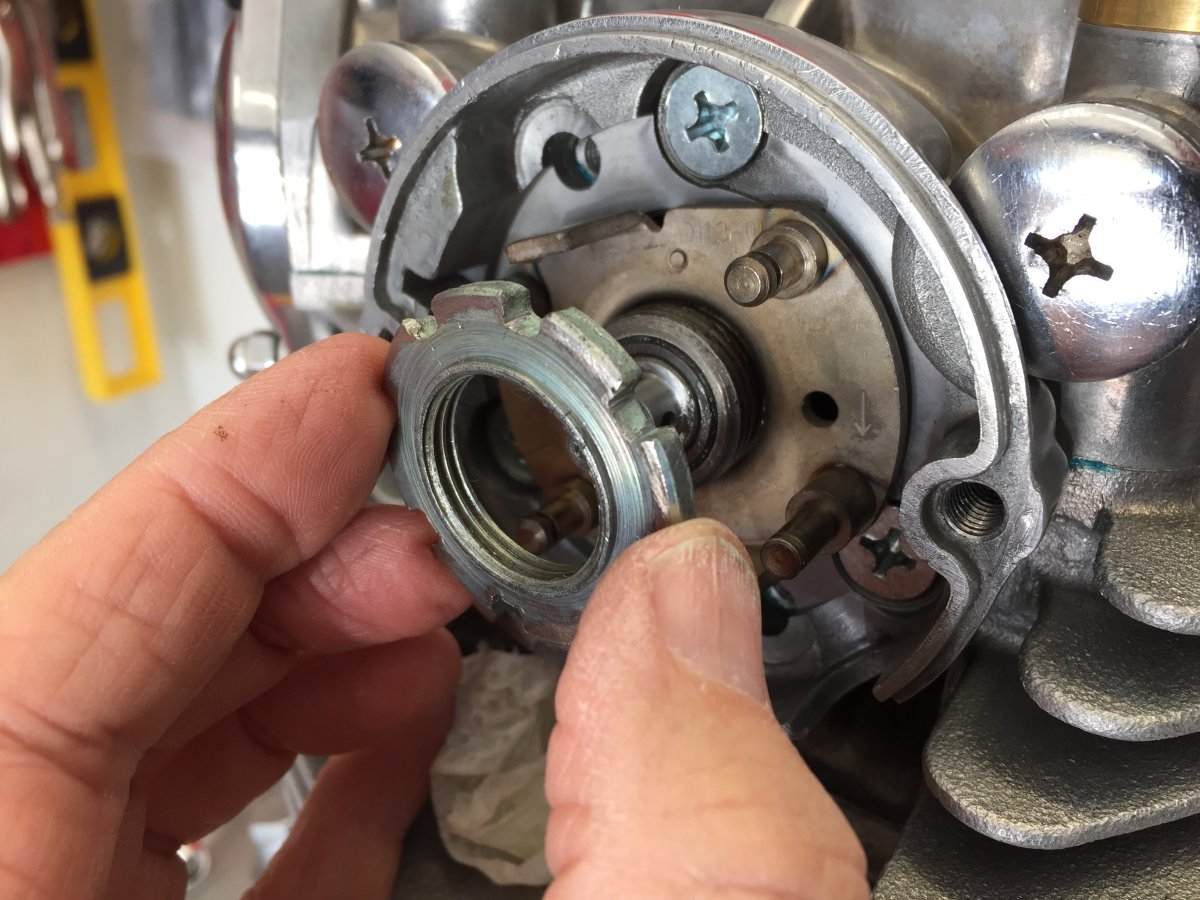

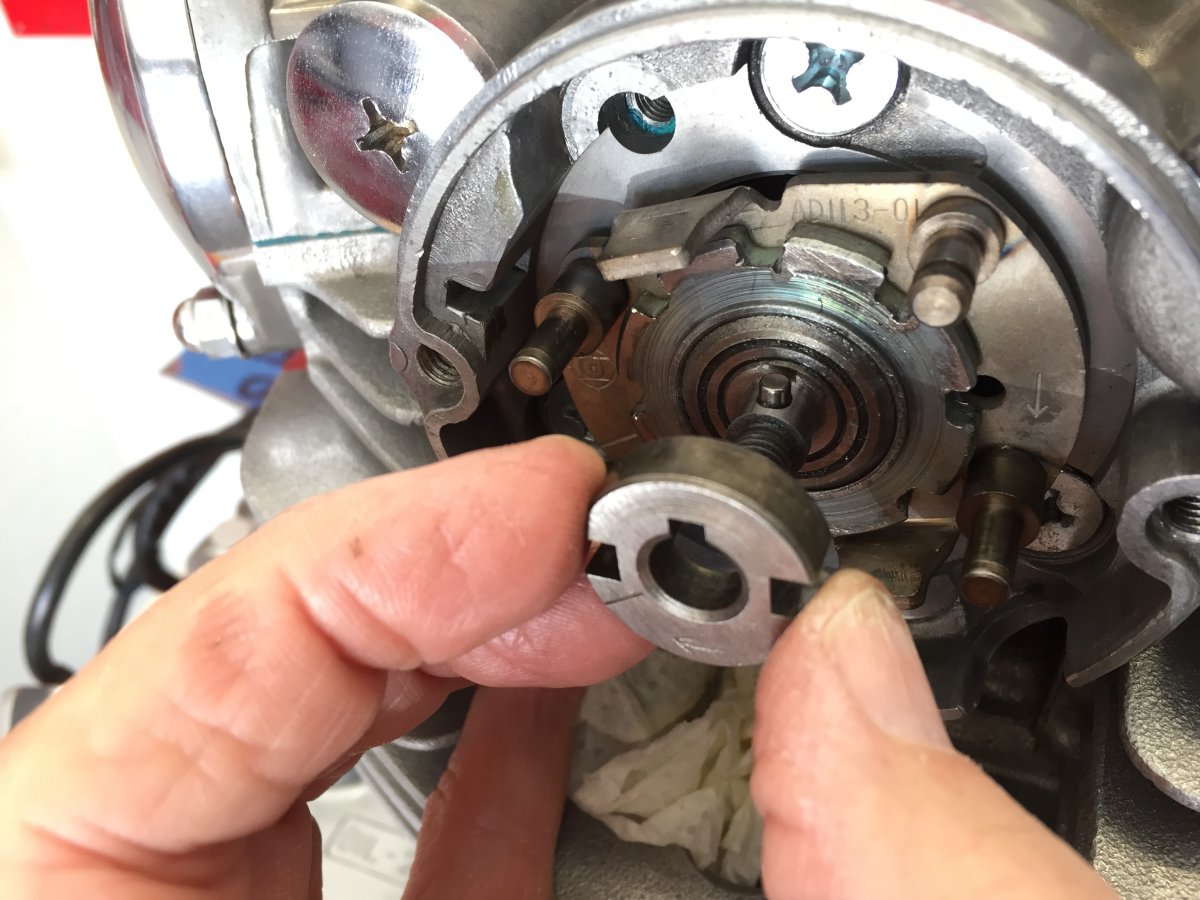

Next up, plate assembly and retaining nut.

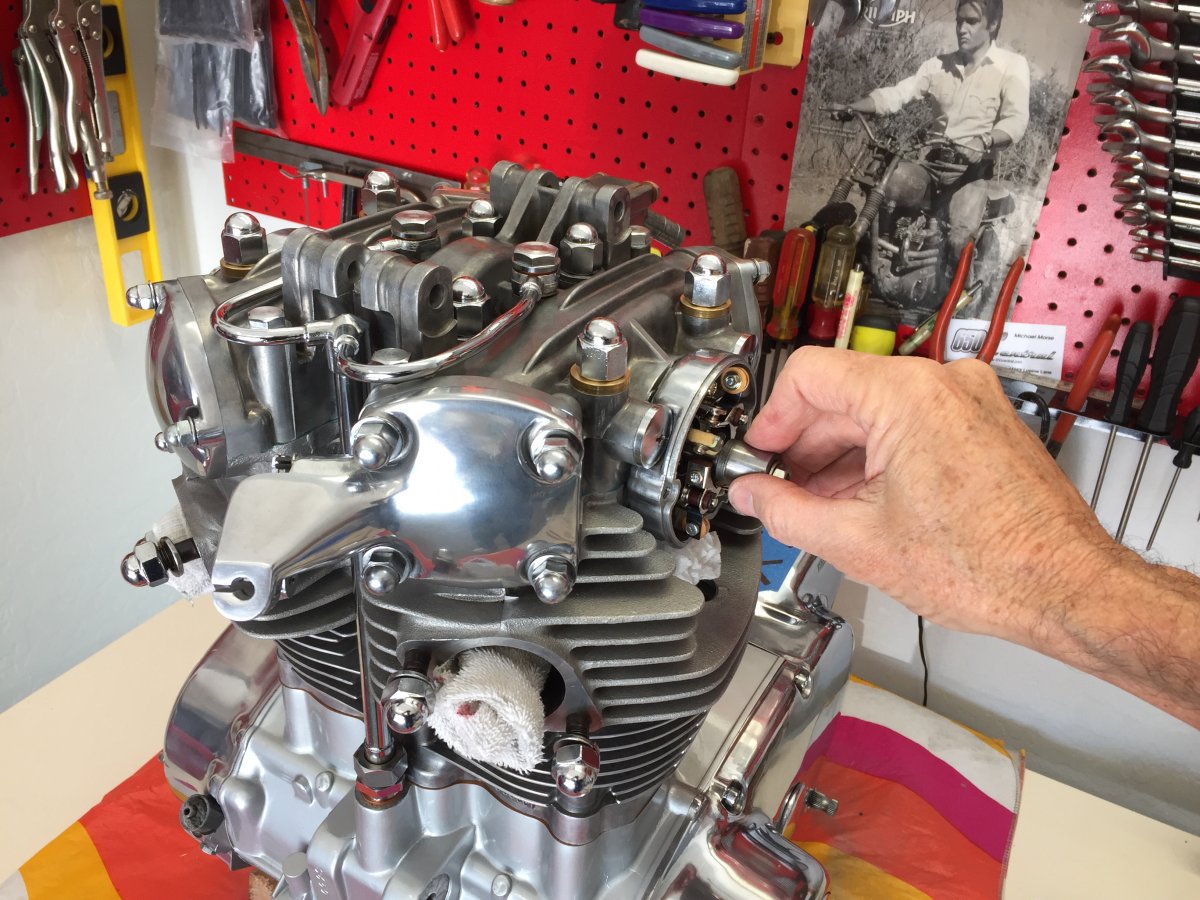

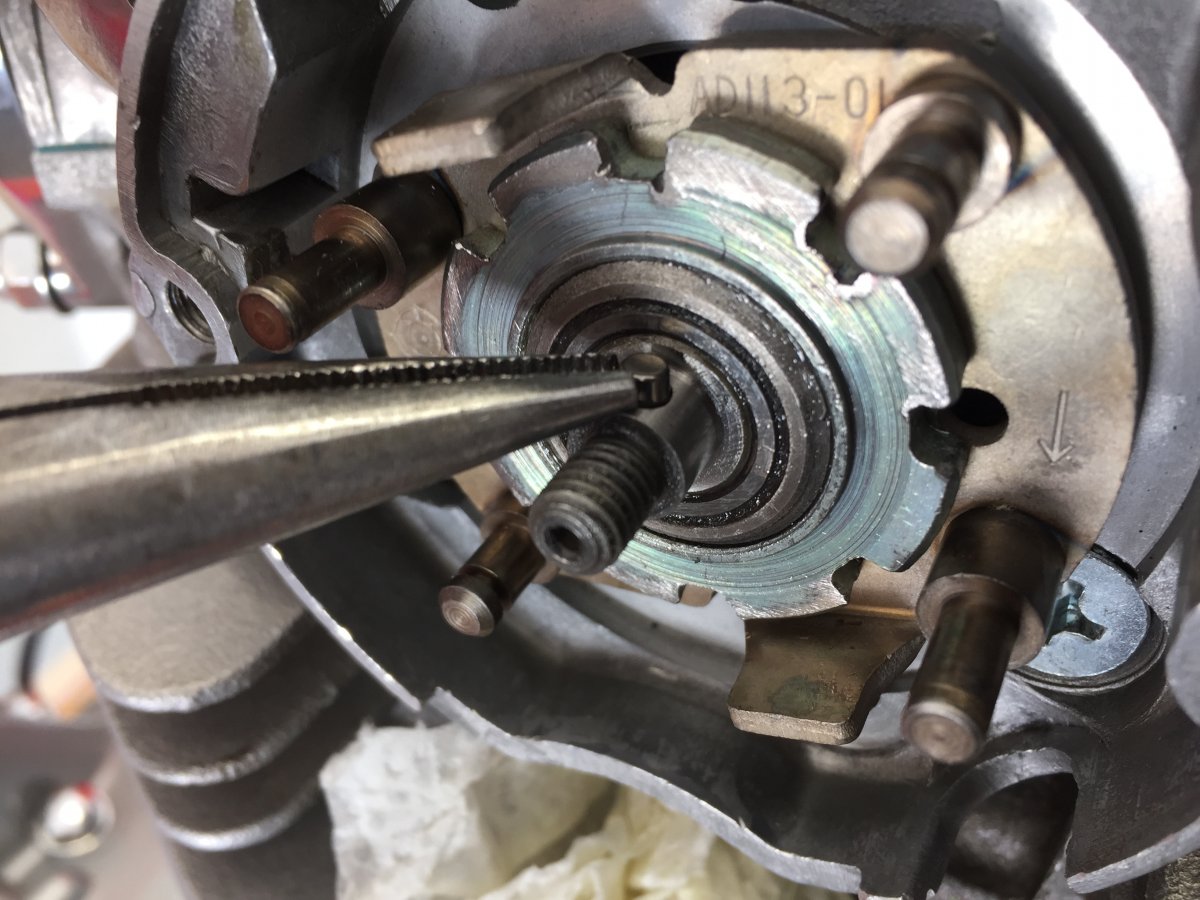

Then the last locating pin and the advance mechanism assembly.

I sure do have a lot of these paper thin shims. One under each of the weights and two on top, then the E Clip.

These E Clips need to be replaced before start up. They were the original parts and they don’t snap on tight.

So here’s my question. When I pull the weights away and let go, they don’t snap back. They kinda slowly return about halfway. Do you think maybe the new grease is just cold and stiff? Also maybe I didn’t help matters, I smeared a thin film of grease on the shaft the weights pivot on and also those thin shims. Could that be causing too much resistance? Or maybe the springs have weakened?

You know I have always had an aversion to points. The jury is still out for me as to whether I will keep them.

I’d really prefer a Pamco unit, I was going to try and force myself to learn to be good at adjusting these damn things!

I even bought a yellow meter at Robins encouragement a while back. It’s still in the original package! Haha!

I need to learn how to be more precise in adjusting points. I’ve forgotten so much over the years. How to set static timing and dwell. I’ve got to do some homework.

Ah well, till next time.

Bob

Last week I broke all of the above components down and threw them in the ultrasonic cleaner to get the petrified crud off of everything. First thing I did was install brand new points, these are good quality Japanese parts.

Then I took the two felt oiling pads , that were hard as a rock with old oil, and threw them in some paint thinner to melt the solids.

Then cleaned them up in hot soapy water and dried them , then installed them.

Then installed the whole assembly in the motor.

Then I focused on the advance rod, the points lobes were scrungy with ground in dirt and oil, so I shined it up with a dremel.

The bearings in the head have already been cleaned and greased, I smeared a light film on the advance rod and installed it.

Now I turned my attention to the mechanical advance side. The first thing I did was rotate the crank until the hole for the locating pin on the advance rod was facing up and then installed the locating pin.

Next up, plate assembly and retaining nut.

Then the last locating pin and the advance mechanism assembly.

I sure do have a lot of these paper thin shims. One under each of the weights and two on top, then the E Clip.

These E Clips need to be replaced before start up. They were the original parts and they don’t snap on tight.

So here’s my question. When I pull the weights away and let go, they don’t snap back. They kinda slowly return about halfway. Do you think maybe the new grease is just cold and stiff? Also maybe I didn’t help matters, I smeared a thin film of grease on the shaft the weights pivot on and also those thin shims. Could that be causing too much resistance? Or maybe the springs have weakened?

You know I have always had an aversion to points. The jury is still out for me as to whether I will keep them.

I’d really prefer a Pamco unit, I was going to try and force myself to learn to be good at adjusting these damn things!

I even bought a yellow meter at Robins encouragement a while back. It’s still in the original package! Haha!

I need to learn how to be more precise in adjusting points. I’ve forgotten so much over the years. How to set static timing and dwell. I’ve got to do some homework.

Ah well, till next time.

Bob

Attachments

I'd start by pulling the springs back off and working it by hand. That's should give you an idea on spring vs. drag. If it feels draggy... just start takin' it back apart till you find the source.So here’s my question. When I pull the weights away and let go, they don’t snap back. They kinda slowly return about halfway. Do you think maybe the new grease is just cold and stiff? Also maybe I didn’t help matters, I smeared a thin film of grease on the shaft the weights pivot on and also those thin shims. Could that be causing too much resistance? Or maybe the springs have weakened?

Btw... nice closeups.

Bob, your work is So clean . Such good detail! ! Your project pics are eye candy ! Thank you -R

I'd start by pulling the springs back off and working it by hand. That's should give you an idea on spring vs. drag. If it feels draggy... just start takin' it back apart till you find the source.

Btw... nice closeups.

Yeah that sounds right. I’ve got to take it apart to replace the clips anyways, and thanks, takes me longer to take photos, than do the work. Haha!

Yes, the sluggish advance return is probably due to all the fresh grease. It should "loosen" up quickly once you run it. I never found so many of those little shim washers on the weight posts, only one per post placed under the weight. Maybe that's causing the drag? A few more advance related things - I apply anti-seize to the end of the cam where the advance unit slips on. I've found them rusted and stuck on there. I realize rust isn't a big issue where you are but still, I hate mounting or assembling anything totally dry. I also wipe the backing plate down with oil. It's just raw steel so it can get rusty too. I don't soak it or anything, just a light wipe-down with a Q-tip dipped in motor oil. Anything extra will just fling off anyway once it's running and spinning. Speaking of which, you may find the excess grease on the advance rod bushings flinging out eventually. Just pull the covers off occasionally and wipe off any splatter.

Wow, I can't believe how nicely those points lubing pads cleaned up. They look like new. I think the manuals call for a few drops of oil on them but they do make actual points lubing grease, or at least they used to. It probably isn't easy to find these days, lol. I have a tube of Bosch Ft1v4 that was specifically speced for the old BMWs but I don't think you can get it anymore. I also have a little tube of Harley points grease. It's so old, it has the "AMF" label on it, lol.

Wow, I can't believe how nicely those points lubing pads cleaned up. They look like new. I think the manuals call for a few drops of oil on them but they do make actual points lubing grease, or at least they used to. It probably isn't easy to find these days, lol. I have a tube of Bosch Ft1v4 that was specifically speced for the old BMWs but I don't think you can get it anymore. I also have a little tube of Harley points grease. It's so old, it has the "AMF" label on it, lol.

I can't let the owner of the hotrod shop (where I'm working on "The Basketcase") see your 'guy in the suit', Bob. The work he does involves a clean-room (a HUGE ONE!) production floor! Next thing I know, he's gonna want me to put on one of those 'bunny' suits and pretty blue gloves!

Bob

Points are kind of cool to work with. But they do have their draw backs. On my XS2 I'm leaning towards a Pamco with e-advance. It will eliminate a lot of mechanical components that that need serviced at regular intervals. Just wish the e-advance units were on X-Mass sale.

Points are kind of cool to work with. But they do have their draw backs. On my XS2 I'm leaning towards a Pamco with e-advance. It will eliminate a lot of mechanical components that that need serviced at regular intervals. Just wish the e-advance units were on X-Mass sale.

I believe that my tube of Lubricam dates back to the late 70's or early 80's when I used the stuff on my Triumph Bonnevilles and VW bugs/Ghias:but they do make actual points lubing grease, or at least they used to

Yes, the sluggish advance return is probably due to all the fresh grease. It should "loosen" up quickly once you run it. I never found so many of those little shim washers on the weight posts, only one per post placed under the weight. Maybe that's causing the drag?

Thanks 5T,

I kinda suspect that it’s all the fresh grease, and it’s cold and stiff. When I have it apart to replace those E clips, I think I’m going to remove some of those shims. They don’t really seem necessary, perhaps they were stuck together from the factory?

A comment on the springs/advance if I may. If the advance is forcing the points cam follower UP the cam, it imposes a significant resistance to the springs. I find the "snap" varies with cam position. so don't get too worried til you check advance with a timing light.

A comment on the springs/advance if I may. If the advance is forcing the points cam follower UP the cam, it imposes a significant resistance to the springs. I find the "snap" varies with cam position. so don't get too worried til you check advance with a timing light.

Ok, I see what you’re saying. Thanks Gary!

Beautiful work, pics, and engine! Got room for a TX?