-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Electronic Ignition for xs650

- Thread starter paul650cn

- Start date

billy icon

test pilot,gunnie pig, and all around experiment

RC4man where are you? get yours??

Also Im pretty sure that Tytronics would send me three more at the discount, if people are interested,

the others where gone within 2 days lol

EDIT: the tytronics ingitions are 110.00 plus 20.00 shipping on ebay

so 130.00 to your door, definitely not inexpencive...

lest time I was able to pass them on at 75.00 dollors and 7.65 shipping.

that's about 50 dollars off, I assume that tytronics thought I was going to make money and that's why they where priced they way they where. ALSO note I belive they ebay one you will recive will not have the on board LED timing lights incorporated into the pickups, who knows that may turn out to be a disadvantage... still to be seen

Also Im pretty sure that Tytronics would send me three more at the discount, if people are interested,

the others where gone within 2 days lol

EDIT: the tytronics ingitions are 110.00 plus 20.00 shipping on ebay

so 130.00 to your door, definitely not inexpencive...

lest time I was able to pass them on at 75.00 dollors and 7.65 shipping.

that's about 50 dollars off, I assume that tytronics thought I was going to make money and that's why they where priced they way they where. ALSO note I belive they ebay one you will recive will not have the on board LED timing lights incorporated into the pickups, who knows that may turn out to be a disadvantage... still to be seen

Last edited:

billy icon

test pilot,gunnie pig, and all around experiment

is there a rule againt multiple posts??

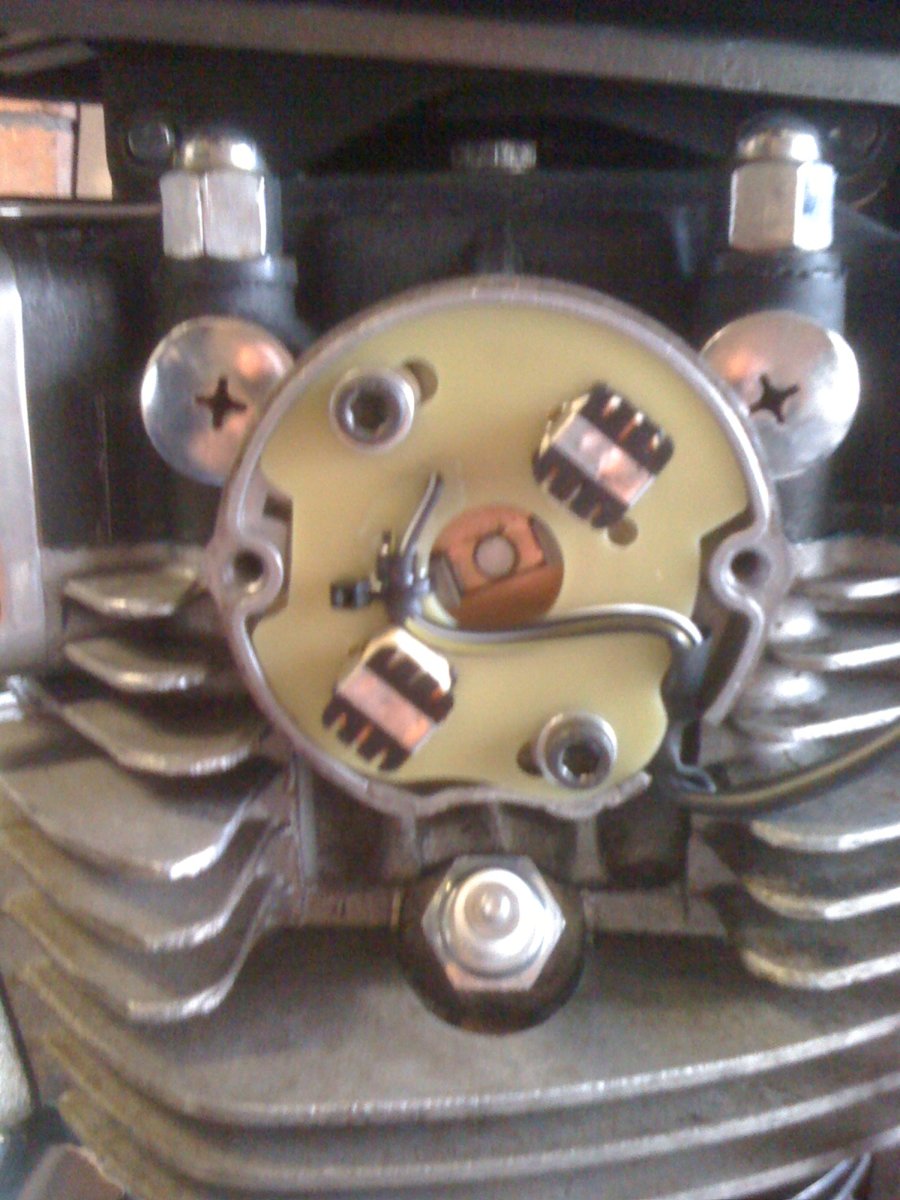

I just wanted to further my answer about "pennies" worth of parts, here is a photo of the boyer plate , now I have the boyer system on two triumphs, and I have purchased a third for an xs 650 build (to come shorty stay tuned) anyways I have never had a boyer fail, and I think they are a quality product, BUT look how simple the part is, the windings in the sensors are just bare, (sure there is sealer on the wire that is wound in the windings of the sensors and a thin piece of "KAPTON" tape wraped around (pickups) but this is easy to Back engineer in your own shop and reproduce, Im not sure whats inside the trtronics and the second photo is the spinning double headed magnetic triger, again a part I or you could bang out on a Mill/lathe.. so back to my original point was if one of us is a electrical guy and one of us a mchinest, and so on we would be able to produce a product together "open source" as in all the imfo is free for anyone use or improve upon, now the real question is whats in the magic blue or red box that retards the timing, YES thats right you set the timing at full advance, and it retards the timing at idle and then it advances it for the rpm range, SIDE NOTE , boyer advertises at least for the vintage triumphs that the advance curve is more suited to todays gassoline, and in my mind that means its not as agressive since super used to be 98 octane and a pretty pink color.. hehe, but anyways in my mind that tells me that the factory ignition curve of the weighted avance unit would be better for a performance engine where you might be purchasing better gas or octane booster for...

and finnaly an interesting video about boyers

I just wanted to further my answer about "pennies" worth of parts, here is a photo of the boyer plate , now I have the boyer system on two triumphs, and I have purchased a third for an xs 650 build (to come shorty stay tuned) anyways I have never had a boyer fail, and I think they are a quality product, BUT look how simple the part is, the windings in the sensors are just bare, (sure there is sealer on the wire that is wound in the windings of the sensors and a thin piece of "KAPTON" tape wraped around (pickups) but this is easy to Back engineer in your own shop and reproduce, Im not sure whats inside the trtronics and the second photo is the spinning double headed magnetic triger, again a part I or you could bang out on a Mill/lathe.. so back to my original point was if one of us is a electrical guy and one of us a mchinest, and so on we would be able to produce a product together "open source" as in all the imfo is free for anyone use or improve upon, now the real question is whats in the magic blue or red box that retards the timing, YES thats right you set the timing at full advance, and it retards the timing at idle and then it advances it for the rpm range, SIDE NOTE , boyer advertises at least for the vintage triumphs that the advance curve is more suited to todays gassoline, and in my mind that means its not as agressive since super used to be 98 octane and a pretty pink color.. hehe, but anyways in my mind that tells me that the factory ignition curve of the weighted avance unit would be better for a performance engine where you might be purchasing better gas or octane booster for...

and finnaly an interesting video about boyers

Attachments

Last edited:

Interesting comparo between the Tytronic and Boyer.

Boyer uses a G-10, laminated glass base plate, it's a good electrical insulator. If the Tytronic pickups are well potted and insulated it's fine to have a metal base.

They appear to be so, with their integral covers.

The Boyer appears to fire both coils together, not sure if that is the intended set up or this person just has them wired that way. Doesn't look like the pickups are individually adjustable for side so perhaps they have to be run that way. That being the case not sure why there are two trigger coils. Perhaps I'm missing something.

What does the Boyer box do and why is there not a similar item for the Tytronic?

The Tytronic looks to fire each coil individually, one magnet on the rotor rather than the two magnets the Boyer rotor has. If this is just a points replacement plate with hall effect triggers then perhaps a related box is not necessary.

As another said earlier, condensers are just to prevent point arcing so in this case they would be eliminated.

I assume the rotor relies on the existing mechanical advance as the stock lobed points rotor.

It'll be months before I'm ready for the install so I'll be anxiously watching this thread for the installation details

I received the unit in mail yesterday and haven't done more than open the box but the Chinglish translation pictured above leaves much to be desired.

Boyer uses a G-10, laminated glass base plate, it's a good electrical insulator. If the Tytronic pickups are well potted and insulated it's fine to have a metal base.

They appear to be so, with their integral covers.

The Boyer appears to fire both coils together, not sure if that is the intended set up or this person just has them wired that way. Doesn't look like the pickups are individually adjustable for side so perhaps they have to be run that way. That being the case not sure why there are two trigger coils. Perhaps I'm missing something.

What does the Boyer box do and why is there not a similar item for the Tytronic?

The Tytronic looks to fire each coil individually, one magnet on the rotor rather than the two magnets the Boyer rotor has. If this is just a points replacement plate with hall effect triggers then perhaps a related box is not necessary.

As another said earlier, condensers are just to prevent point arcing so in this case they would be eliminated.

I assume the rotor relies on the existing mechanical advance as the stock lobed points rotor.

It'll be months before I'm ready for the install so I'll be anxiously watching this thread for the installation details

I received the unit in mail yesterday and haven't done more than open the box but the Chinglish translation pictured above leaves much to be desired.

In the instructions line 7 says connect orange and grey wires. I assume that means to the coils, like in the points system. orange to the left coil, grey to right coil.

The instructions are a bit incomplete. Language barriers I guess.

Leo

The instructions are a bit incomplete. Language barriers I guess.

Leo

The Tytronic ignition. I rode to the diner for breakfast this morning, 45F, it was a glorious ride. I took the Tytronic ignition with me so we could spend some time alone.

There are two magnets on the rotor. Measuring with a set of dividers the two magnets are spaced 1/3 of the diameter of the pie/rotor apart. That makes the area of the rotor between the magnets 120 degrees of the whole pie. So, with the dwell happening between the magnets, that makes the dwell 120 degrees at the camshaft, 240 degrees at the crankshaft. (Edited for lack of 4 stroke engine theory) Those pickups are some smart little guys if they can tell the difference between one magnet and the other magnet.

I'm thinking about pie for lunch.

Scott

There are two magnets on the rotor. Measuring with a set of dividers the two magnets are spaced 1/3 of the diameter of the pie/rotor apart. That makes the area of the rotor between the magnets 120 degrees of the whole pie. So, with the dwell happening between the magnets, that makes the dwell 120 degrees at the camshaft, 240 degrees at the crankshaft. (Edited for lack of 4 stroke engine theory) Those pickups are some smart little guys if they can tell the difference between one magnet and the other magnet.

I'm thinking about pie for lunch.

Scott

Last edited:

Opposite poles on the magnets. My coil winder counter can tell the difference too. If I flip the magnet, it counts twice for every revolution.Those pickups are some smart little guys if they can tell the difference between one magnet and the other magnet.

120° at the cam is 240° at the crank.that makes the dwell 120 degrees at the camshaft, 60 degrees at the crankshaft.

Dwell spec for the points models is 93°± 5°, or 88°- 98°, at the cam. Dwell measures the time the points are closed, "dwelling" in the closed position. During this time, the coil is charging itself up for the next spark. I suppose a little longer dwell time wouldn't hurt anything, as long as the ignition could still be made to fire at the right time. Who knows, maybe it would even make for a bit better (stronger) spark being that the coil has built up a bigger charge.

120 240 either way = 30% dwell

360 720

360 720

sure 33.333-% Was just saying it ~matches what Tytronics is saying it does, and IMHO that's fine/plenty of dwell for the 7000 RPM redline.

I've seen some arguments that dwell should increase at higher RPMs because coil soak time between spark events declines as RPM goes up.

I've seen some arguments that dwell should increase at higher RPMs because coil soak time between spark events declines as RPM goes up.

Last edited:

Hmmmm....this is sounding pretty good actually.

I wonder when his e-advancer system is coming out.....

I wonder when his e-advancer system is coming out.....

OK guys, this deserves a more accurate re-measure, something better than bouncing my dividers around the rotor.

Measure the diameter of the rotor.OK guys, this deserves a more accurate re-measure, something better than bouncing my dividers around the rotor.

Example: Circumference is 3".... distance 'tween magnets is 1". Dwell is 33.3%

Last edited:

Area

Last edited:

Hmmmm....this is sounding pretty good actually.

I wonder when his e-advancer system is coming out.....

Yeah, I'm as excited as Joe Namath selling Medicare coverage.

If the Tytronic can gain a good reputation, considering the installation instructions and the diagram in that Honda install video, I see a lot of kill switches will be bypassed unknowingly and unnecessarily.

Scott

Scott

Last edited:

Yeah, I'm as excited as Joe Namath selling Medicare coverage.

yup - or Tom Selleck peddling reverse mortgages.

.....like he needs one....

billy icon

test pilot,gunnie pig, and all around experiment

I have a extra boyer RED box in my parts bin,(the blue and red boxes are different... if someone here is a electronics wiz I would be willing to send it to them for reverse engineering ,....or maybe I will take it apart myself with the help of the collective and see if we all cant figure out what kinda pixie dust and unicorn blood there putting in these..

think about this guys, what if we where to create an E advancer to use with the tytronics plate, how cool would that be, and I also know that some high tech boxes for bikes like Harleys or sportbikes (power commander) have adjustable timing curves, again like I said before the parts inside these magic boxes are pennies, almost all electronic stuff is pennies, its the knowledge of how to make something out of the parts that is expensive, gary I asked before but I didn't see the answer are you going to use a pamco electronic advancer in conjunction with this tyroniccs plate?

think about this guys, what if we where to create an E advancer to use with the tytronics plate, how cool would that be, and I also know that some high tech boxes for bikes like Harleys or sportbikes (power commander) have adjustable timing curves, again like I said before the parts inside these magic boxes are pennies, almost all electronic stuff is pennies, its the knowledge of how to make something out of the parts that is expensive, gary I asked before but I didn't see the answer are you going to use a pamco electronic advancer in conjunction with this tyroniccs plate?

Similar threads

- Replies

- 10

- Views

- 503

- Replies

- 4

- Views

- 773