I've long pondered ways to improve our beloved XS650 but sadly don't have the tools necessary to do these things myself. Thus the reason I post my ideas here.

Timing chains have almost completely disappeared from modern automobiles but still remain common on motorcycles. But could that be about to change? And could it be that someone who reads this forum becomes a pioneer in making that change take place?

A company called Mitsuboshi has developed a timing belt that runs in oil.

From their website: https://www.mitsuboshi.com/english/prime-stars/timing.html

"Benefits of using Timing Belt in Oil

"Now, performance enthusiasts may have some experience with “wet belt” timing systems as an upgrade for the small-block Chevy, but these “new” BIO systems are OEM designs, used for oil pump drives as well as for camshaft timing drives. As a performance upgrade, belt drives have a couple of advantages. Since a timing belt is lighter than a chain, and it can absorb and isolate crankshaft harmonics from the valvetrain, a belt is quieter and doesn’t rob additional power from the engine.

“Fuel efficiency,” “reduced emissions,” “noise, vibration, harshness” (NVH) and “compact design” are all popular catch-phrases in the auto industry, and these also are the driving forces behind belt-in-oil technology. By designing a light, quiet and compact belt drive, manufacturers hope to increase fuel efficiency while reducing emissions and NVH, and package it all into ever-smaller engine designs. Belt-in-oil manufacturers claim that “wet belts” offer up to 30 percent reductions in friction loss as compared to chains or dry belts. This reduces emissions and can increase fuel economy by a little more than 1 percent.

Due to the improved materials used in the BIO drives, these belts are more temperature-resistant, less prone to stretching than conventional dry belts and have a life expectancy of up to 150,000 miles. The first automotive BIO system was introduced in 2008, hidden inside the European-market 1.8L Ford diesel. Volkswagen soon followed with its EA211 and EA288 engine families of three- and four-cylinder gas and diesel variants. Here in the United States, belt-in-oil applications are a bit more limited, in the form of the 1.0L Ford EcoBoost gasoline engine, and (if you like to think outside the box), Honda offers the GC and GCV series of small engines featuring an internal oil-bath timing belt." https://www.counterman.com/belt-in-oil-timing-drives/

Did you catch that, "a life expectancy of up to 150,000 miles." Did you?

And just think of all the different kinds of old overhead cam motorcycle engines that are out there just waiting for something like this.

Update: Gates, BorgWarner, and Dayco are also making what they call "wet belts".

Timing chains have almost completely disappeared from modern automobiles but still remain common on motorcycles. But could that be about to change? And could it be that someone who reads this forum becomes a pioneer in making that change take place?

A company called Mitsuboshi has developed a timing belt that runs in oil.

From their website: https://www.mitsuboshi.com/english/prime-stars/timing.html

"Benefits of using Timing Belt in Oil

- While a guide is necessary for a chain drive, it is unnecessary for Timing Belt in Oil. A guide is no longer needed for oil timing drive system, which makes a light weight and low noise engine.

- Because it has excellent transmission efficiency compared to metal chains, it contributes significantly to improved fuel efficiency and decreases energy loss.

- Because it can be used in the same way as a metal chain inside the engine block, without greatly changing the engine layout, it is possible to replace with the belt from the chain."

"Now, performance enthusiasts may have some experience with “wet belt” timing systems as an upgrade for the small-block Chevy, but these “new” BIO systems are OEM designs, used for oil pump drives as well as for camshaft timing drives. As a performance upgrade, belt drives have a couple of advantages. Since a timing belt is lighter than a chain, and it can absorb and isolate crankshaft harmonics from the valvetrain, a belt is quieter and doesn’t rob additional power from the engine.

“Fuel efficiency,” “reduced emissions,” “noise, vibration, harshness” (NVH) and “compact design” are all popular catch-phrases in the auto industry, and these also are the driving forces behind belt-in-oil technology. By designing a light, quiet and compact belt drive, manufacturers hope to increase fuel efficiency while reducing emissions and NVH, and package it all into ever-smaller engine designs. Belt-in-oil manufacturers claim that “wet belts” offer up to 30 percent reductions in friction loss as compared to chains or dry belts. This reduces emissions and can increase fuel economy by a little more than 1 percent.

Due to the improved materials used in the BIO drives, these belts are more temperature-resistant, less prone to stretching than conventional dry belts and have a life expectancy of up to 150,000 miles. The first automotive BIO system was introduced in 2008, hidden inside the European-market 1.8L Ford diesel. Volkswagen soon followed with its EA211 and EA288 engine families of three- and four-cylinder gas and diesel variants. Here in the United States, belt-in-oil applications are a bit more limited, in the form of the 1.0L Ford EcoBoost gasoline engine, and (if you like to think outside the box), Honda offers the GC and GCV series of small engines featuring an internal oil-bath timing belt." https://www.counterman.com/belt-in-oil-timing-drives/

Did you catch that, "a life expectancy of up to 150,000 miles." Did you?

And just think of all the different kinds of old overhead cam motorcycle engines that are out there just waiting for something like this.

Update: Gates, BorgWarner, and Dayco are also making what they call "wet belts".

Last edited:

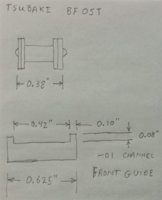

Chain manufacturers spec chain wear limits as 3% elongation from spec. Timing chain "failure" is virtually unheard of in the XS650. AFAIK the biggest enemy to XS timing chains (and trashing the front guide) is ham handed over tightening by backyard "mechanics".

Chain manufacturers spec chain wear limits as 3% elongation from spec. Timing chain "failure" is virtually unheard of in the XS650. AFAIK the biggest enemy to XS timing chains (and trashing the front guide) is ham handed over tightening by backyard "mechanics".