Something went smoothly for a change as I got the crankcase opened pretty easily, heat and a rubber mallet.

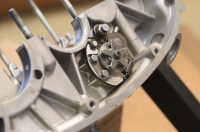

Everything looks pretty much as it should. The gears seem free of glass bead media, but I was going to remove the 4 bearings to clean with kerosene or brake cleaner.

the case bearing seats have a few scratches but no gouges.

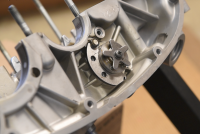

When I opened the case I noticed that this circlip wasn't seated properly, hoping it doesn't mean anything?

I'm not removing the shift drum assembly. The shifting forks don't show much wear.

The crankshaft seems to having gotten the worst of the glass bead. the bearings appear a little caked. They seem to move freely on the shaft so I'm going to try to flush them out on the unit. The connecting rods don't appear to have more than 2mm play.

These 2 little extra oil passages caught me off gaurd when I ejected brake clean into the oil passage it shot out and I was sure I had cracks in the crankcase!

I was going to add a 5th OD gear but after reading several posts it doesn't seem worth the trouble. Unfortunately I hadn't removed the 4 bolts holding the cam chain guide while the engine was upright and now they won't budge, separating the crankcase was easier. Now i'm going to clean everything and reassemble.