RonXS

XS650 Addict

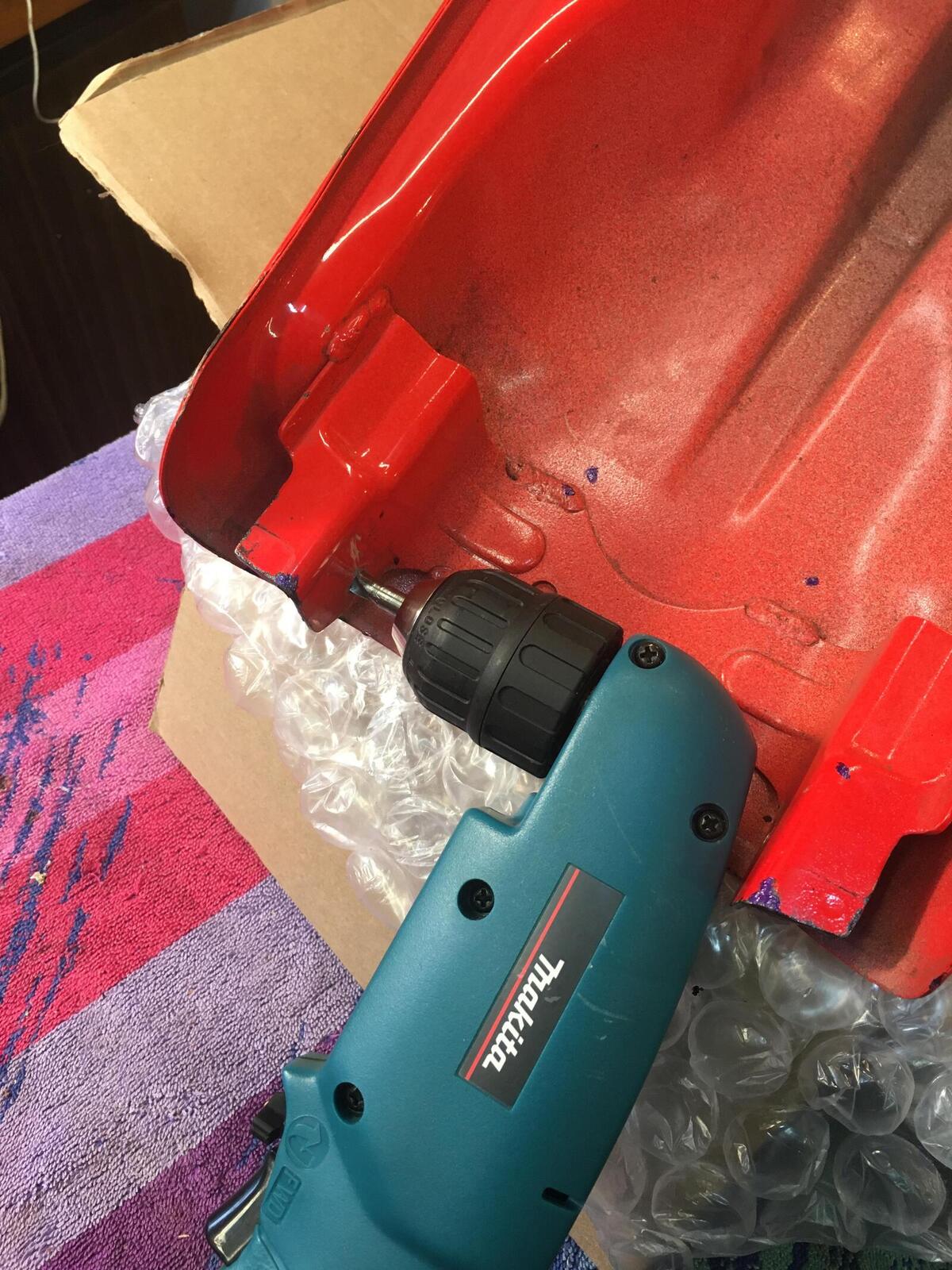

Tank mounted securely... Will paint the bracket when I paint the frame. There's enough room for something... just don't know what.

Couldn't have drilled the holes without this Mikita I picked up on a whim at 'Habitat For Humanity'. That and a few resharpened broken drill bits...

Couldn't have drilled the holes without this Mikita I picked up on a whim at 'Habitat For Humanity'. That and a few resharpened broken drill bits...

Last edited: