-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it my turn? Anything to do with lathes, mills and other shop tools

SEd27

XS650 Addict

Have a couple noob question for you guys with Lathes, as I am looking to purchase one.

I’ve got limited space (12’ x 12’ shop). What size should I be focusing my search on? Only looking to do motorcycle related projects.

What can I reasonably looking to budget to get started? Would be looking for an older machine.

Everything in my surrounding area seems to fall in the following ranges - $1000-$1500+ for non running/ missing parts: $2000-$3000+ Older running units.

All prices in Canadian dollars

I’ve got limited space (12’ x 12’ shop). What size should I be focusing my search on? Only looking to do motorcycle related projects.

What can I reasonably looking to budget to get started? Would be looking for an older machine.

Everything in my surrounding area seems to fall in the following ranges - $1000-$1500+ for non running/ missing parts: $2000-$3000+ Older running units.

All prices in Canadian dollars

Last edited:

Many people say to buy the biggest you can afford. I say buy the biggest you can move. If you have the right equipment at home you can move big lathes. My baby lathe can be picked up and moved about quite easily by me but it has a maximum working diameter of about 3.5". That is fine for me but sometimes I wish I could go much bigger. For example I had an unevenly worn disk brake rotor and I would love to have put it in a lathe with a grinder attached. Instead I had to bolt it to the bench and grind carefully by hand with an oil stone for 5 hours. If you know what sort of projects you will work on then you can match them to a lathe size. If you are not sure but have the workshop space then do as Ratranger suggested above. Also, some lathes have a small section of the bed near the chuck that can be removed to allow even large items to be worked on. Check your electrics to see what horsepower motor you can run - approximately 750 Watt is 1 Hp. If you buy one and it proves to be too small you can always sell it and buy another. The resale prices on lathes is excellent so you do not lose much. I have done several repair jobs that saved we more than the lathe cost e.g. I repaired a Hitachi carburetor 2 years back because parts were not available. Buying replacements carbs have cost more than my lathe cost.

Last edited:

SEd27

XS650 Addict

Many people say to buy the biggest you can afford. I say buy the biggest you can move. If you have a right equipment at had you can move big lathes. My baby lathe can be picked up and moved about quite easily by me but it has a maximum working diameter of about 3.5". That is fine for me but sometimes I wish I could go much bigger. For example I had an unevenly worn disk brake rotor and I would love to have put it in a lathe with a grinder attached. Instead I had to bolt it to the bench and grind carefully by hand with an oil stone for 5 hours. If you know what sort of projects you will work on then you can match them to a lathe size. If you are not sure but have the workshop space then do as Ratranger suggested above. Also, some lathes have a small section of the bed near the chuck that can be removed to allow even large items to be worked on. Check you electrics to see what horsepower motor you can run - approximately 750 Watt is 1 Hp. If you buy one and it proves to be too small you can always sell it and buy another. The resale prices on lathes is excellent so you do not lose much. I have done several repair jobs that saved we more than the lathe cost e.g. I repaired a Hitachi carburetor 2 years back because parts were not available. Buying replacements carbs have cost more than my lathe cost.

Ratranger and Paul Sutton,

Thanks for the input. That is just what I was looking for.

SEd27

XS650 Addict

One more question for the experienced...does it make sense to try and find a milling machine instead?

Used lathes seem to be more plentiful, but there is an appeal to the smaller footprint the mill provides.

Used lathes seem to be more plentiful, but there is an appeal to the smaller footprint the mill provides.

Both can do things the other can't. Mill is very handy for some jobs, but lathe gets a big workout on bikes. Spacers, adapters, pegs, etc all on lathe.

If you can get a milling adapter you can do some milling on the lathe. The benchtop mills can do more than a milling adapter on a lathe, but are very limited compared to a knee mill.

I would get a lathe first, easier to learn, less extras needed to get the best out of it. A couple HSS tool blanks, a bench grinder, and some time will get you going.

To really get the full use out of a mill there are lots of extras needed. Vise, collets, end mills, drill chuck, parallels, and that's basics. Depending on what you want to do add a rotary table, indexer, dividing head, fly cutter, angle plate, and many more.

If you can get a milling adapter you can do some milling on the lathe. The benchtop mills can do more than a milling adapter on a lathe, but are very limited compared to a knee mill.

I would get a lathe first, easier to learn, less extras needed to get the best out of it. A couple HSS tool blanks, a bench grinder, and some time will get you going.

To really get the full use out of a mill there are lots of extras needed. Vise, collets, end mills, drill chuck, parallels, and that's basics. Depending on what you want to do add a rotary table, indexer, dividing head, fly cutter, angle plate, and many more.

Lathes and milling machines complement each other nicely.

Mills are cheap and take up a limited footprint. The tooling can fill a garage and cost more than the house...

Saw an advert today for a 3D Metal Printer. Maybe that's the way to go....

SEd27

XS650 Addict

Thanks for all the responses.

Looks like I will stick with my original path and keep on the lookout for an older lathe.

Looks like I will stick with my original path and keep on the lookout for an older lathe.

Last edited:

Something in the 9-12" size with 18+" between centers will do about anything you want. My atlas is a 10" swing with 36" between centers. I've turned a 6" diameter piece of 4140 into a custom axle/hub for a single sided fork, and I've profiled, chambered and threaded a custom barrel. Bigger would be nice because they are more rigid, but with patience you can do a bunch with a southbend 9" or atlas or logan 10". Up to a 13 or 14" swing won't take up much more space.

Wordman

XS650 Addict

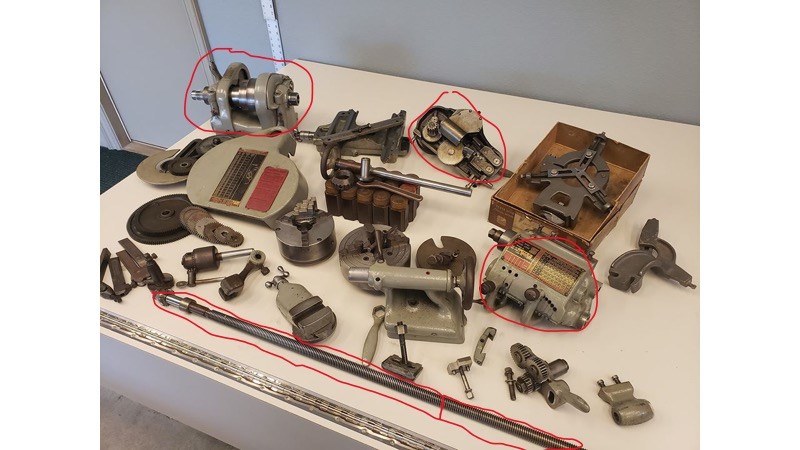

Just received everything in this photo except the screw and the headstock.

Hope you have the bed to mount all those bits on!

Wordman

XS650 Addict

Hope you have the bed to mount all those bits on!

Yes, they all go with my Southbend 9A

Last edited:

Good thing there's no room in the garage...

https://flint.craigslist.org/zip/d/lapeer-lathes-mill-drill-presses-heavy/7157232749.html

https://flint.craigslist.org/zip/d/lapeer-lathes-mill-drill-presses-heavy/7157232749.html

Good thing there's no room in the garage...

https://flint.craigslist.org/zip/d/lapeer-lathes-mill-drill-presses-heavy/7157232749.html

That group would make a great display in a museum.

Years back I visited this place in Windsor Vt:

https://americanprecision.org/category/exhibits_page/

The web site is not the best for viewing things but will give you an idea of what they have.

Similar threads

- Replies

- 9

- Views

- 898

- Replies

- 24

- Views

- 7K