-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Upgraded Sump filter and mileage change intervals

- Thread starter madmax-im

- Start date

+1 on that.....If you happen to think of where you bought these besides Mike's Id like to check it out

I've repaired one with JB weld and 1 with new screen on the outside and JB weld

I yet to have one tear anywhere, sure have seen a lot of OEMs tear. LOLIf you carefully examine your "reinforced" filter, I think you'll find that the perforated sheet metal backing doesn't run right behind the screen to support it everywhere. It veers away from the screen and ducks behind the mounting bolt tube in that area that juts out next to the magnet. Yes, the area that always tears out first, lol. So, as reinforced as these aftermarket filters may be, they don't have it where it's needed most. They'll tear out just like the originals and in the same spot.

In the pic below, the filter on the lower left is a MikesXS unit. At it's first oil change (about 1100 mi.), I found it torn and the magnet had come loose. I have to admit though, this was before I was aware of the fact that you need to take it easy until the oil warms up and thins out. I have another I've been using and it hasn't torn out yet, but I'm gentler on them now, lol.

As far as I know, there's only one aftermarket stock style filter maker. I think they all come from the same place. The only other option is the one Heiden sells. The screen is located farther away from the oil inlet on the plate so maybe tearing out wouldn't be a problem .....

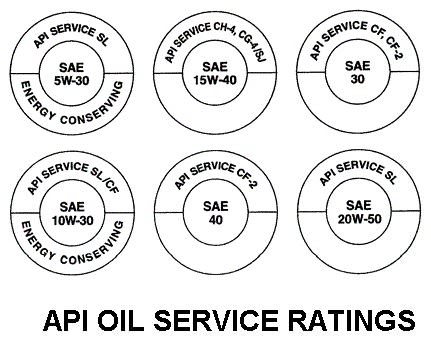

You do not want friction modifiers typically found in Energy Conserving oils such as Molybdenum..No Moly...No, not a problem. The thing you have to watch for on car oils is whether or not they are the "energy conserving" type. Those have additives that can make a wet clutch slip. Luckily, they only put them in the lighter oils, like 30wt and thinner. I'm thinking they don't help the thicker oils be any more efficient so they don't bother. Look at the API rating ring on the oil container. It will be marked if those additives are in there .....

If you want to know if a given oil is rated for use in a unit construction wet clutch motorcycle engine, look for JASO MA. Mike's XS has been claiming that Fuji sump screens were more durable than OE since the days when Lalonde did business by phone order and paper catalogue. The problem is that the fuel pump sucks a break in the screen, and reinforcement needs to be placed outside the screen to be at all effective.

They have gone up since last year.If you happen to think of where you bought these besides Mike's Id like to check it out

I've repaired one with JB weld and 1 with new screen on the outside and JB weld

https://www.ebay.com/itm/Sump-Oil-Filter-For-Yamaha-1970-83-TX650-650A-XS1-XS1B-XS2-XS650B-256-13411-01/163732678259?ssPageName=STRK:MEBIDX:IT&_trksid=p2057872.m2749.l2649

Last edited:

I respectfully beg to differ. I think the reinforcement needs to be on the inside. As 5T says they blow in. Screen flexes against backer, backer keeps it from over flexing and tearing.reinforcement needs to be placed outside the screen to be at all effective.

Have any issues been identified with a paper filter before the oil pump? In this situation it must be hard for oil to feed through to the pump. Perhaps oil starvation until the viscosity drops a bit????

Curious.

Curious.

Yuppers!

View attachment 175785

1500 miles or one change per season would be a good practice. The cheap oil mentioned is the Walmart brand 20W-50, about $12 for a 5 quart jug. I know some don't, but I like to pull the sump filter at every change and inspect it. I try to take it easy when the motor is cold and the oil is thick, but that may not happen sometimes, and I know the filter is a weak spot. I have a couple extra plate and filter assemblies so have a clean one on hand to swap in.

I recently found that one of my repaired filters had torn again, not at the repair but in a different spot, opposite of the repair, on the backside of the filter. So, it seems when we repair them, the major stress point simply shifts to somewhere else on that end of the filter around the inlet hole on the sump plate. So, I've started making sheet metal bolt-on guards for that tear-prone end of the filter. They aren't a 100% tight fit but should cut the flow and hopefully the screen stress way down. I made them removable so I could still easily inspect the screen underneath for new tears .....

You'll notice the several different templates I made up. I had to do this because I discovered that the magnets on the back side of the filters are all located differently, don't know why .....

The above pic also shows another short coming on the MikesXS "improved" filter - the magnets can break loose and fall out, lol. So, check them when cleaning those filters. Also shown is the new 2nd tear I had to repair on that one filter I mentioned above.

I have not tried it but it's going on soon with the next oil change

Might work we'll see

At that price, I'm not taking time to fix one. Fact: I have never torn one. I have found them torn, never done the tearing.

Ben,I'm never one to question the cognoscenti...The common wisdom and belief is that because of the weak sump filter prone to tearing is that mileage change intervals should be around 1200 to 1500 miles but certainly less than the Yamaha service manual recommends..I could never wrap my head around that mileage interval.

Mikes has had the upgraded metal mesh sump filters for some time now and in discussing this with the master tech.. he states 3000 miles is appropriate for oil change intervals...

View attachment 175761

I will not contradict John. He knows what he's doing. I have a tidbit for you. Based on how you say you're using this bike, mark a date on the calendar. XS650 OIL CHANGE DUE 09/2021. Repeat in 2022. It doesn't matter what screens or filters you choose. Annually should be good for you.

Tonight I changed the oil in my ride. I was pleasantly surprised to find an intact Mikes sump filter with no tears. Some time ago I cut up some perforated metal guards to patch up some old filters. I took the opportunity to JB weld in a piece in the weak spot to create a “sandwich” effect on the screen. Not sure this will be a cure, but it’s worth a shot since I had it apart.

Rwturner

XS650 New Member

BikeI'm getting the paper filter upgrade. The oil gets pretty nasty in short order with just the screens.

Also if there is a lot of hot summer riding to be done an air-cooled engine like ours can really punish the oil. It can be seen on teardown as brown baked on oil on the bottom of the Pistons and in the rockerbox.

Having rebuilt quite a few engines, any skimping on oil changes is false economy.

Also air cleaner maintenance is important.

Rwturner

XS650 New Member

Jon,there is much wisdom in your post.some riders know that engines need to reach operating temperatures before being run hard.cold flogging is never a good idea.I'm getting the paper filter upgrade. The oil gets pretty nasty in short order with just the screens.

Also if there is a lot of hot summer riding to be done an air-cooled engine like ours can really punish the oil. It can be seen on teardown as brown baked on oil on the bottom of the Pistons and in the rockerbox.

Having rebuilt quite a few engines, any skimping on oil changes is false economy.

Also air cleaner maintenance is important.

bikefreakjon

XS650 Addict

An interesting side effect of putting the EX500 carbs on my XS650 is that you have to give it a little bit of gas to start it in the morning and then it revs up to 3 or 4,000. It can't be helped. Well come to think of it I could probably put a little bit bigger choke jet in it and that would help.Jon,there is much wisdom in your post.some riders know that engines need to reach operating temperatures before being run hard.cold flogging is never a good idea.

Anyway it makes me feel good about having purchased the Heiden screen that 5twins pictured earlier as well as the paper filter upgrade kit that uses a Honda style paper element.

The upgraded cylindrical screen is made of some very thick stainless mesh and I can't imagine it blowing out anytime in my lifetime.

I also drilled and tapped the center of the 27 mm drain bolts for standard 14mm drain plugs with magnets on them so I don't need to constantly search for gigantic crush washers LOL.

Jon

I also drilled and tapped the center of the 27 mm drain bolts for standard 14mm drain plugs with magnets on them so I don't need to constantly search for gigantic crush washers LOL.

Great Idea!

Great Idea!

I bought an after market sump filter from China, instead of a flat screen on the end, the screen is the same all the way around, so, should give better service. For insurance, I made an aluminium guard that covers the end, I've drilled a series of holes in the guard though to let the oil through with obviously lower force.

Attachments

Similar threads

- Replies

- 1K

- Views

- 146K

- Replies

- 14

- Views

- 3K