It is , 9/16 - 16 TPIThe stone on that die grinder looks like the ones used on the Black and Decker valve seat grinder

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Is it my turn? Anything to do with lathes, mills and other shop tools

...and one of them needs to be shipped to me.Tool grinding / resharpening is becoming a lost art. I've not even seen these grinders used in the almost 3 years in this shop.

I believe that is what the B&D stones were!It is , 9/16 - 16 TPI

Talking about grinders, I need to dig out a grinder I think came with the old South Bend lathe I have. and post a couple pictures.

... are. CorrectI believe that is what the B&D stones were!

https://www.cylinderheadsupply.com/nesotapi.html

I still have some organizing to go, but I'm getting close to having a useable garage again. Some stuff moved out to the shed, some stuff got put where it goes, and other stuff needs a home. I'm thinking of using the black tool cart to hold vises, rotary table, indexer etc. for the mill. I just have to clear it out into the kennedy box. I still need to get a sub panel in the garage for the compressor, mills, tig and plasma.

Hey! In that last picture is that a Harbor Fright 20 ton press? I better go and check to see if mine is missing!

@Ratranger - Nice Shop!

First pic, what is that machine between the tool boxes and the Bridgeport?

Second pic, right hand side in front of the engine hoist. Looks like a bender with a trailer jack to power it? Can you provide more information on that? Curious how it works.

First pic, what is that machine between the tool boxes and the Bridgeport?

Second pic, right hand side in front of the engine hoist. Looks like a bender with a trailer jack to power it? Can you provide more information on that? Curious how it works.

Last edited:

Lol, I've had the press for about 6 years. Very useful if you have the room.

It's a small whitney horizontal mill.

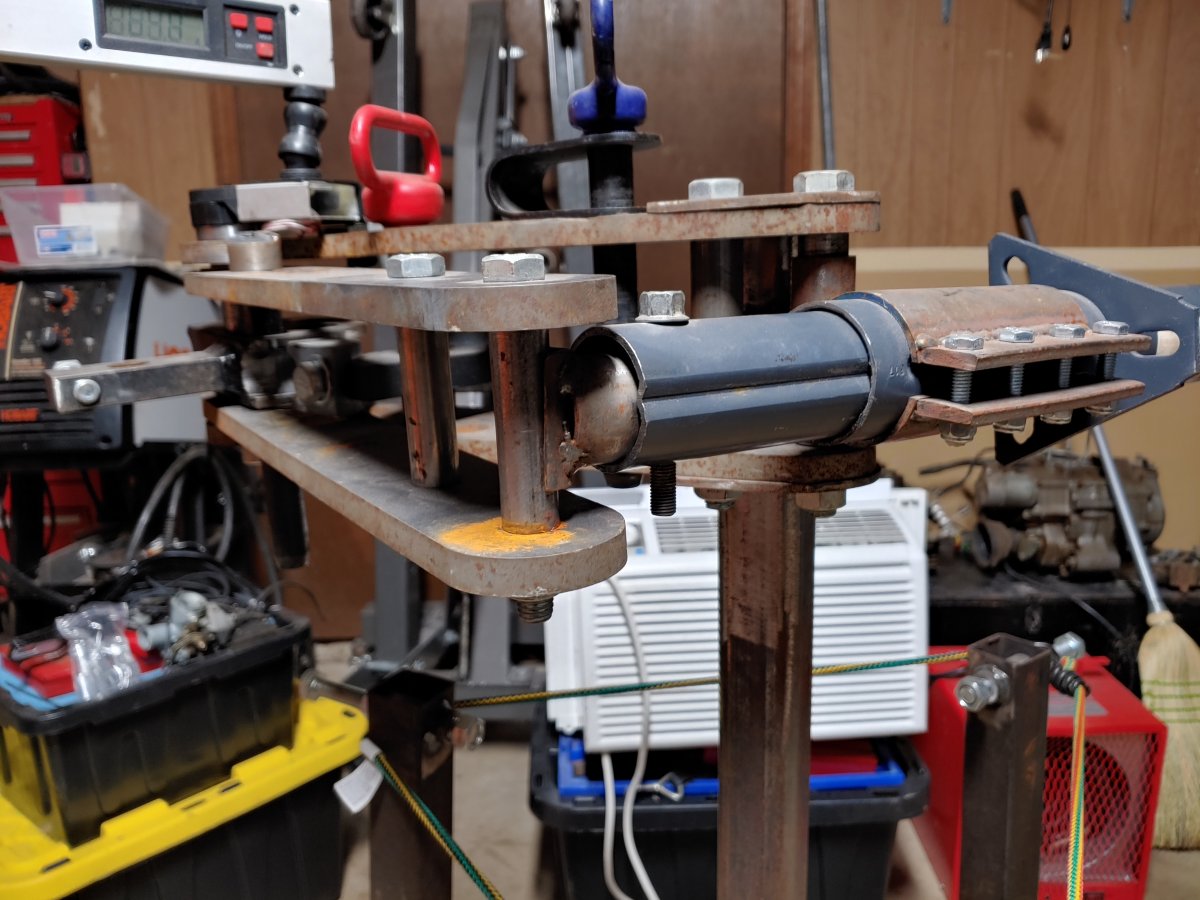

It's a home made copy of a JD2 model 3 bender. It's what I used to make the seat tube for my tracker. It works well and I did the trailer jack so I wouldn't have to bolt it down. I can get a better pic of how I set it up after work.

It's a small whitney horizontal mill.

It's a home made copy of a JD2 model 3 bender. It's what I used to make the seat tube for my tracker. It works well and I did the trailer jack so I wouldn't have to bolt it down. I can get a better pic of how I set it up after work.

Cool! Looking forward to pictures. Thanks.

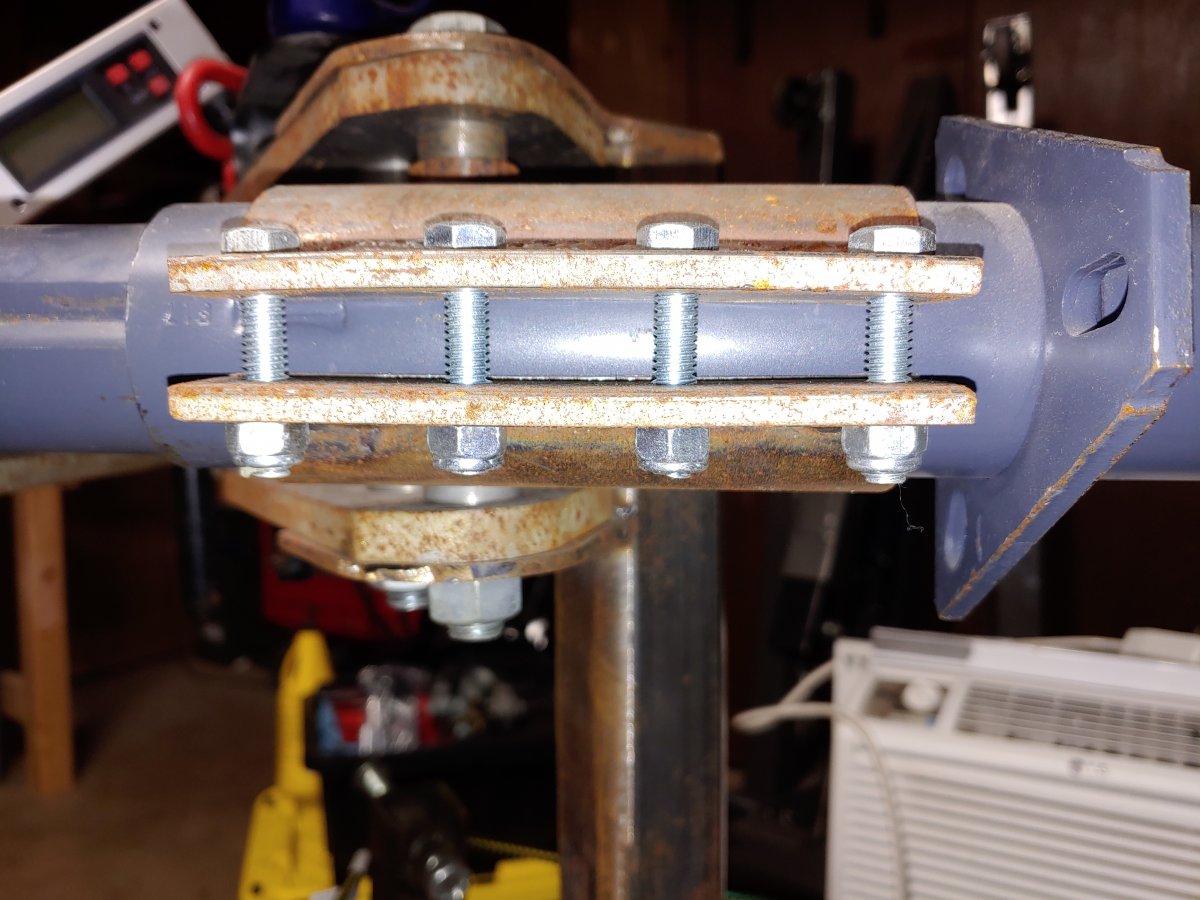

Ok, it's basically a JD2 model 3 bender on a custom stand. The stand has wheels with legs that fold for stability. The trailer jack is used in place of the ratcheting mechanism the same way a hydraulic ram would be used. To mount it I used a piece of tube the jack would fit it, welded 2 tabs on with a 1/4" gap and cut out the tube in the middle so it could clamp. On the other side I welded a piece of tube to fit over a mounting bolt as a pivot point. Where the foot would normally go I have a piece of tube with a half piece of tube welded on to push on the outer bolt without slipping off. The digital read out is a digital angle finder from harbor freight with a swag offroad kit to convert it.

While I would have loved to do a hydro set up, they are just too spendy for an occasional use tool.

While I would have loved to do a hydro set up, they are just too spendy for an occasional use tool.

Nicely done!

Very nice!

billy icon

test pilot,gunnie pig, and all around experiment

ok time to share my shop, I made this video to try and get IN TOUCH with husky toll boxex and thry and work out a deal for me to make a review video about there new boxes, but to no avail they werent interested in working with me, hmmmmm anyways just a peek into the shop im trying to put together in my new home....

IMO tool truck boxes are way too spendy. The US General from HF, Husky, Kobalt etc have some pretty good boxes for the price. I have a 44" kennedy I picked up for $200, 2 HF tool carts one modified with a side cabinet, a kennedy machinist box and the bottom from an old HF triple stack. And still have less than even a new small Icon box invested. I was looking at the husky and US General 44" boxes when I lucked into the kennedy.

I picked up the Husky tool box on the right at Deep Homo on a "scratch and dent" deal for $700.

The Kobalt shelf/drawer unit on the left came from a local surplus and salvage outfit called "Mardens". Paid right around $100 IIRC.

I can't even imagine paying $5K or more for a tool box, even if I was ass-deep in money. Makes no sense to me.

DE, I have a Snap-On box I paid right around $5k for. If I had to do it over again I would buy a much cheaper box. The difference in quality between a Snap-On and nice big box brand toolbox is nonexistent or at least not worth the massive increase in price. But when I worked at an HD dealership you were expected to have a very expensive tool box almost as a display piece to compliment the shop. The tech in the back with biggest most expensive toolbox must obviously be the best mechanic... I know it sounds stupid but that is the prevailing attitude at many OEM dealerships. If you wanted to be recognized as legitimate tech you had to have a big shiny box full of expensive tools. The reality however is that that job is 75% just changing tires, bolting on chrome, swapping exhaust, changing oil, and stroking customers egos. A trained monkey could do it, but the Illusion was that we are serious high performance engine shop ready to build you your dream machine, why just look at all these big shiny tool boxes, these guys really know their shit...

I picked up the Husky tool box on the right at Deep Homo on a "scratch and dent" deal for $700.

The Kobalt shelf/drawer unit on the left came from a local surplus and salvage outfit called "Mardens". Paid right around $100 IIRC.

I can't even imagine paying $5K or more for a tool box, even if I was ass-deep in money. Makes no sense to me.

There is a little one-man shop a ways from me that operates out of a converted shed with a couple of pipe-and-tarp shelters out back. His shop is equipped with used but well-cared-for machine tools. VERY unprepossessing. Gardner Racing Concepts.

Nicest guy you'd ever care to meet. He does tires and oil changes too, but he also builds Harley (and other) racing engines for some of the biggest names in motorcycle drag racing.

I've had him do a couple of XS jugs for me and he's always been VERY reasonable on prices. I get my tires for the FJ from him as well.

Nicest guy you'd ever care to meet. He does tires and oil changes too, but he also builds Harley (and other) racing engines for some of the biggest names in motorcycle drag racing.

I've had him do a couple of XS jugs for me and he's always been VERY reasonable on prices. I get my tires for the FJ from him as well.

Vice squad. Been looking for one with a swivel base. bit of derusting to do yet.

Nice find

Similar threads

- Replies

- 9

- Views

- 909

- Replies

- 24

- Views

- 7K