A little off subject, but there's right at a half lb. of copper in that rotor. Considerin' it's a race bike, removing that 1/2 lb of rotating mass might help a tad.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Points to GN250 Electronic Ignition Conversion

- Thread starter Jim

- Start date

Thanks Jim yes I have thought about lightening the rotor but its still very much learning to walk before the 100m hurdles for me.

After the bike had cooled, I slung the GN test rig under the bottom triple clamp, connected the plug leads up and unplugged the power to the Probe ignition.

I forgot to earth the test rig to the motor and when I powered up the GN ignition system I noticed sparking from the pickup coil terminals. I thought I had toasted the GN ignitions but after connecting the earth to the bike there were no sparks.

The bike fired up well on the GN rephased system and both advanced as hoped.

That pretty much where I am going to leave things for now until I get a standard firing motor built to repower #250.

The side cover needed a bit of metal removed from the cover plate rear screw boss and the cap screw was replaced with a pan head screw. Apart from that the cover fits as it should.

Somethings to note the pickup wires should have some heat shielding on them or even be replaced with high temperature silicon insulated wire and those horrible pre insulated spade terminals are rubbish.

Thank you Jim and Team Junk for doing the hard yards on this conversion

I forgot to earth the test rig to the motor and when I powered up the GN ignition system I noticed sparking from the pickup coil terminals. I thought I had toasted the GN ignitions but after connecting the earth to the bike there were no sparks.

The bike fired up well on the GN rephased system and both advanced as hoped.

That pretty much where I am going to leave things for now until I get a standard firing motor built to repower #250.

The side cover needed a bit of metal removed from the cover plate rear screw boss and the cap screw was replaced with a pan head screw. Apart from that the cover fits as it should.

Somethings to note the pickup wires should have some heat shielding on them or even be replaced with high temperature silicon insulated wire and those horrible pre insulated spade terminals are rubbish.

Thank you Jim and Team Junk for doing the hard yards on this conversion

Congrats Signal! Far as I know, you're the first non-TCI conversion to run.

....and also the first rephase.Congrats Signal! Far as I know, you're the first non-TCI conversion to run. View attachment 181941

There looks to be enough room there for brushes on a re-phased XS should the need arise for an active alternator. Nice bit of work there Signal.

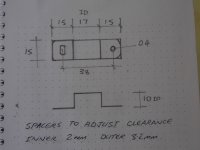

Signal, if you wouldn't mind, can you put up your bracket dimensions for the lads when you have time? My bracket's gonna be slightly different, but it would give others another option. The more the merrier eh.

If I was doing another 277 non TCI conversion I would consider positioning the rotor magnet about 15- 20 degrees anticlockwise of the stock location. This would move #2 pickup clear of the horizontal stay. There is not much of the horizontal stay left after making room for the pickup.

The vertical stay would need to be relieved for #1 pickup, but it is considerably wider.

For a standard crank the stock magnet position works well.

The vertical stay would need to be relieved for #1 pickup, but it is considerably wider.

For a standard crank the stock magnet position works well.

I like the RX coil because of the convenience of reshaping the bracket. A shunt across the pickup (ohmage to be named later) would reduce the voltage. I'm not sure its necessary. A series resistor seems to just make it advance.

Will a shunt across the pickup result in ringing and multiple firing?

Nice to see the scope traces of the stock magnet and coil and the greater voltage output of the rx coil.

Having excess voltage is easier to fix.

Thought 1

A single 4 or 5 mm hex head screw instead of a magnet.

2) smaller magnet and/or greater air gap.

Jim

Really like your "Dynamo Dynamometer" . Has a hum to it.

Try putting a pot into one of the leads of the rx pickup. Start at 0 resistance and then rotate tn some resistance and watch what happens.

Having excess voltage is easier to fix.

Thought 1

A single 4 or 5 mm hex head screw instead of a magnet.

2) smaller magnet and/or greater air gap.

Jim

Really like your "Dynamo Dynamometer" . Has a hum to it.

Try putting a pot into one of the leads of the rx pickup. Start at 0 resistance and then rotate tn some resistance and watch what happens.

Nice to see the scope traces of the stock magnet and coil and the greater voltage output of the rx coil.

Having excess voltage is easier to fix.

Thought 1

A single 4 or 5 mm hex head screw instead of a magnet.

2) smaller magnet and/or greater air gap.

Jim

Really like your "Dynamo Dynamometer" . Has a hum to it.

Try putting a pot into one of the leads of the rx pickup. Start at 0 resistance and then rotate tn some resistance and watch what happens.

I've just got a GN pickup. My next step is to test it with just a slug vs. a magnet. That will give us a better baseline on what to shoot for. At least we'll have a better idea what the output's 'sposed to be.

re post #95

Can you like a post "A lot" instead of just like ?

Can you like a post "A lot" instead of just like ?

If I put a 1981 rotor on a 1978 engine, does the woodruff key have the magnet in the right spot for correct timing?

Yup.If I put a 1981 rotor on a 1978 engine, does the woodruff key have the magnet in the right spot for correct timing?

I believe so but Jim would be the authority on that one.

So, with a 81 rotor and stator, I guess I have a good start for my '78.Yup.

Similar threads

- Replies

- 9

- Views

- 898

- Replies

- 36

- Views

- 1K

- Replies

- 30

- Views

- 2K