I still advise tappet (valve lash) adjustment before messing with carburetors. You will require feeler gauges and probably a six inch adjustable wrench will suffice. You will have to remove the tappet covers (valve covers) to do this, so you will need either paper gaskets or o'rings. I believe @gggGary may be able to help with that. You may even fix the oil leak in the process! The cam chain should also be adjusted at this time.

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

An Adventure in Firsts: '83 XS650 Heritage Special Build/Rebuild

- Thread starter MarieKaramazov

- Start date

Proper order of tuning operations for our '83's:

Cam Chain adjustment > Valve adjustment > Carb tuning

Cam Chain adjustment > Valve adjustment > Carb tuning

Your gaskets (or o-rings) might still be OK to re-use.you will need either paper gaskets or o'rings

Seeing that an oil leak exists and the source is unidentified, they are best replaced at this time.Your gaskets (or o-rings) might still be OK to re-use.

When I first got my bike my curiosity got the best of me and I ended up taking apart things just to “check things out”. In hindsight I should have just bought a complete gasket set rather than buying individual gaskets. This would have saved me time and money. If a gasket or seal is real easy to get at and looks in good shape when disassembled, sometimes I’ll clean things up and add a bit of sealer and button it back up but in most situations I’ll replace the gasket.

If you have a leaking o-ring type valve cover, many times you can fix it by simply flipping the o-ring over. This presents a fresh, unused side facing out and many times, this will seal things back up. Also, on the 3 hole covers, they can be installed in any one of 3 positions, and sometimes seal better in one of those as opposed to the others. So, if leaking, remove the cover, rotate it 120°, and reinstall. If it still leaks, try that again. If after all this, it still leaks, replace the o-ring.

I bought replacement o-rings for my '78 when I was renovating it way back in 2005 but haven't needed to use them yet. I flipped the originals, they all sealed, and are still sealing to this day. But, I can't recommend the replacements from Mike's anymore, they're very expensive. The original size has a rather oddball thickness of 2.8mm, very difficult to find, but luckily the common 3mm thick size fits and works well .....

You can get 10 packs of these off eBay, from Amazon, or McMaster-Carr for less than 4 from Mike's would cost you. You can get the plain black rubber (Buna-N) or splurge a little and get silicone ones.

https://www.ebay.com/itm/10-Pcs-Fle...47118db5d3269356ebc5|ampid:PL_CLK|clp:2334524

I bought replacement o-rings for my '78 when I was renovating it way back in 2005 but haven't needed to use them yet. I flipped the originals, they all sealed, and are still sealing to this day. But, I can't recommend the replacements from Mike's anymore, they're very expensive. The original size has a rather oddball thickness of 2.8mm, very difficult to find, but luckily the common 3mm thick size fits and works well .....

You can get 10 packs of these off eBay, from Amazon, or McMaster-Carr for less than 4 from Mike's would cost you. You can get the plain black rubber (Buna-N) or splurge a little and get silicone ones.

https://www.ebay.com/itm/10-Pcs-Fle...47118db5d3269356ebc5|ampid:PL_CLK|clp:2334524

If we give in to our impulse to just replace everything, this world of ours will quickly collapse.FWIW, I generally replace the packings every time I adjust valves. With @5twins eBay link. I will double down on that.

dammit I said no photography in the shed of ill repute!If we give in to our impulse to just replace everything, this world of ours will quickly collapse.

MarieKaramazov

XS650 Addict

Yup!Other than the quirky idle, does the engine run OK? Good acceleration, steady speed and all that?

This sounds like a good call. I bought some b12 Berryman a while back but haven't used it yet. If I use that I need to run all of it through, right? Ie. If I put enough in for a full tank, I need to ride it enough to use all the gas as I shouldn't leave product sitting in gas tank, yes?you might try putting some Sea Foam in the gas tank and just running the bike a good deal more.

When you guys are talking about the leak now, you mean the leak that's still (so far) coming from left cylinder? Or the bit of residue that was inside the cam covers? I should probably recheck if there's any in there now since I cleaned it up in the retorque. As for a possible valve leak, that smoke that was there the other day has not returned, so I feel like smoke was from burning off excess oil I put on studs during retorque--I was pretty liberal. Is doing the whole valve and cam etc necessary if I don't see a leak from valve--or you think I should look because of cylinder leak, or just a wise basic maintenance to do asap? I'm not opposed to doing it per se, I'm just trying to prioritize my tasks. Big picture is that in a little over a week, I will no longer have a car and this bike will be my only means of transportation. So most essential to the bike running well and most time consuming should be front loaded asap--any advice on that considering the current state of affairs is appreciated. Until I have a better idea of whether that means I need to get into the cam chain and valves right now, I need to change the oil and am going to try to get at that today or tomorrow, if the garbage man comes and goes early enough for me to get work done over there. Never done oil change before. Still have basic maintenance of lubing cables and brake fluid and greasing pivot points too... feeling a bit overwhelmed

If I go ahead with the valve job asap, is there a certain size feeler gauge I need?

This is the leak amount post those 2 rides the other day:

As for the cylinder leak, I forgot to mention this after I did the retorque. I skated by it a bit because, well, I really wanted to move forward, but perhaps that was a bad call... When I removed the bolt under the LH cylinder spark plug, I saw a few shavings on the bolt and one in the threaded hole itself. It was really hard to tell whether the shaving was coming from the hole being stripped or the bolt threads. My money is the bolt though. I got rid of any I saw inside the hole (thankfully still clinging to side and not fallen in--though I have no idea if some has before...possible leak cause if this has gotten into cylinder?) and made sure the bolt felt smooth. Replacement or pausing etc may have been wiser, but I was impatient and went for it.

In other news...

Took a second just to check on idle yesterday to see if it was still going to take a while. Took me about 8+ times (long holds on starter button and pausing between) to get the bike to start with the electric start... It was probably 68-70 degrees. I know the bike is old, but should it really be putting up this much of a fuss to start? Once it started, I could kill it and start it again right away. So cold starting seems harder for it... Spark plugs were replaced just a few months back. Maybe if I take it out today I'll check the spark plugs after.

Side notes:

What do you guys think about compression test priority? I asked and a friend of mine has a compression gauge at their shop and now that I'm (mostly) running okayish I'm thinking I zip over there and try it; after I figure out how to do said test...

I'm thinking I really need to get through this Haynes Motorcycle Basics Techbook asap so I understand what I'm doing and why. It's driving me a little nuts that I don't know why I'm doing certain things as I like to understand that to really know how it works, and why, and then be able to diagnose and solve better as well.

Also, still wondering if I was wrong not to use a specific torque on the motor mount? I just went with tight...

! I just remembered I forgot to check the wear on my generator brushes...I bought new ones but didn't look to see if they need switching out yet. Ohh, and that very small oil dangle from the front two acorns nuts...ay!

Okay this is a lot of things I'm going to stop. Thinking out loud a bit in an effort to organize everything and get a grasp on order of attack

About the torque. Unless specified otherwise torque values are generally specified for clean, dry threads. When you apply oil to those threads, the torque is increased.

The steel bolt going in the aluminum hole won’t strip. The aluminum will. Whatever you break, a machinist can fix, but you have to bring them the part you broke.

So, be careful when you put that bolt back. With lube torque it will strip, so back off on it.

Don’t concern yourself with the rest of the bolts you torqued. You didn’t hurt anything.

The steel bolt going in the aluminum hole won’t strip. The aluminum will. Whatever you break, a machinist can fix, but you have to bring them the part you broke.

So, be careful when you put that bolt back. With lube torque it will strip, so back off on it.

Don’t concern yourself with the rest of the bolts you torqued. You didn’t hurt anything.

Recommended Priority: Ride the bike for awhile, relax, have some fun and appreciate all the hard work you've done.Thinking out loud a bit in an effort to organize everything and get a grasp on order of attack

If the bike runs, it has enough compression. If you want to check, it won’t hurt, but better to check valve lash first.

I agree. Doing a compression test will only open up a bad can of worms. I suggest that you forget about it.If the bike runs, it has enough compression.

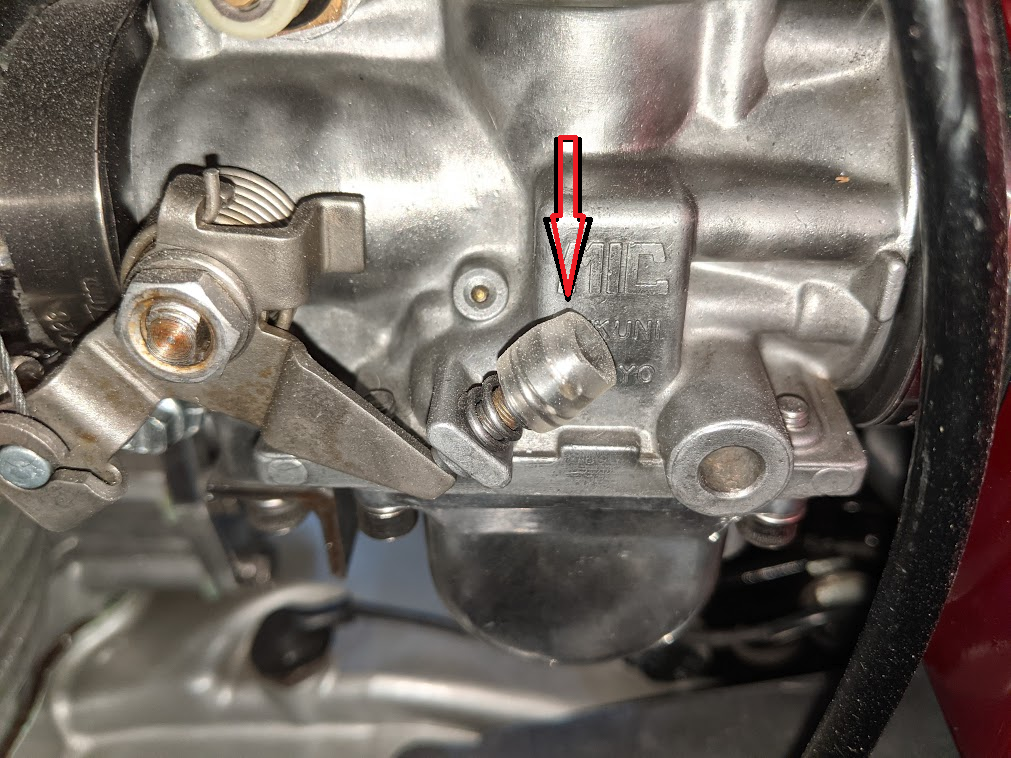

Well if it seems to run good, I'd put some miles on it and see if the idle settles down. You can take a small (1") section of fuel line and slide it down over the idle screw. Makes it easier to adjust with your fingers at a stoplight.Yup!

As far as the oil leaks on the top end go, you'll need to put some miles on it to see if they'll settle down. Go for a ride girl.

RE: cam chain and valves... yes they need doin'. But.... if you're down to a week, no they're not a priority, any reliability issues are the priority. Loose chain and valves will make the engine a little noisier and power will be down just a tad... other than that it won't hurt anything.

Oil change should be the next priority.

That's not good. Bolt is steel, hole is aluminum. Those thread remnants are most likely alum. from the hole. Properly fixing that will require pulling the top end apart. But..... if that bolt took the torque it's supposed to.... leave it alone!! It'll hold for now, but I doubt it would stand another retorque... trust the Beetles... let it be.As for the cylinder leak, I forgot to mention this after I did the retorque. I skated by it a bit because, well, I really wanted to move forward, but perhaps that was a bad call... When I removed the bolt under the LH cylinder spark plug, I saw a few shavings on the bolt and one in the threaded hole itself. It was really hard to tell whether the shaving was coming from the hole being stripped or the bolt threads. My money is the bolt though. I got rid of any I saw inside the hole (thankfully still clinging to side and not fallen in--though I have no idea if some has before...possible leak cause if this has gotten into cylinder?) and made sure the bolt felt smooth. Replacement or pausing etc may have been wiser, but I was impatient and went for it.

Was gonna say not a priority but I suppose low compression could be aggravating the hard starting issue. Sometimes just putting some miles on an engine that's sat will bring compression back up to acceptable. Here's the rub though... low compression will mean a top end overhaul. Not something you can get done in a week. Prolly best to just let it be for now.... put that on your low priority list.What do you guys think about compression test priority? I asked and a friend of mine has a compression gauge at their shop and now that I'm (mostly) running okayish I'm thinking I zip over there and try it; after I figure out how to do said test...

I don't torque 'em either. Just get 'em tight and recheck (visual) periodically.Also, still wondering if I was wrong not to use a specific torque on the motor mount? I just went with tight...

Yes, worn brushes can leave you stranded with a dead battery. That's a priority.... check the brushes, change the oil and put some miles on 'er.! I just remembered I forgot to check the wear on my generator brushes...I bought new ones but didn't look to see if they need switching out yet. Ohh, and that very small oil dangle from the front two acorns nuts...ay!

Small section of fuel line on idle screw.

Are you using the choke for your cold starts? Even in warm weather, you usually need it. You shouldn't have to leave it on long after starting in warm weather, but it is needed to start easily and quickly. The cold motor needs that initial shot of extra rich fuel mixture.

Your valve clearance specs are .003" for the intakes and .006" for the exhausts, so get a feeler gauge that has those sizes. Normally, valve clearances loosen up over time and you get ticking noises from the topend. Watching the video you posted of the bike running, the valves don't appear to be ticking (loose) but ..... they could be too tight. The valves need clearances so that as the bike heats up and parts expand, the valves will still close completely. If they don't, the bike can start running badly or even stall. Your falling idle speed once hot could also be an indication that some of the valves may be a bit tight.

You've showed your oil leak again but that's where the oil is ending up. You have to trace down where it's coming from, lol. It could be from one of several places above where it's pooling. It could very well be from the head gasket (that you tried fixing with your re-torque) but may also be from the cam seal or the cam chain adjuster on the back of the motor. Oil leaking from any of those spots would eventually run down the cylinder fins and end up where you've shown it. So yes, pull that cam cover off again and see if it's full of oil inside again.

Your valve clearance specs are .003" for the intakes and .006" for the exhausts, so get a feeler gauge that has those sizes. Normally, valve clearances loosen up over time and you get ticking noises from the topend. Watching the video you posted of the bike running, the valves don't appear to be ticking (loose) but ..... they could be too tight. The valves need clearances so that as the bike heats up and parts expand, the valves will still close completely. If they don't, the bike can start running badly or even stall. Your falling idle speed once hot could also be an indication that some of the valves may be a bit tight.

You've showed your oil leak again but that's where the oil is ending up. You have to trace down where it's coming from, lol. It could be from one of several places above where it's pooling. It could very well be from the head gasket (that you tried fixing with your re-torque) but may also be from the cam seal or the cam chain adjuster on the back of the motor. Oil leaking from any of those spots would eventually run down the cylinder fins and end up where you've shown it. So yes, pull that cam cover off again and see if it's full of oil inside again.

I'm gonna respectfully disagree with the valve clearances (possibly) causing the low idle. It's been my experience on just about any aluminum head engine I've ever worked on, the clearances increase when warmed up, not decrease. And just anecdotally, the valves on my 80 are noticeable louder when it's hot. The valves in Marie's videos sound plenty loose to me.

Having said that, it won't hurt to check 'em. Depends on how much time's left on the clock when all the other stuff is sorted.

Having said that, it won't hurt to check 'em. Depends on how much time's left on the clock when all the other stuff is sorted.

Last edited:

Pretty gutsy to take on all of these unfamiliar wrenching tasks, on an XS to ride daily, Kudos!

Oil changing can be kept to just the oil and right side filter for now. (20-50wt) That sump screen cleaning task, way under the engine, let's just assume it will be cleaned at a more convenient time.

About the Berryman B-12? Well, just how strong is that? I tend to stay away from chemicals in the carbs in favor of just good quality premium gasoline. Draining the carburetor float bowls is a very easy and important task, to flush out debris in the bowl.

At least checking the valve clearances for gap is also easy and reassuring that there are no "too tight" clearances.

I'm in the "ride it" camp now as you need to figure out which leaks are important, or not, and to figure out the carburetor adjustments perhaps.

Cheers !

Oil changing can be kept to just the oil and right side filter for now. (20-50wt) That sump screen cleaning task, way under the engine, let's just assume it will be cleaned at a more convenient time.

About the Berryman B-12? Well, just how strong is that? I tend to stay away from chemicals in the carbs in favor of just good quality premium gasoline. Draining the carburetor float bowls is a very easy and important task, to flush out debris in the bowl.

At least checking the valve clearances for gap is also easy and reassuring that there are no "too tight" clearances.

I'm in the "ride it" camp now as you need to figure out which leaks are important, or not, and to figure out the carburetor adjustments perhaps.

Cheers !