buzzword

XS650 Addict

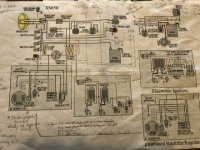

View attachment 183232

You've Clearly put much thought and consideration in all your components. Please share your opinion of the variations of the cam chain tensioner. The type "D" vs the "E" with the added lock nut.

View attachment 183233

Yes, you should upgrade or update your type D tensioner to a type E. The "how" and, more importantly, the "why" are in posts 22 and 23 here .....

http://www.xs650.com/threads/cam-chain-tensioners.1056/page-2

I'd definitely prefer a Type E - just couldn't find one when I went to replace the stock '75 tensioner. I really don't want the high profile one the motor shipped with. To be honest, this one is a bit of a mockup placeholder. Anyone have a Type E for sale?