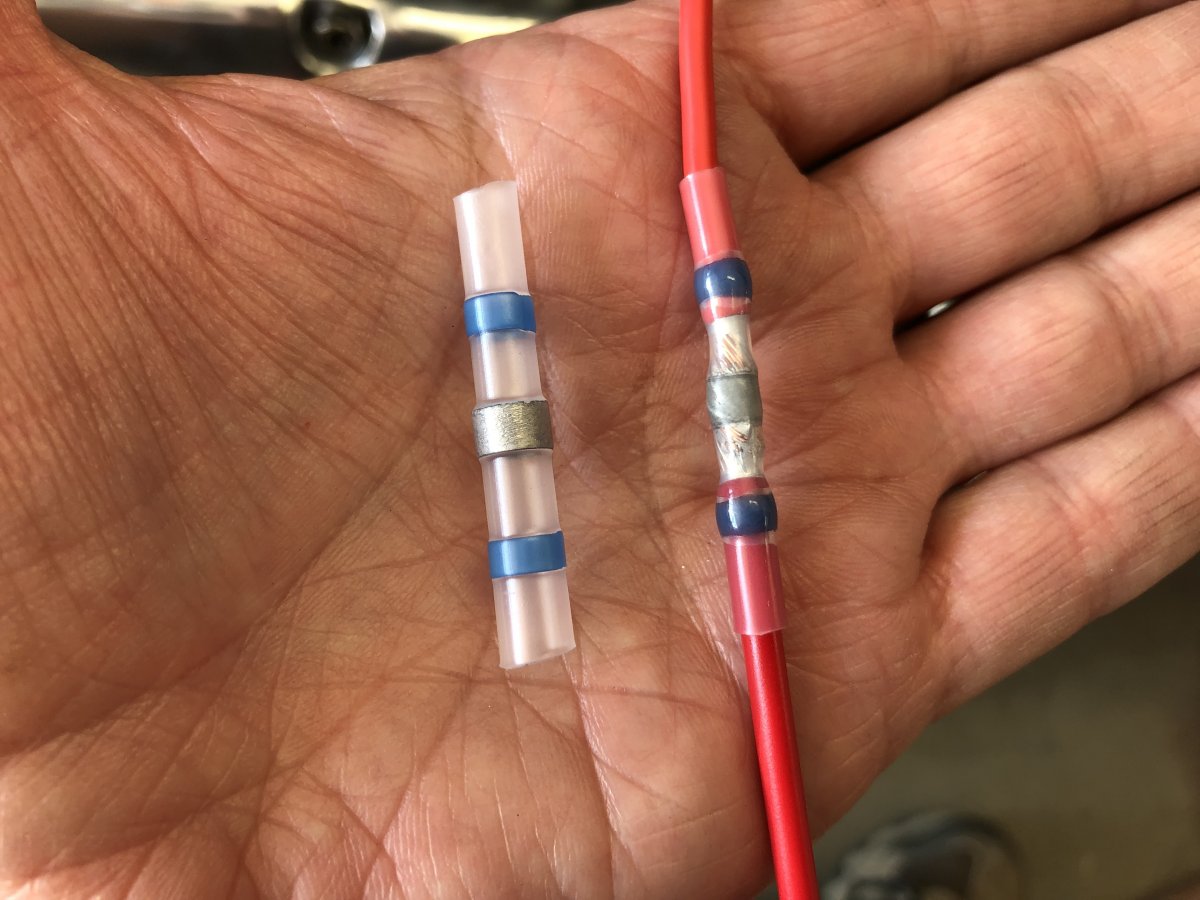

So a while back I bought a box of self soldering heat shrink connectors in assorted sizes from Amazon.

I tried them for the first time today, I made three wire connections. At first I thought they did a pretty good job, they looked to be tinned over the connection and I really liked the way the heat shrink tubing with the blue hot glue melted down and held the wire securely.

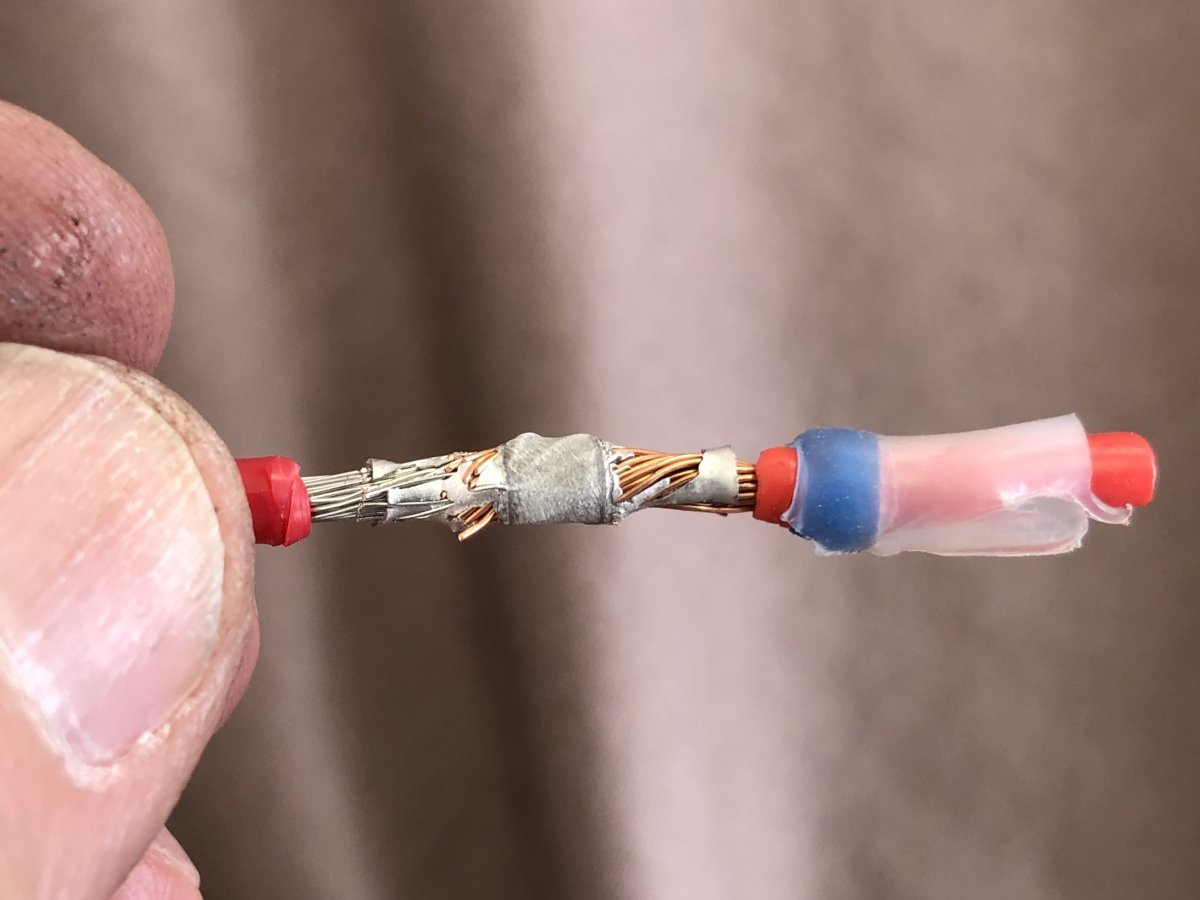

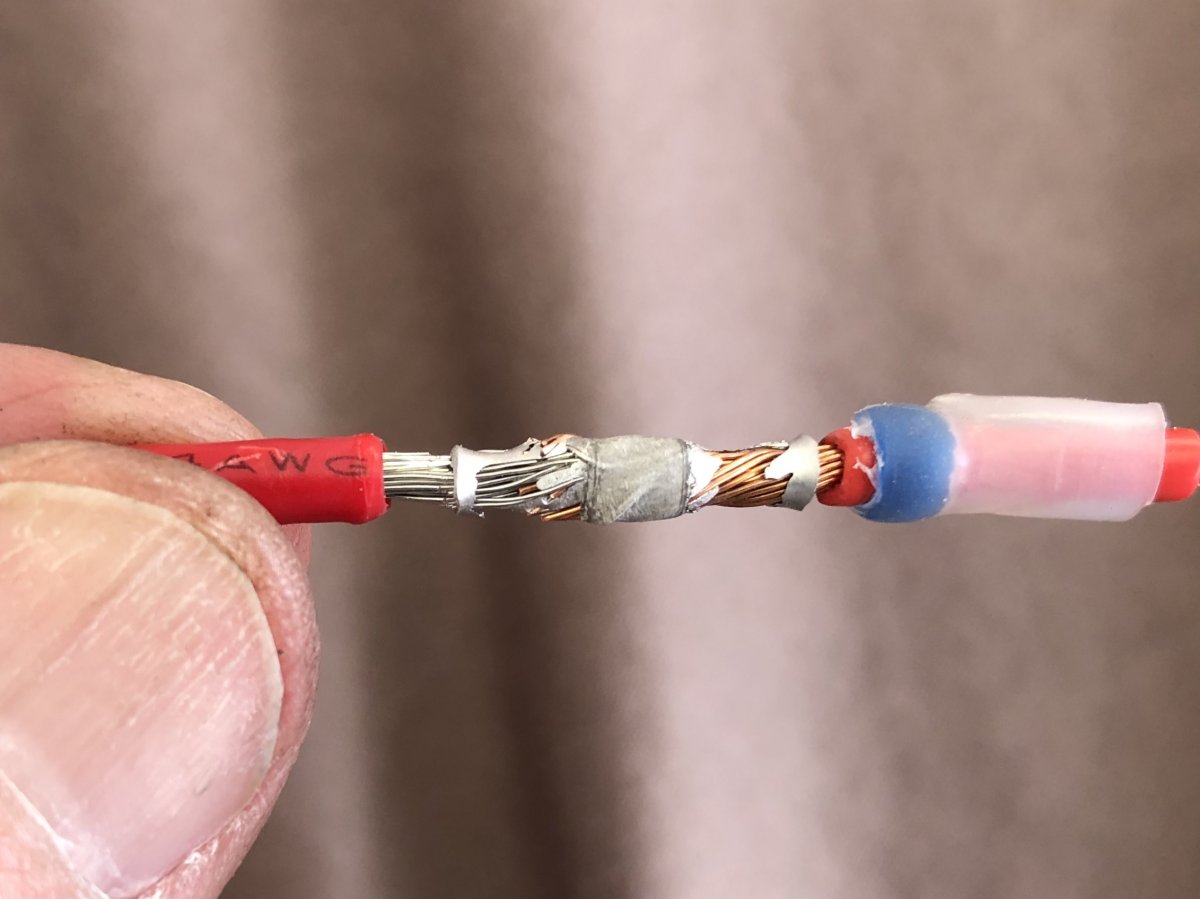

Closer inspection however revealed wires that had no solder on them, so I cut the heat shrink off one of them so I could get a better look. The solder was sketchy at best, only connected here and there.

I am going back to my old dependable soldering iron. I should’ve known, if it sounds too good to be true, it probably is. I won’t use them again.

Conclusion………..? Spend your money on something else!

I tried them for the first time today, I made three wire connections. At first I thought they did a pretty good job, they looked to be tinned over the connection and I really liked the way the heat shrink tubing with the blue hot glue melted down and held the wire securely.

Closer inspection however revealed wires that had no solder on them, so I cut the heat shrink off one of them so I could get a better look. The solder was sketchy at best, only connected here and there.

I am going back to my old dependable soldering iron. I should’ve known, if it sounds too good to be true, it probably is. I won’t use them again.

Conclusion………..? Spend your money on something else!