1973 TX650 Chopper

XS650 Member

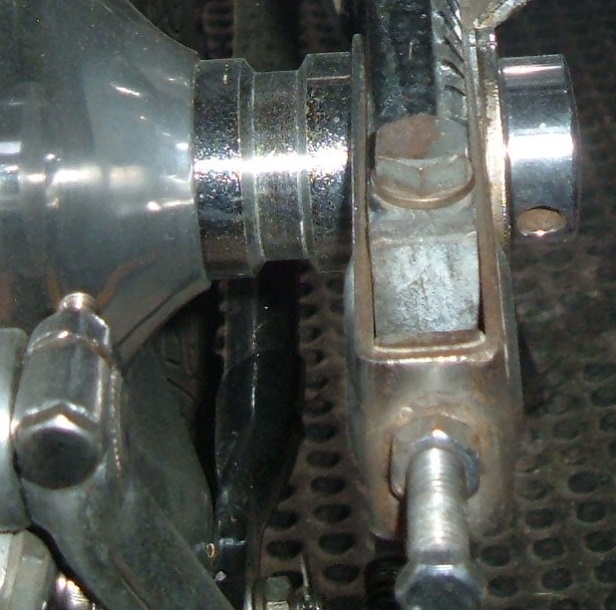

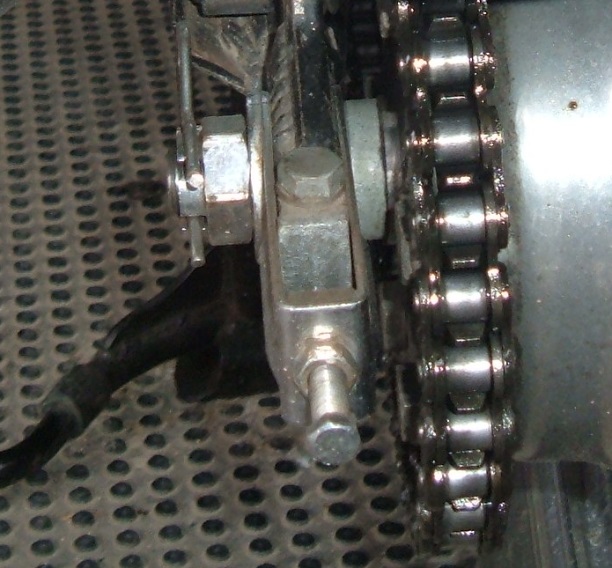

Hey everyone. Love this site! I have a 1973 TX650 custom hardtail. I bought it 80% complete and I've finished it. My problem is the rear wheel is wobbly and loose. I noticed this when I raised the rear wheel off the ground. The wheel wobbles back and forth way too much. I tried to tear the rear wheel assembly apart to inspect, but then I ran into another problem. I can't get the nut off the axle! I'm starting to wonder if the original owner made a custom rear axle. There is a small hole about 1/4 inch into the axle end where normally there would be a hole drilled all the way through so you could put a rod to keep the axle from turning while removing the nut from the opposite end. This has prevented me from keeping the axle from spinning while removing the nut. I've tried my impact gun but nothing works. I tried drilling through the axle to make it like the original versions, but I can't make a dent in the axle end.

Do you think I should get someone to weld something onto the axle so I can grip it? Drilling the hole doesn't seem to work.

Once I remove the axle then I need to figure out why the wheel is wobbly. I'm wondering if the original owner put in too small of an axle, if he made his own. I have the diagrams of the rear axle differences from this site. I also have the original 1973 axle which the nut doesn't fit the current axle. Original nut is too big leading me to believe maybe it's too small of an axle in there causing the wobble. I'm going to try and attach pictures of the wheel hub area showing the gap / difference in the wheel wobble.

What's the best way to get this axle off since I can't grip it on one end?

Any idea why the wheel would wobble if it isn't an incorrect axle?

Do you think I should get someone to weld something onto the axle so I can grip it? Drilling the hole doesn't seem to work.

Once I remove the axle then I need to figure out why the wheel is wobbly. I'm wondering if the original owner put in too small of an axle, if he made his own. I have the diagrams of the rear axle differences from this site. I also have the original 1973 axle which the nut doesn't fit the current axle. Original nut is too big leading me to believe maybe it's too small of an axle in there causing the wobble. I'm going to try and attach pictures of the wheel hub area showing the gap / difference in the wheel wobble.

What's the best way to get this axle off since I can't grip it on one end?

Any idea why the wheel would wobble if it isn't an incorrect axle?

Attachments

Last edited by a moderator: