OakBehringer

XS650 Guru

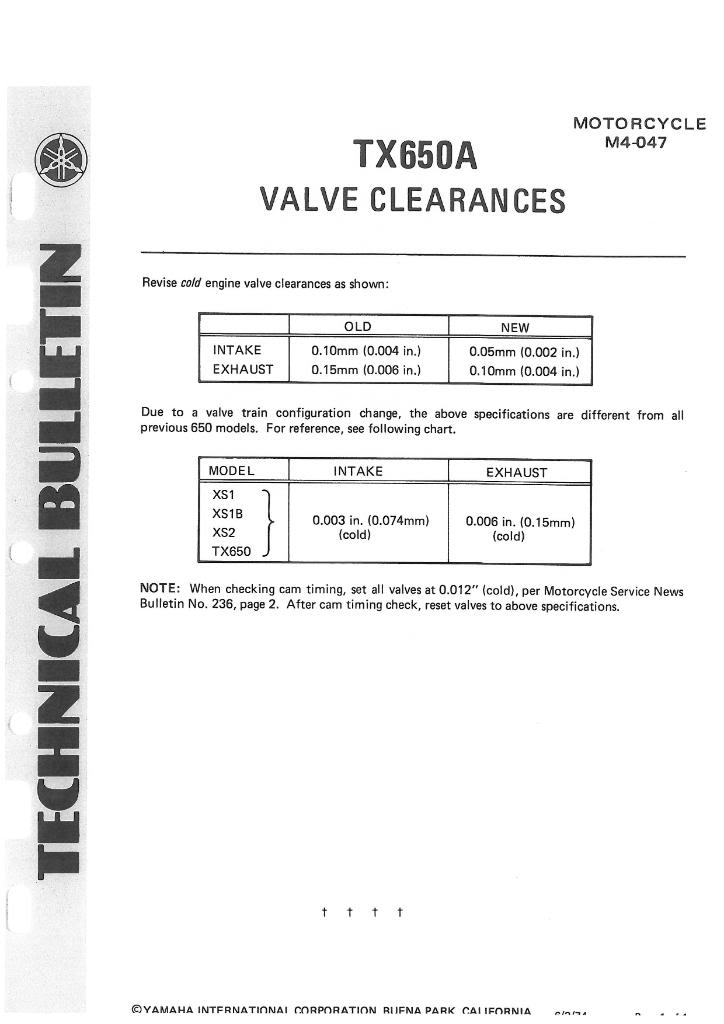

Intake/Exhaust

MikesXS and 650Central: .006 / .012

Various posts on this form: .003 / .006

My Clymer: (don't remember, I think it lists the same for both, though!)

Other sites on the Internet: a myriad of different values

I just noticed these varying specs. Anyone have the correct answer with a reliable reason? I'm inclined to go with .006/.012 to be safe.

MikesXS and 650Central: .006 / .012

Various posts on this form: .003 / .006

My Clymer: (don't remember, I think it lists the same for both, though!)

Other sites on the Internet: a myriad of different values

I just noticed these varying specs. Anyone have the correct answer with a reliable reason? I'm inclined to go with .006/.012 to be safe.