UPDATE

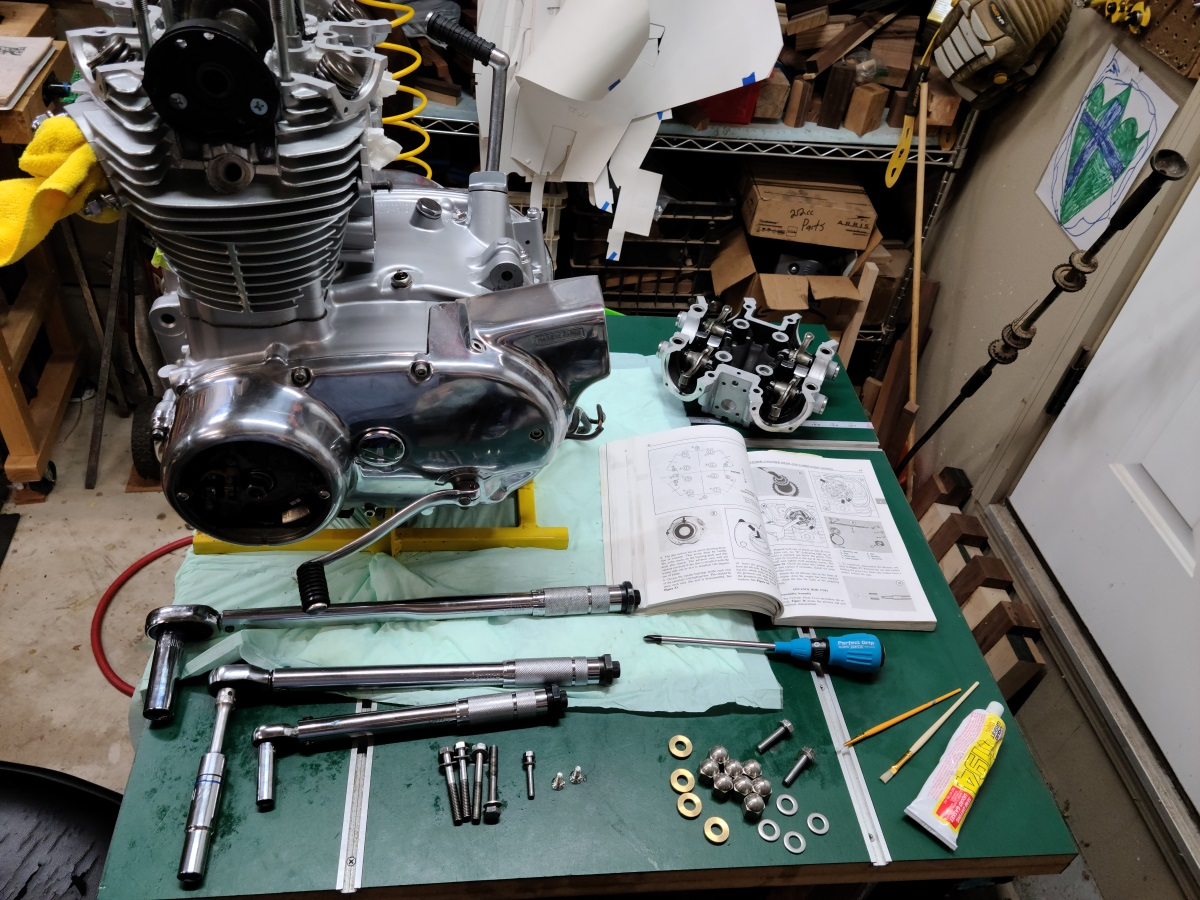

I was able to get quite a lot done this week! Picking back up with installing the jugs - first step was to split the rear cam chain tensioner as I am using an endless chain. I found that a ½” drill bit was the perfect size to knock that lip off the rivet so I could separate it enough to get the chain in.

@Jim, your method of using the 4” pieces of wood worked great, but I found it made much more sense for me to insert the pistons from the bottom. @Mailman, your Popsicle stick method worked great, so simple! Stuffing the crankcase full of rags was also a good idea, as I dropped the clips about 10 times while trying to install it…

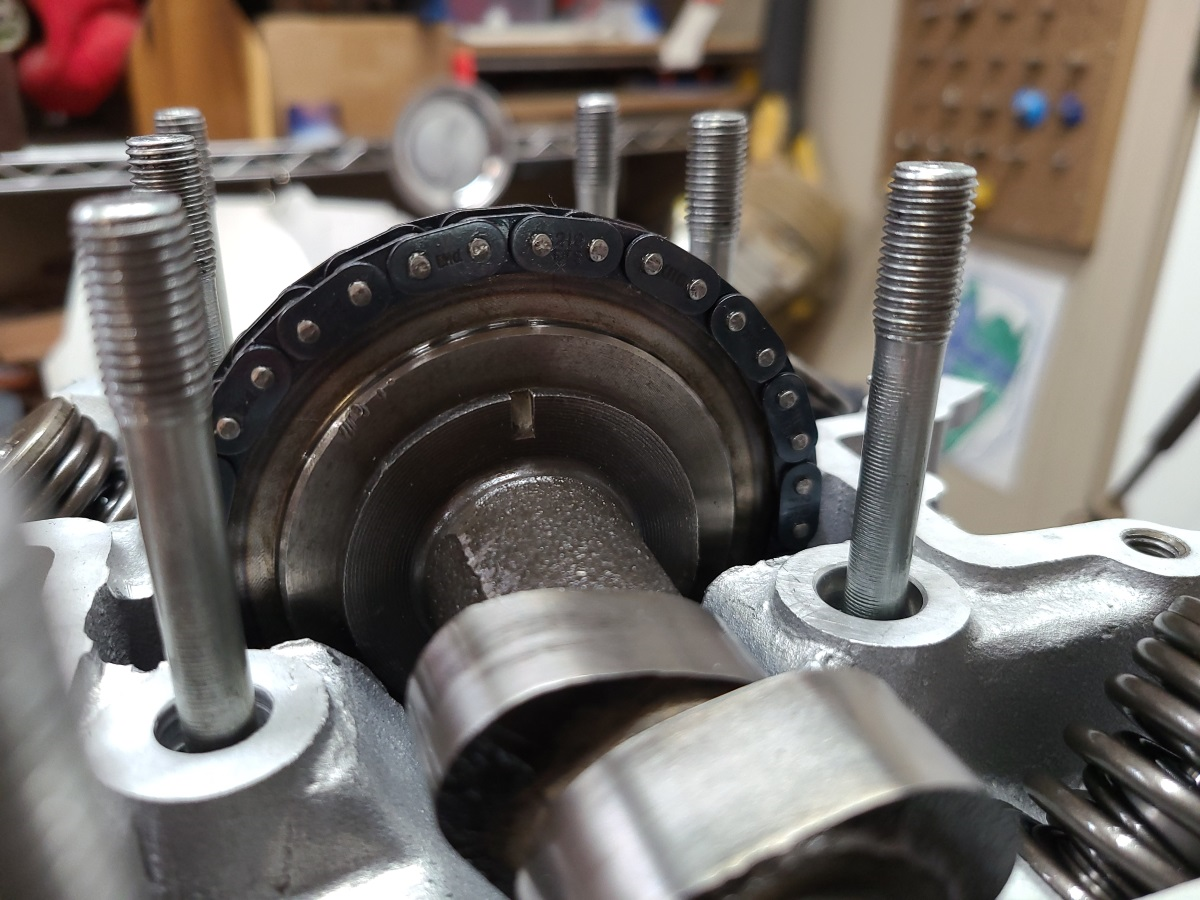

The head went on without issue and that left me with the cam chain. From now on when people ask me, “Rhy, what are you most proud of…” the answer will not be “my family” or “my career”, it will be “getting that f@&%ing cam chain installed”. It was tight, really tight. I went through a good period of thinking it was the wrong chain, that I had assembled something wrong, it was not allowable by the laws of known physics, etc… If anyone else is struggling with and endless chain I found that it was necessary to get the chain over the cam without the cam bearings. Even that was a struggle and it was only possible by inserting the cam into the chain from the left side of the engine, make sure there are no kinks in the chain down in the crankcase. Once you get the chain over the cam put one bearings on one side, then another bearing the other. I was able to gently tap in the two remaining bearings once it was seated. Expect to use much force the whole time.

Next up was torqueing down the whole top end. I did lots of prep work on this, clamped the engine to my workbench and it went very smoothly.

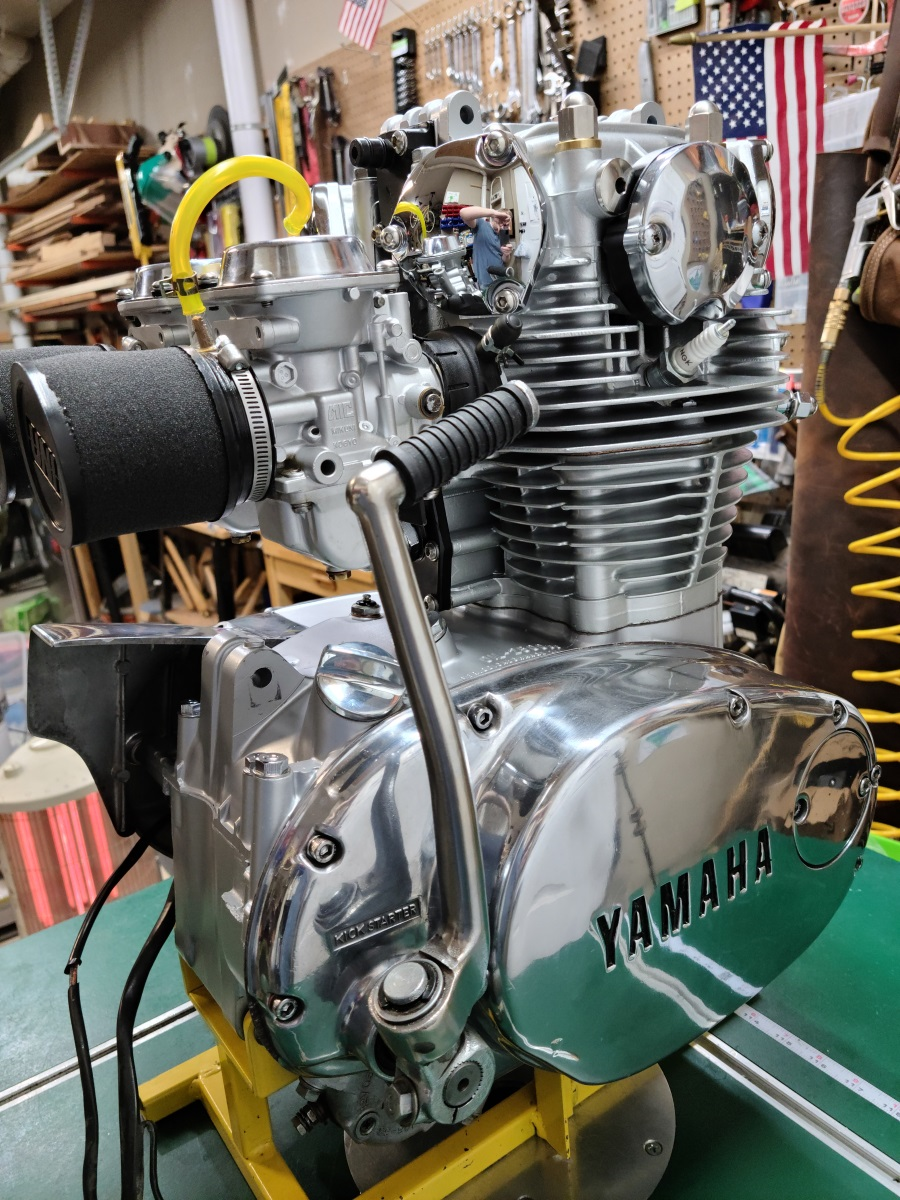

After getting it tightened down, I installed the breather, cam chain adjuster, and point covers. Really liking the black/stainless/aluminum combination.

All that was left was to set the valves, valve covers, oil delivery, and spark plugs. I attempted to polish the old valve covers, but couldn’t get them to where I wanted them, so I splurged on a set of new ones. In my opinion, the head of this engine is a big part of what makes it look so cool, certainly my favorite part of the bike.

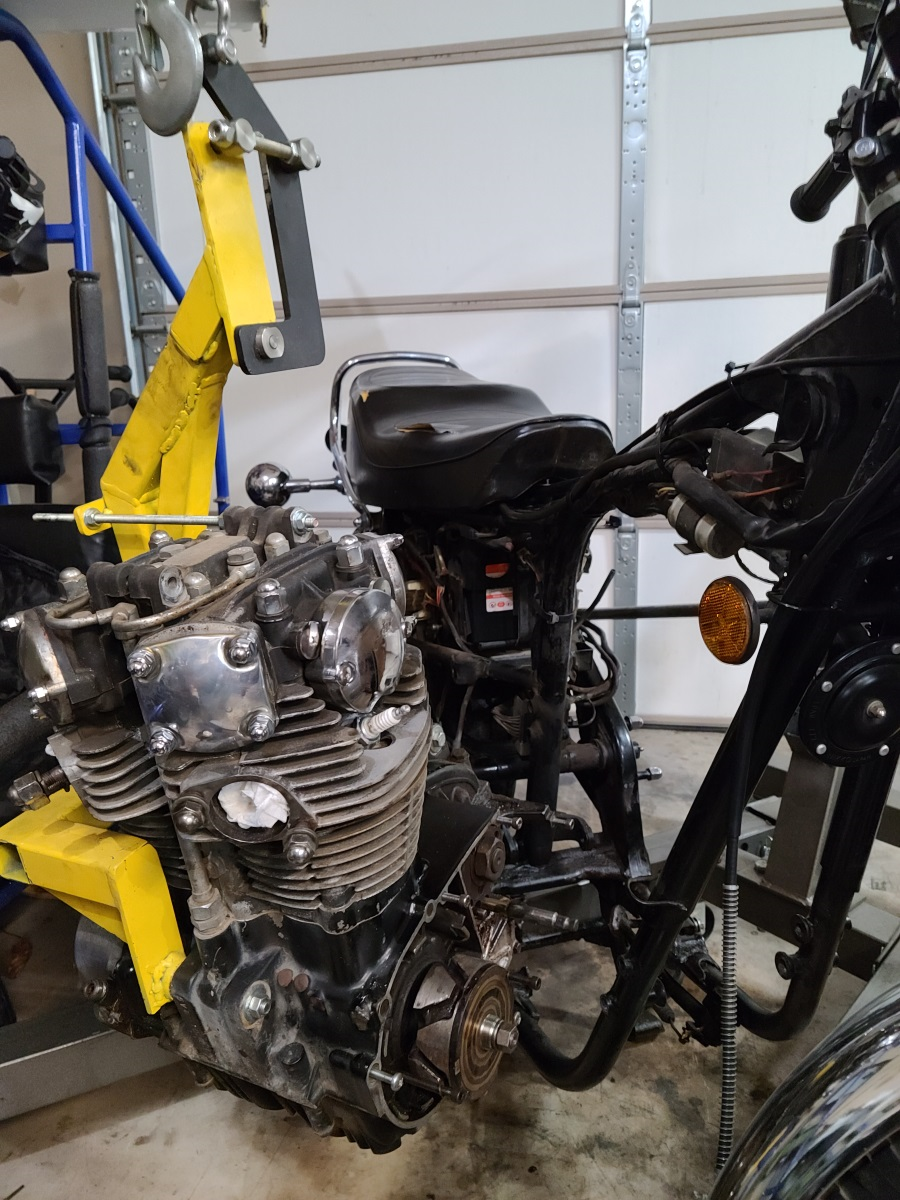

So here it is, the finished product (I built the carbs before starting this log):

Now to get it into the motorcycle… I am very grateful to have this engine hoist jig that Dad made. Together with the engine lift I was able to get the old one out without much issue, even as a single man operation.

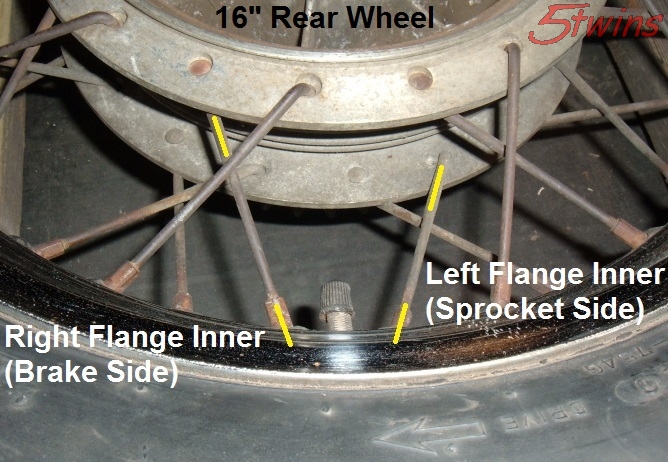

My OCD is having a hard time not just ripping the whole bike apart and cleaning/repainting/polishing everything. However, the desire to have a running motorcycle prevailed so I have resigned myself to putting it back together. I’m going to try and save the real neuroticism for the ’71. The final steps to finish this bike are to recover the seat and rebuild the wheels. I plan to re-lace with stainless spokes, polish the hubs, and replace the bearings/seals. Anyone have a good source of information about lacing wheels they could point me towards? Also, I will likely end up replacing the rear tire if anyone has any recommendations for tire brands, vendors, tread, etc... I believe it is a 130/90-16. Thanks in advance!

I was able to get quite a lot done this week! Picking back up with installing the jugs - first step was to split the rear cam chain tensioner as I am using an endless chain. I found that a ½” drill bit was the perfect size to knock that lip off the rivet so I could separate it enough to get the chain in.

@Jim, your method of using the 4” pieces of wood worked great, but I found it made much more sense for me to insert the pistons from the bottom. @Mailman, your Popsicle stick method worked great, so simple! Stuffing the crankcase full of rags was also a good idea, as I dropped the clips about 10 times while trying to install it…

The head went on without issue and that left me with the cam chain. From now on when people ask me, “Rhy, what are you most proud of…” the answer will not be “my family” or “my career”, it will be “getting that f@&%ing cam chain installed”. It was tight, really tight. I went through a good period of thinking it was the wrong chain, that I had assembled something wrong, it was not allowable by the laws of known physics, etc… If anyone else is struggling with and endless chain I found that it was necessary to get the chain over the cam without the cam bearings. Even that was a struggle and it was only possible by inserting the cam into the chain from the left side of the engine, make sure there are no kinks in the chain down in the crankcase. Once you get the chain over the cam put one bearings on one side, then another bearing the other. I was able to gently tap in the two remaining bearings once it was seated. Expect to use much force the whole time.

Next up was torqueing down the whole top end. I did lots of prep work on this, clamped the engine to my workbench and it went very smoothly.

After getting it tightened down, I installed the breather, cam chain adjuster, and point covers. Really liking the black/stainless/aluminum combination.

All that was left was to set the valves, valve covers, oil delivery, and spark plugs. I attempted to polish the old valve covers, but couldn’t get them to where I wanted them, so I splurged on a set of new ones. In my opinion, the head of this engine is a big part of what makes it look so cool, certainly my favorite part of the bike.

So here it is, the finished product (I built the carbs before starting this log):

Now to get it into the motorcycle… I am very grateful to have this engine hoist jig that Dad made. Together with the engine lift I was able to get the old one out without much issue, even as a single man operation.

My OCD is having a hard time not just ripping the whole bike apart and cleaning/repainting/polishing everything. However, the desire to have a running motorcycle prevailed so I have resigned myself to putting it back together. I’m going to try and save the real neuroticism for the ’71. The final steps to finish this bike are to recover the seat and rebuild the wheels. I plan to re-lace with stainless spokes, polish the hubs, and replace the bearings/seals. Anyone have a good source of information about lacing wheels they could point me towards? Also, I will likely end up replacing the rear tire if anyone has any recommendations for tire brands, vendors, tread, etc... I believe it is a 130/90-16. Thanks in advance!

(but please DON'T TELL my wife). Remember that there is a fairly flexible tire filled with quite flexible air - between your bum and the road and so a mm of up-and-down and sideways isn't likely to feel like much to the rider (totally aside from how smooth the road itself is). Balancing the wheel and tire assembly (using lead weights) will help a lot with smoothness.

(but please DON'T TELL my wife). Remember that there is a fairly flexible tire filled with quite flexible air - between your bum and the road and so a mm of up-and-down and sideways isn't likely to feel like much to the rider (totally aside from how smooth the road itself is). Balancing the wheel and tire assembly (using lead weights) will help a lot with smoothness.