That's good news! Thanks 5twins!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1980 SG Back From The Dead – AKA Dad’s bike

- Thread starter Mike G

- Start date

There is a washer and rubber O ring on the bottom of the idle mixture screws. The screws should bottom out without any force.......when i dismantled a set of BS34 carbs the washer was bent over double so someone must have screwed down the screw hard to do that.

If you had to use force i would be doing some investigating to try to find a reason for............. Also forcing them in it will damage the rubber O ring

If you had to use force i would be doing some investigating to try to find a reason for............. Also forcing them in it will damage the rubber O ring

After correcting the issue with the pilot mixture screws and setting the floats for a fuel level 1mm below the carb body lip the bike ran MUCH better, well enough to let me sync the carbs and set the idle speed. At this point it started well and revved nicely when blipping the throttle so it was time to buy a Yuasa AGM and finally ride the beast after its nearly 20 year slumber to find out if there were any more problems that would only crop-up while riding. This is how she looked out in the sunlight for the first time last Saturday.

I hit the starter button and thankfully no grinding noises, she just rolled over about twice and started right up! I let it warm up a little and rode it around the neighborhood for about 7 miles (no plates or insurance yet) and noticed that the shift lever was too low, the upper triple clamp clamp bolt was loose (woops!) and I could only get the left flashers to work if I used the right one first. I was fairly pleased that was all that was wrong with it and it did pull well from just off idle and revved well to 6000 rpm. It would have revved higher but the bars get awful lively up there so that’s as far as I cared to go.

When I got back home I did some searching on the forum and found the flasher was likely a bad solder joint so I pulled the left control off and pulled it apart and sure enough one of the wires pulled right off. I re-soldered the faulty joint, cleaned and lubed everything and now all is well. I’m declaring it roadworthy and finished or at least as finished as any project gets. I am planning on getting plates and insurance this week and give her a proper shake down cruise this weekend.

The next item will be replacing the special tank with a standard tank and swapping the stock 1975 gas cap mount (the tank came without a cap) for a similar vintage Honda CB cap which I think looks better anyway and didn’t cost anything. I haven’t done much welding on material as thin as the tank so it should be a learning experience but I can get plenty of practice on the tanks I cut up to get the gas cap from. Rather than add to this thread I will start a new one for the tank project.

And here's a picture of dad when he came out for a visit in 2008 on his 83 XSHS.....

...miss you Pops...

I hit the starter button and thankfully no grinding noises, she just rolled over about twice and started right up! I let it warm up a little and rode it around the neighborhood for about 7 miles (no plates or insurance yet) and noticed that the shift lever was too low, the upper triple clamp clamp bolt was loose (woops!) and I could only get the left flashers to work if I used the right one first. I was fairly pleased that was all that was wrong with it and it did pull well from just off idle and revved well to 6000 rpm. It would have revved higher but the bars get awful lively up there so that’s as far as I cared to go.

When I got back home I did some searching on the forum and found the flasher was likely a bad solder joint so I pulled the left control off and pulled it apart and sure enough one of the wires pulled right off. I re-soldered the faulty joint, cleaned and lubed everything and now all is well. I’m declaring it roadworthy and finished or at least as finished as any project gets. I am planning on getting plates and insurance this week and give her a proper shake down cruise this weekend.

The next item will be replacing the special tank with a standard tank and swapping the stock 1975 gas cap mount (the tank came without a cap) for a similar vintage Honda CB cap which I think looks better anyway and didn’t cost anything. I haven’t done much welding on material as thin as the tank so it should be a learning experience but I can get plenty of practice on the tanks I cut up to get the gas cap from. Rather than add to this thread I will start a new one for the tank project.

And here's a picture of dad when he came out for a visit in 2008 on his 83 XSHS.....

...miss you Pops...

Last edited:

Wow Mike - that old bike looks terrific - well done!

Your Dad sure looks happy on his then-newer XS650HS - I'll bet he is watching you and chuckling to himself at the fun you are having.

Ride safely and enjoy!

Pete

Your Dad sure looks happy on his then-newer XS650HS - I'll bet he is watching you and chuckling to himself at the fun you are having.

Ride safely and enjoy!

Pete

Last edited:

Nicely done Mike. I look forward to the next chapter of your nice old bike.

I almost forgot. After reading about how these bikes frequently have an issue with going into neutral at a stop with the engine running and having experienced it on all three of Dad's XS's I was pleasantly surprised when, after fiddling with the adjustment a few times, this one went into neutral when stopped in the driveway! Woo Hoo!!

You’re harshin’ on my buzz man! Let me at least enjoy my delusion until the weekends ride...

Let me at least enjoy my delusion until the weekends ride...

Last edited:

I really like the back story on this build. Well done Mike.

I took the bike for it’s first real ride a couple of weeks ago and it went MOSTLY good. It started and ran fine but the intermittent left turn signal issue came back. If I use the right signal first the left works fine but if I wait a while and then use the left it doesn’t work so I will be delving into that again, apparently the bad solder joint in the switch wasn’t the only problem. The handlebar bushings are also a bit floppy so I will try the washers between the bushings fix to try and tighten things up. It also turns out the right side cover emblem was glued on (which I never noticed) so when I got home the glue on the inside of the cover was still there but the emblem was gone.

The only REAL issue was with the rear brake. I had ridden about 25 miles and turned off to visit a shop I used to work at to see if anybody was there on a Saturday (there wasn’t) and when I turned off the main road the bike felt like it was down on power.(uh-oh) I pulled into the parking lot and the bike died and didn’t want to move when pushed and I also noticed that pungent “hot brake pad” smell and a few wisps of smoke from the rear pads. I put the bike on the centerstand and the front wheel turned fine but the rear was HOT and very stiff. I pulled the side cover off to get the tool kit and realized I had made a cardinal mistake, I never put the tool kit back on the bike!!! I should have known better than to take a 40 year old bike out on it’s maiden voyage without tools but never occurred to me in all the excitement of the first ride. Lesson learned.(again) I was weighing my options when I remembered I still had my pocketknife with me and with the 40 year old rubber brake line still on so it was no big loss if cutting the line got me back on the road. I cut the line and got a strong spurt of brake fluid and the brake released so I had found the problem if not the cause. I was planning to replace the rear line with braided stainless anyway so no harm, no foul. Poking around when I got home I found I had the rear master adjusted too tight and that’s what caused the brake to drag. All in all I was pleased, the bike ran fine, the new front brake works great and no major problems found other than the self-induced one.

The only REAL issue was with the rear brake. I had ridden about 25 miles and turned off to visit a shop I used to work at to see if anybody was there on a Saturday (there wasn’t) and when I turned off the main road the bike felt like it was down on power.(uh-oh) I pulled into the parking lot and the bike died and didn’t want to move when pushed and I also noticed that pungent “hot brake pad” smell and a few wisps of smoke from the rear pads. I put the bike on the centerstand and the front wheel turned fine but the rear was HOT and very stiff. I pulled the side cover off to get the tool kit and realized I had made a cardinal mistake, I never put the tool kit back on the bike!!! I should have known better than to take a 40 year old bike out on it’s maiden voyage without tools but never occurred to me in all the excitement of the first ride. Lesson learned.(again) I was weighing my options when I remembered I still had my pocketknife with me and with the 40 year old rubber brake line still on so it was no big loss if cutting the line got me back on the road. I cut the line and got a strong spurt of brake fluid and the brake released so I had found the problem if not the cause. I was planning to replace the rear line with braided stainless anyway so no harm, no foul. Poking around when I got home I found I had the rear master adjusted too tight and that’s what caused the brake to drag. All in all I was pleased, the bike ran fine, the new front brake works great and no major problems found other than the self-induced one.

Mike, I’m happy to hear your first outing was a fun adventure, problems and all, you persevered.

I had a couple of thoughts.

Re: your turn signal issue, bad grounds can cause wonky electrical issues, and handlebar switches are famous for ground issues.

And your rear brake. Have you ever had the caliper apart ? A lot of times dragging brakes are caused by corroded and stuck caliper pistons.

Keep up the good work. You’re getting there!

-Bob

I had a couple of thoughts.

Re: your turn signal issue, bad grounds can cause wonky electrical issues, and handlebar switches are famous for ground issues.

And your rear brake. Have you ever had the caliper apart ? A lot of times dragging brakes are caused by corroded and stuck caliper pistons.

Keep up the good work. You’re getting there!

-Bob

Mike: +1 on Mailman’s advice and another suggestion on turn signal woes:

Check the wire insulation right at the point where the signal wire goes inside the little threaded rod / stud that secures the turn signals onto their respective mounting points. On my ‘76, at least two of those studs had sharp metallic burrs right at the entrance holes. The insulation on one signal wire on one of those studs had worn through and was causing an intermittent short whenever I tried to use the LH turn signal.

All I had to do was disassemble each signal and use a bit of emery cloth to smooth the end of the hole and also repair the insulation on the signal wire - problem solved.

Pete

Check the wire insulation right at the point where the signal wire goes inside the little threaded rod / stud that secures the turn signals onto their respective mounting points. On my ‘76, at least two of those studs had sharp metallic burrs right at the entrance holes. The insulation on one signal wire on one of those studs had worn through and was causing an intermittent short whenever I tried to use the LH turn signal.

All I had to do was disassemble each signal and use a bit of emery cloth to smooth the end of the hole and also repair the insulation on the signal wire - problem solved.

Pete

Last edited:

I did rebuild the rear caliper, new piston and seals and it released fully when I cut the line so it seems to be working as it should.

Thanks for the suggestions gents, I'm hoping to have some time to poke around this weekend.

Thanks for the suggestions gents, I'm hoping to have some time to poke around this weekend.

did same thing, moved pedal stop bolt didn't set MC push rod to match, LOL ended up with custom strawberry colored rotor. Caliper got so hot it vaporized the brake fluid, problem "self repaired". Did do a full strip rebuild of the caliper, MC cuz it's never a bad idea.... already had a Teflon line on it.

Take pictures to share !I did rebuild the rear caliper, new piston and seals and it released fully when I cut the line so it seems to be working as it should.

Thanks for the suggestions gents, I'm hoping to have some time to poke around this weekend.

Sorry, I didn't take any pictures of the caliper rebuild.

I did disassemble and check the master cylinder and there were no problems there either so it was just the MC adjustment.(DOH!!)

I did disassemble and check the master cylinder and there were no problems there either so it was just the MC adjustment.(DOH!!)

Now, time for some more updates.

I replaced my original brake line with a braided stainless one from ANPlumbing (the old Earl’s) and VERY CAREFULLY adjusted the rear brake rod and now the rear brake works perfect. I thought the 14mm master might make it too wooden but I’m very pleased with the feel and won’t be making any more changes to the brakes.

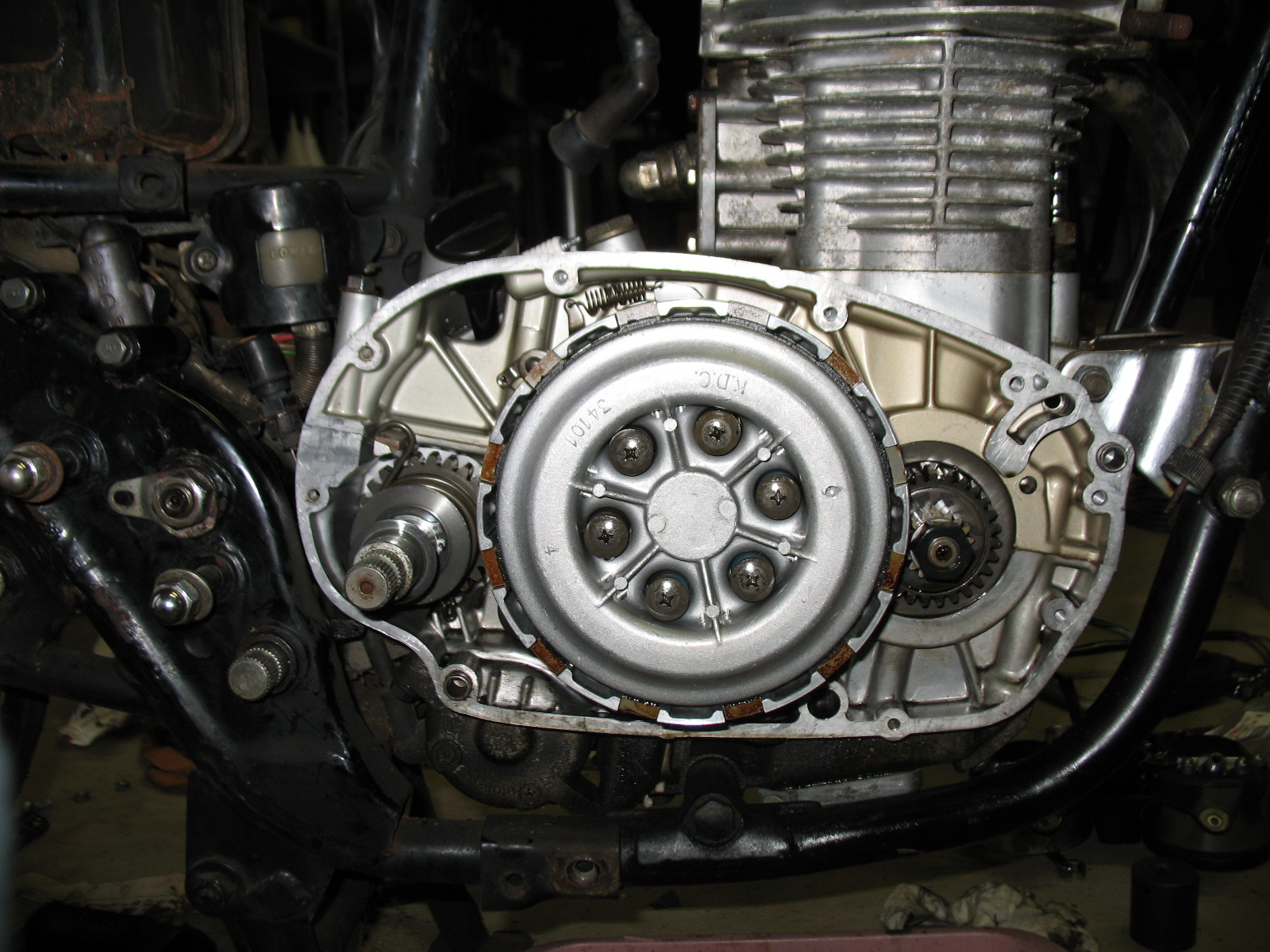

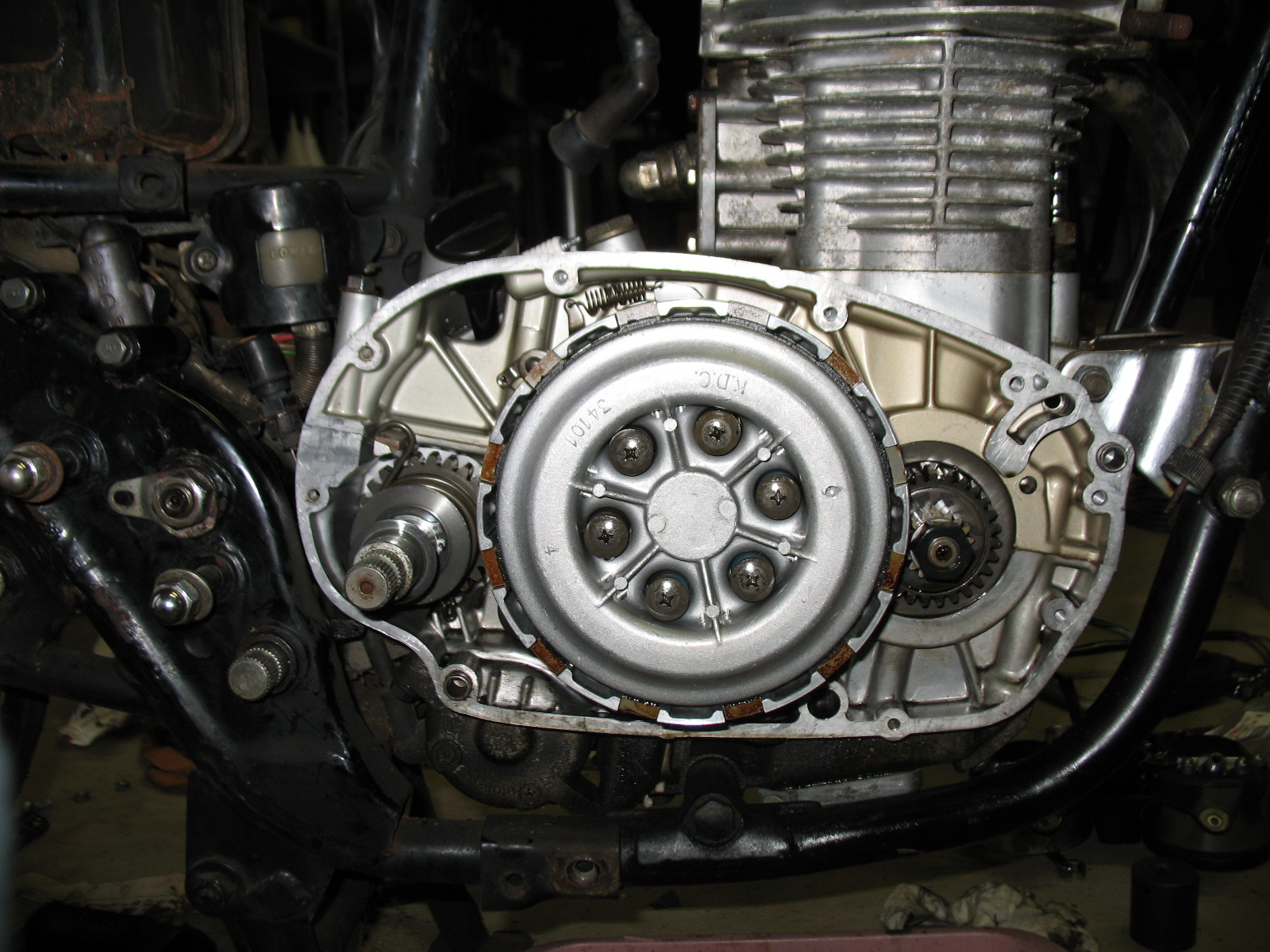

BUT, on a couple of rides I noticed just a hint of clutch slipping in 5th going up hills so I also replaced the original clutch springs with some HD Vesrah springs while I had the bike in the basement for the brake line. Clutch slipping solved.

I have ridden it to work a couple of times, maybe 200 miles total, and figured I was done fixing things until last Friday. As I was pulling off the highway and reached the bottom of the off ramp it sputtered and died. I tried the starter button and just got a click. I tried kicking it and it fired up for a few seconds and died again. The instrument lights, and all the other lights for that matter, were pretty dim so I assumed I probably had a charging issue and ended up pushing the bike about 1-1/4 miles to work where I had access to some tools and more importantly a DMM. After some poking around it was pretty clear it WAS a charging issue as the battery was dead (9.8V) and the rotor measured 0.7 ohms so definitely a dead rotor. I was surprised as after first bringing the bike back to life it had 14.5 volts at the battery so I assumed the charging system was in decent condition. I charged the battery up during the day and rode the beasty 36 miles to home with the headlight disconnected and the battery still had a pretty good charge when I got there so I could have gone quite a bit further should anybody have wondered how far you can get on a dead charging system.

I looked through Dad’s stash of old parts and found five rotors, three of which measured above 5 ohms and were in useable condition. Rather than just replace the rotor I did some poking around the forum and there was a lot of advice to check voltage at the brown wire and check/clean connections before just replacing the rotor and, sure enough, the voltage was off by about 1 volt so time to clean some connections and the ignition switch. The first connector I checked was at the voltage regulator and the male connector on the red wire had pretty much turned to dust and the others were pretty ugly. (The other things in the pic are the bent up paperclips I used to remove the connectors from the plug, one for male and one for female.)

After replacing the connectors on the red wire and cleaning up pretty much every connector on the bike plus the ignition switch the voltage difference between the red and brown wire is less than 0.1V so all should be well. Even if the ignition switch contacts weren’t all that bad it was still worth cleaning it as the grease had turned to tar and now it works SOOOO much better. I put the rotor in the lathe and polished up the contacts real “purdy” and resistance is 5.3 so I should be good to go. I’m in process of putting everything back together and hope to have it finished shortly, maybe tonight if the stars align.

I replaced my original brake line with a braided stainless one from ANPlumbing (the old Earl’s) and VERY CAREFULLY adjusted the rear brake rod and now the rear brake works perfect. I thought the 14mm master might make it too wooden but I’m very pleased with the feel and won’t be making any more changes to the brakes.

BUT, on a couple of rides I noticed just a hint of clutch slipping in 5th going up hills so I also replaced the original clutch springs with some HD Vesrah springs while I had the bike in the basement for the brake line. Clutch slipping solved.

I have ridden it to work a couple of times, maybe 200 miles total, and figured I was done fixing things until last Friday. As I was pulling off the highway and reached the bottom of the off ramp it sputtered and died. I tried the starter button and just got a click. I tried kicking it and it fired up for a few seconds and died again. The instrument lights, and all the other lights for that matter, were pretty dim so I assumed I probably had a charging issue and ended up pushing the bike about 1-1/4 miles to work where I had access to some tools and more importantly a DMM. After some poking around it was pretty clear it WAS a charging issue as the battery was dead (9.8V) and the rotor measured 0.7 ohms so definitely a dead rotor. I was surprised as after first bringing the bike back to life it had 14.5 volts at the battery so I assumed the charging system was in decent condition. I charged the battery up during the day and rode the beasty 36 miles to home with the headlight disconnected and the battery still had a pretty good charge when I got there so I could have gone quite a bit further should anybody have wondered how far you can get on a dead charging system.

I looked through Dad’s stash of old parts and found five rotors, three of which measured above 5 ohms and were in useable condition. Rather than just replace the rotor I did some poking around the forum and there was a lot of advice to check voltage at the brown wire and check/clean connections before just replacing the rotor and, sure enough, the voltage was off by about 1 volt so time to clean some connections and the ignition switch. The first connector I checked was at the voltage regulator and the male connector on the red wire had pretty much turned to dust and the others were pretty ugly. (The other things in the pic are the bent up paperclips I used to remove the connectors from the plug, one for male and one for female.)

After replacing the connectors on the red wire and cleaning up pretty much every connector on the bike plus the ignition switch the voltage difference between the red and brown wire is less than 0.1V so all should be well. Even if the ignition switch contacts weren’t all that bad it was still worth cleaning it as the grease had turned to tar and now it works SOOOO much better. I put the rotor in the lathe and polished up the contacts real “purdy” and resistance is 5.3 so I should be good to go. I’m in process of putting everything back together and hope to have it finished shortly, maybe tonight if the stars align.

Last edited:

P.S. it runs and starts great and I'm getting about 51 mpg in mixed driving so pleased with that.

Yes, that reg/rec plug is in a bad spot on the '80-on models, right next to the battery. It's subjected to battery acid and/or battery acid fumes, and it takes a beating. Mine was corroded up pretty good with a couple of bad connectors in it too.

I liked your backstory. Building the bike for Dad even though he passed is a good way to show your love for your Dad. Having the bike you relive times with your Dad.

My Dad passed when I was young. I don't have much to remember him by. A Zippo lighter with a guy fly fishing on the front.

Great thread on the rebuild.

Leo

My Dad passed when I was young. I don't have much to remember him by. A Zippo lighter with a guy fly fishing on the front.

Great thread on the rebuild.

Leo

Similar threads

- Replies

- 26

- Views

- 2K