That 11° sounds OK.

It leaves about 25° for dog engagement, better than 1/2 the action.

0.008" (0.2mm) endplay sounds a bit loose. Haven't seen any spec for that. That's when I'd fall back to my ol' thresholds of 0.002" (0.05mm) ideal, 0.004" (0.1mm) service limit.

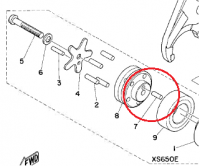

The outboard end of the shiftdrum *can* be removed without splitting the cases.

http://www.xs650.com/threads/bearing-id-help.54116/

Post #79.

http://www.xs650.com/threads/1981-xs650-sh-restoration.53833/page-4#post-581707

Check the condition of the inner edge of the "C" stopper plate, and the mating slot in the shiftdrum end. Recommend a new bolt in there...

It leaves about 25° for dog engagement, better than 1/2 the action.

0.008" (0.2mm) endplay sounds a bit loose. Haven't seen any spec for that. That's when I'd fall back to my ol' thresholds of 0.002" (0.05mm) ideal, 0.004" (0.1mm) service limit.

The outboard end of the shiftdrum *can* be removed without splitting the cases.

http://www.xs650.com/threads/bearing-id-help.54116/

Post #79.

http://www.xs650.com/threads/1981-xs650-sh-restoration.53833/page-4#post-581707

Check the condition of the inner edge of the "C" stopper plate, and the mating slot in the shiftdrum end. Recommend a new bolt in there...

Last edited: