'70-'83 XS650 Rear Brake Shoes

Drum diameter = 180mm

Shoe Diameter = 179mm

Shoe Width = 30mm

Yamaha OEM part #'s

148-25330-00

156-25330-00

168-25330-00

256-25330-00

447-25330-00

447-25330-01

4L0-25330-00

4L0-W2536-00

5R3-W253E-00

5R3-W2536-00.

Some aftermarket offerings:

Vesrah VB-225

EBC-514

MikesXS 29-3211

SOK-206 4L0-00 168

2FastMoto: # 2FM-09-2111GS

Replacing brake shoes.

No-brainer, right?

Perform the service routine on rear drum brake servicing, written by 5twins:

http://www.xs650.com/threads/how-difficult-is-it-to-replace-the-rear-drum-brakes.25632/

Then, just plop the new shoes right in there, and go riding.

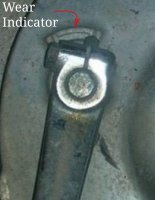

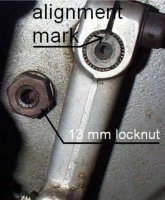

Well, some of the aftermarket shoes could use a little closer inspection...

Drum diameter = 180mm

Shoe Diameter = 179mm

Shoe Width = 30mm

Yamaha OEM part #'s

148-25330-00

156-25330-00

168-25330-00

256-25330-00

447-25330-00

447-25330-01

4L0-25330-00

4L0-W2536-00

5R3-W253E-00

5R3-W2536-00.

Some aftermarket offerings:

Vesrah VB-225

EBC-514

MikesXS 29-3211

SOK-206 4L0-00 168

2FastMoto: # 2FM-09-2111GS

Replacing brake shoes.

No-brainer, right?

Perform the service routine on rear drum brake servicing, written by 5twins:

http://www.xs650.com/threads/how-difficult-is-it-to-replace-the-rear-drum-brakes.25632/

Then, just plop the new shoes right in there, and go riding.

Well, some of the aftermarket shoes could use a little closer inspection...

Last edited: