Good Plan. Road test is soon. My fuel tank situation (and a dog) is preventing further testing todaywould give it a quick road test as is to see how well the brake works now, then "fix" it and road test again. Back to back tests, so to speak.

-RT

Good Plan. Road test is soon. My fuel tank situation (and a dog) is preventing further testing todaywould give it a quick road test as is to see how well the brake works now, then "fix" it and road test again. Back to back tests, so to speak.

2m, I wus thinking of turning a mandrel out of a bolt or such to clean up the pivot on the aftermarket shoes. Machine it to match the pivot pin on the brake plate, cut some angled slots with the cut off wheel in the dremel so it will act as a cutter. Figured I can chuck the mandrel /cutter in the lathe, clamp a shoe to the tool post and feed it in. See any holes in that plan?

... I am a lot more concerned about front brake performance compared to rear...

I just checked the brake rods on my later machines and they are M6 x 1.0, so that Virago wing nut should fit. The early brake rods must be different?

So, it seems another obscure factoid has come to light, lol.

Is there enough meat to drill and tap for M8-1.00

Just to confirm, your XS1 brake rod is an 8mm diameter?

7mmAny XS2 members want to measure theirs?

Long as you are peering down a rabbit hole, a dual leading shoe conversion ...

...I'm a rude, crude, lazy dude...

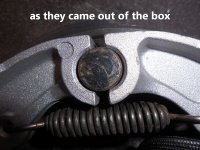

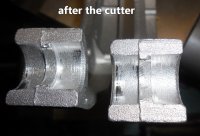

...Think this should be a nice improvement over the "out of the box" fit...

Viragos offer some other nice plug-and-play items for our 650's - aluminum handlebar clamps (easily polished) and signal light lenses and trim rings that swap directly for OEM 650 parts.Drilled and tapped the Virago adjuster to M7x1.0. The original adjuster is steel. This adjuster is chrome plated pot-metal (Zymak). The tiny pieces of casting flash allowed the 3-jaw to hold it without slipping.

View attachment 137745

And, a little bling, in a sea of patina.

View attachment 137746

A hattip to 5twins for this Virago adjuster idea...

...2M how far have you gotten your full floating design?