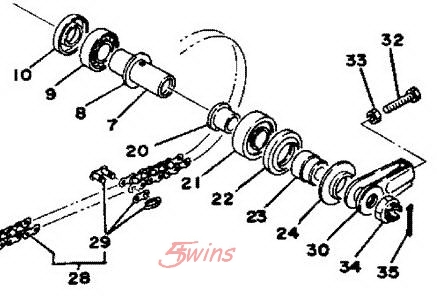

NOPE there is an insert inside the ball bearing inner race.

Part #20

Part #20

... soon I was getting the kind of stares that make you check that your fly is indeed up.

...so it's ready for sandblasting...

...What if anything should be done about this particular spot showing aggressive rust damage? Would it be enough to just grind that rust off, or should I have this area reinforced?

... Been trying to figure out if this hook has any significance before I cut it off- I couldn't find anything in the manuals, wanted to be sure before I cut it off.

... I want to replace the tail with a flared hoop for a clean look and thinking to cut here, halfway between the welded supports going to swingarm so that when I have the hoop welded in, the swingarm support adds extra strength by having both the hoop end and frame end being welded atop it. Good idea?

Hi DQG,

80 grit will be ok, just don't go apeshit with it, eh?

At least, not until you've seen what it will do.

For cleaning up the frame tubes in the photos, you could also try using a strip of 80 grit emery tape.

1" wide cloth tape, abrasive on one side, comes in a roll, tear off what you'll need.

I use a mebbe 30" long strip holding an end in each hand, cleans up not quite half way around a tube as you pull it back and forth.

I actually was thinking of doing what you suggested with the tape- buying a roll of emery paper, wrap it around the tubes and just go back and forth with it. Evenly sanded, right to the diameter of the tubes. Seems like a no-brainer to me.

those ain't cracks they's aluminum casting shrinkage lines, you'll find em all over the cases if you start looking.