Glad I could help.Thanks for the suggestions!

-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

79 Special II RestoCustom "Doomy"

- Thread starter member28833

- Start date

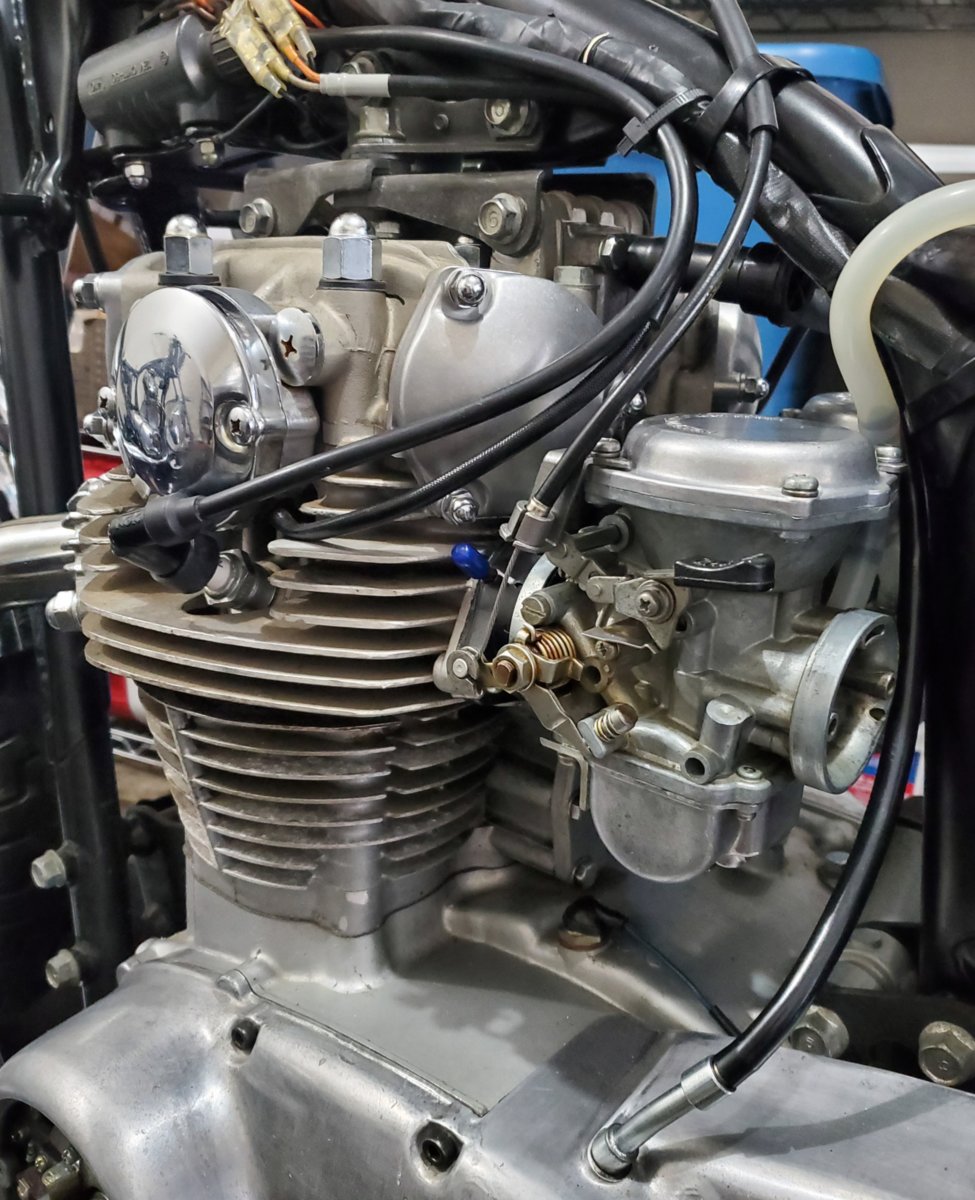

"Doomy" was last parked in a "barely proven" but running condition. Before the re start there were a few more things to make progress on such as those carb boots, carb fuel lines, final routing of cables and lines and such.

More points timing adjustments, etc.. which also meant a more permanent mounting of the battery before a second start up.

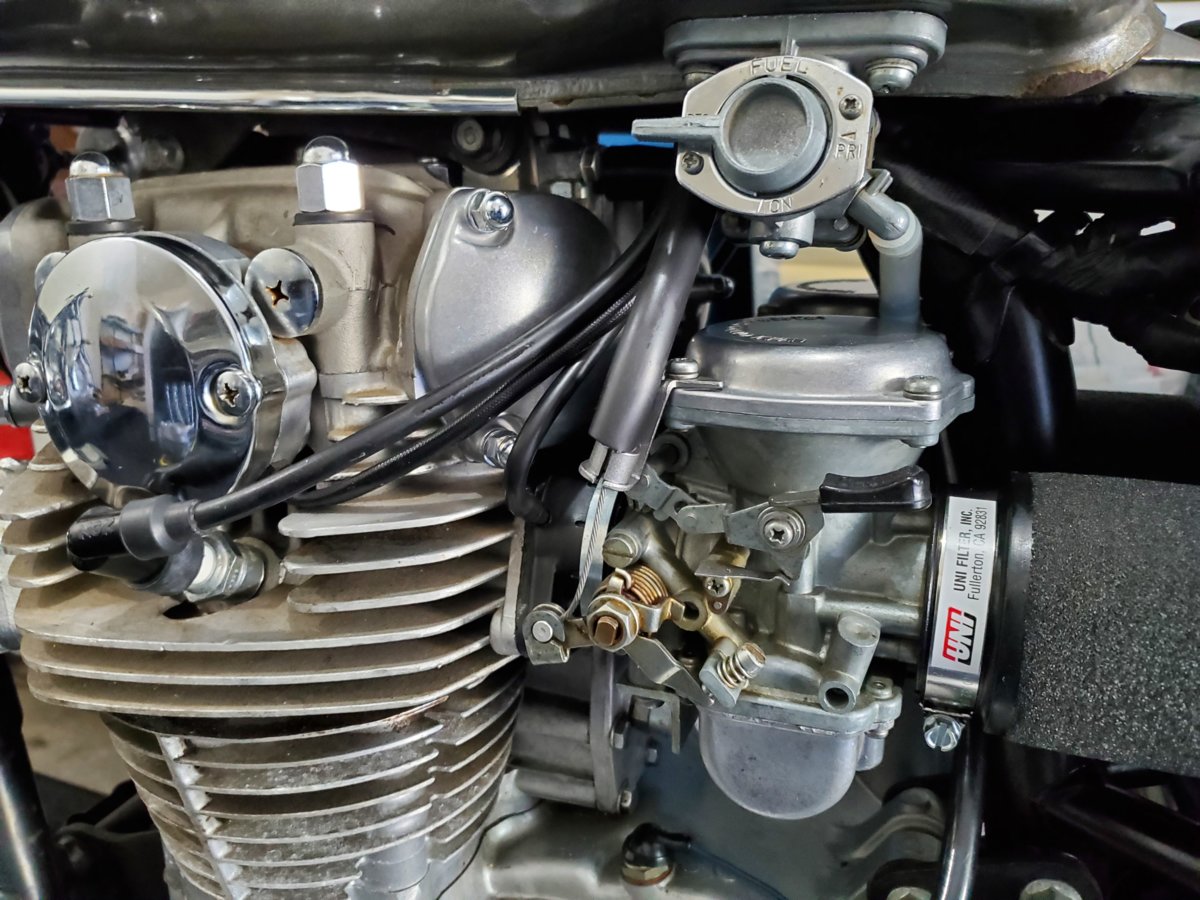

Those BS38's do just barely sneak into place and routing the fuel line (spliced) and clutch cable between the frame and carb stay was very tight but is now perfecto !

carbs checked out well so far.

carbs checked out well so far.

And 5twins was correct attempts to locate the carb clamp screws underneath just doesn't quite happen so I angled em back nicely out of sight.

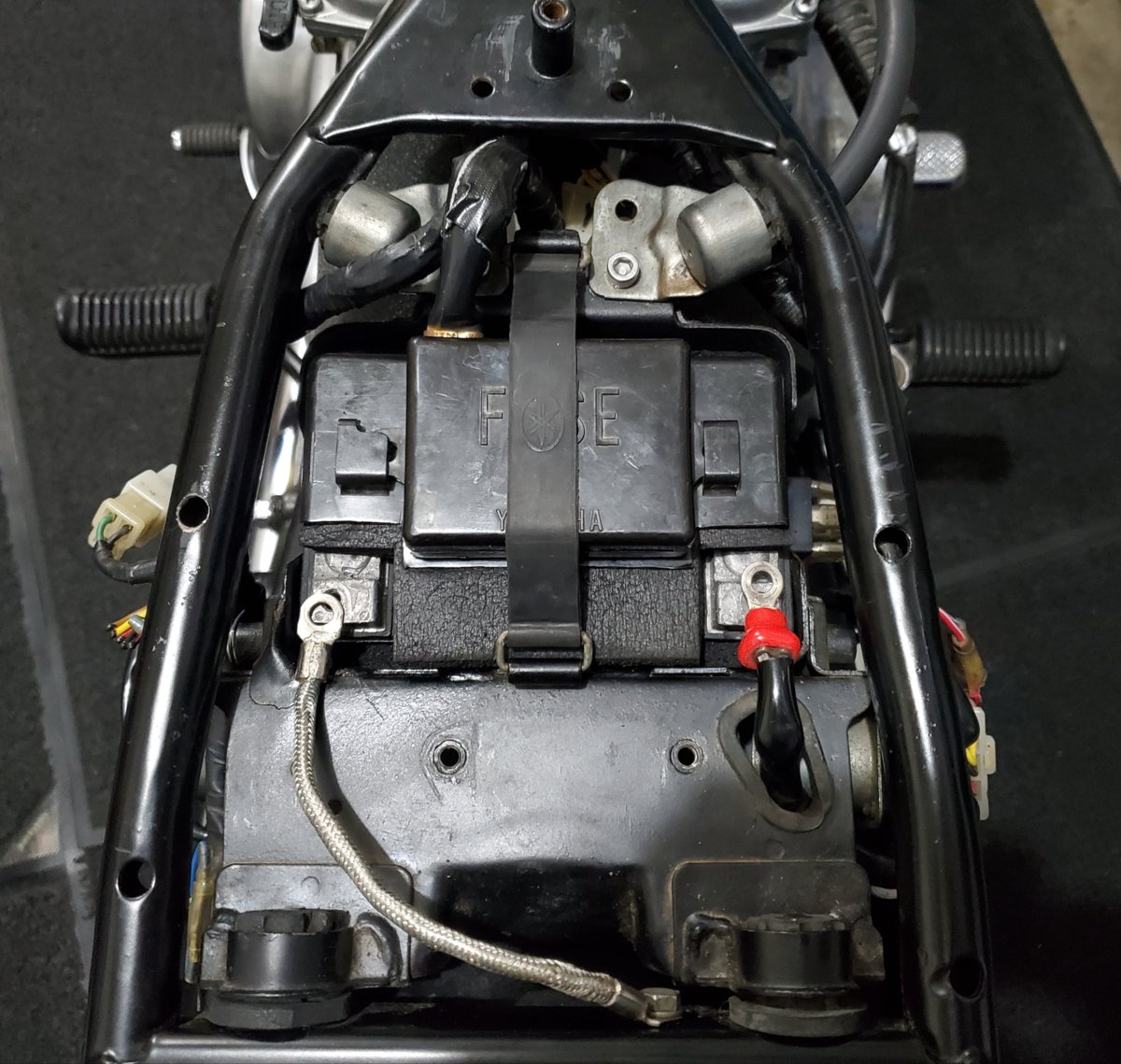

I made a real spiffy battery tray floor out of plastic and stuffed that battery in there surrounded with 1/2" thick foam and that battery is Snug and vibration proof!

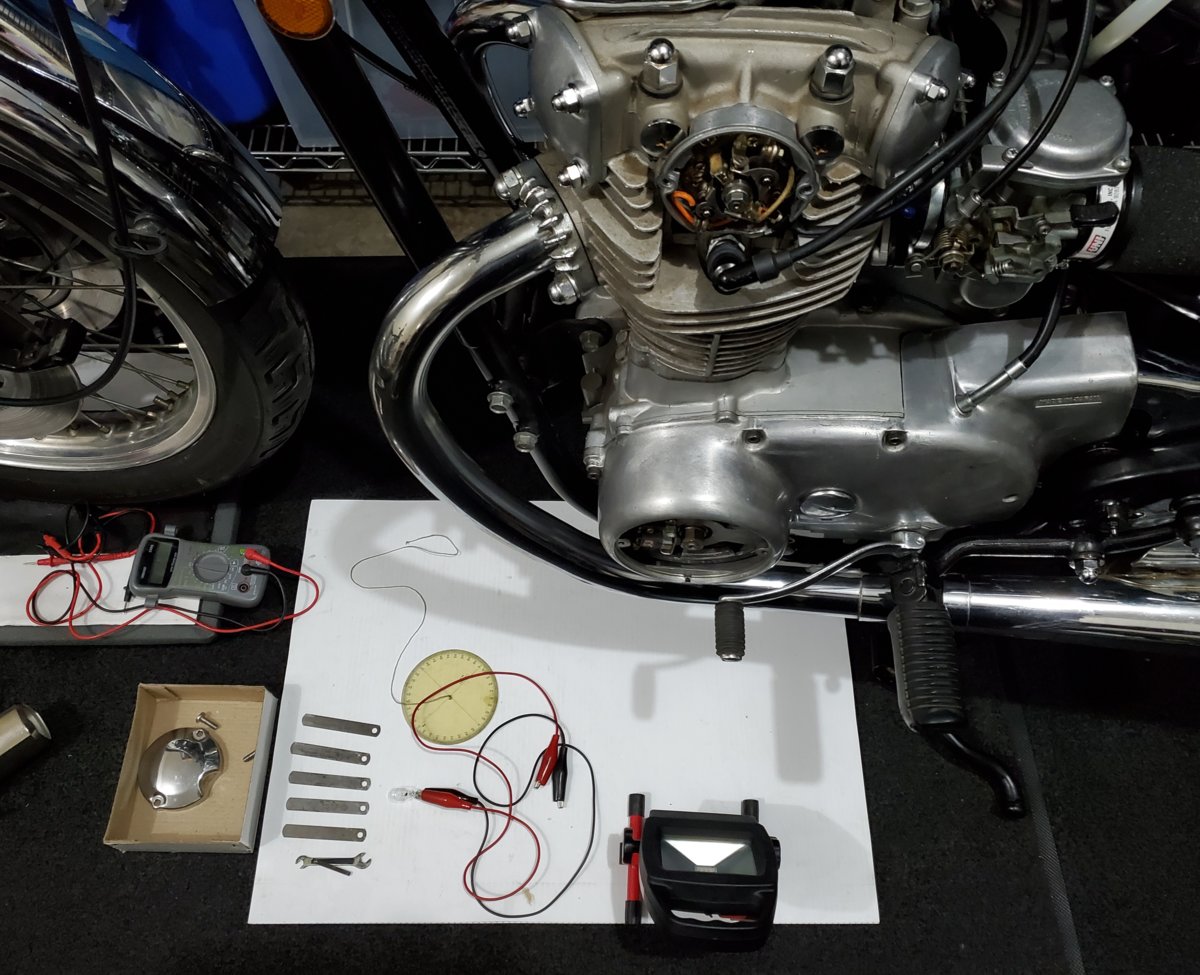

So I have attempted to reset my points timing and am in the process of figuring out how to hook up my small 12v lamp bulb as a tool to check timing with.

I Face it, it's just too hard see and trust luck.

That's all there is for an update. It's cold and rainy out but the next attempt to run this XS is possibly tomorrow.

Take care everybody! The world got real crazy for all of us. Many priorities right now out weigh my XS play time...

-RT

More points timing adjustments, etc.. which also meant a more permanent mounting of the battery before a second start up.

Those BS38's do just barely sneak into place and routing the fuel line (spliced) and clutch cable between the frame and carb stay was very tight but is now perfecto !

And 5twins was correct attempts to locate the carb clamp screws underneath just doesn't quite happen so I angled em back nicely out of sight.

I made a real spiffy battery tray floor out of plastic and stuffed that battery in there surrounded with 1/2" thick foam and that battery is Snug and vibration proof!

So I have attempted to reset my points timing and am in the process of figuring out how to hook up my small 12v lamp bulb as a tool to check timing with.

I Face it, it's just too hard see and trust luck.

That's all there is for an update. It's cold and rainy out but the next attempt to run this XS is possibly tomorrow.

Take care everybody! The world got real crazy for all of us. Many priorities right now out weigh my XS play time...

-RT

Attachments

Your usual nice work Randy! I like the carb manifolds. So does your gas tank only have one fuel tap?

Yes, Left only 81 Special tank with one nice original cleaned vacuum petcock.

There is a Standard tank on my shelf that utilized the twin 78E petcocks.

Now if that Standard tank were Silver ? I just may switch tanks in the future..

There is a Standard tank on my shelf that utilized the twin 78E petcocks.

Now if that Standard tank were Silver ? I just may switch tanks in the future..

Now that the battery is back in place which is back on track for more running, I needed to address the switch grounds thru the "black chrome" handle bar coating. Simple 10 minute job.

Right...

Well the left switch was straight forward to do and I upgraded the screws to longer new screws which bite threads all the way to the bottom. Marked the bar and filed a connection there and back on.

The Right switch is a MikesXS switch. Upon attempting to re bend the ground tab into position I found it too easy to bend? Looking closer in there it's obvious the tab is very near broken. Now it gets interesting. Upon disassembly it becomes apparent that the tab is "fatigue" broken in the bend. Broken even before being anodized. Broken before being assembled and sold. Go Figure..

closer in there it's obvious the tab is very near broken. Now it gets interesting. Upon disassembly it becomes apparent that the tab is "fatigue" broken in the bend. Broken even before being anodized. Broken before being assembled and sold. Go Figure..

Fortunately, I have a 78 series MikesXS switch in my spare stuff and that contact tab is fine so that was an "easy" and lucky fix.

Now after all this there is happily good news ! My turn signals blink like champions, engine off even.

Well, that used up my time today.

Unfortunately, no restart of the engine..

-RT

Right...

Well the left switch was straight forward to do and I upgraded the screws to longer new screws which bite threads all the way to the bottom. Marked the bar and filed a connection there and back on.

The Right switch is a MikesXS switch. Upon attempting to re bend the ground tab into position I found it too easy to bend? Looking

Fortunately, I have a 78 series MikesXS switch in my spare stuff and that contact tab is fine so that was an "easy" and lucky fix.

Now after all this there is happily good news ! My turn signals blink like champions, engine off even.

Well, that used up my time today.

Unfortunately, no restart of the engine..

-RT

Attachments

The switch housings grounding to, and transferring the ground through the handlebars has nothing to do with the turn signal switch. That ground transfer through the bars is all about providing a ground for the start button. The turn signal switch grounds through the black ground wire running from the left control assembly into the headlight. So, don't pat yourself on the back yet, not until you try the start button, lol.

Oops, yes. I remember that now.That ground transfer through the bars is all about providing a ground for the start button.

That does make sense as it seems the po did spend time at the starter solenoid and actually replaced it too. The solenoid seems quite healthy. I did find the starter connection to be corroded and not able to function. That repair is later.

One interesting mistake I did find of my prior start up was that I did not connect the black wire out of the main harness to the left coil post (ground) like factory.

Anyway, one more test run and I'll put the tank on hopefully.

Last edited:

Ignition is set ! See the covers are on.

Test run #2 was a full on success. No oil leak. Not even a drop anywhere yet.

Static timing changes with the aid of the 12V bulb allowed me to even out the timing differences between the two sides almost perfectly. Although after reading in other threads about slightly retarding the ignition and going for that, my timing proves out with the timing light to be close to retarded at idle, the timing advances immediately with throttle. I have always set the timing more advanced on the other XS's so this was a personal test to do.

Didn't even adjust the mixture screws yet. It purred.

Tested the clutch and transmission. All a Go.

Cam chain etc.. good.

Decided to see how low in rpm it would idle, kept backing off the idle screw a little more thinking that would kill it ? Nope, It must have been 600 before it died.

Slowest and nicest pulses I've ever heard out of an XS.

So the engine is ready to road test. The bike needs the body mounted. Side covers are not done. Seat is not done. No tail light yet. No front brake lines delivered yet.

I'll stop carrying on about the mechanical tuning here and try to pretty it up for an anticipated road test.

Attachments

Last edited:

View attachment 163792 View attachment 163787

Ignition is set ! See the covers are on.

Test run #2 was a full on success. No oil leak. Not even a drop anywhere yet.

Static timing changes with the aid of the 12V bulb allowed me to even out the timing differences between the two sides almost perfectly. Although after reading in other threads about slightly retarding the ignition and going for that, my timing proves out with the timing light to be close to retarded at idle, the timing advances immediately with throttle. I have always set the timing more advanced on the other XS's so this was a personal test to do.

Didn't even adjust the mixture screws yet. It purred.

Tested the clutch and transmission. All a Go.

Cam chain etc.. good.

Decided to see how low in rpm it would idle, kept backing off the idle screw a little more thinking that would kill it ? Nope, It must have been 600 before it died.

Slowest and nicest pulses I've ever heard out of an XS.

So the engine is ready to road test. The bike needs the body mounted. Side covers are not done. Seat is not done. No tail light yet. No front brake lines delivered yet.

I'll stop carrying on about the mechanical tuning here and try to pretty it up for an anticipated road test.

Sounds good Randy! This bike is looking like a keeper, is that your plan, or will it be sold to make room for the next one?

Plan ? Good one.. the world got so crazy that I live day to day. Why plan lol..Sounds good Randy! This bike is looking like a keeper, is that your plan, or will it be sold to make room for the next one?

Hell the unemployment issues and there of have directly impacted my own family hard. So even if It rides out great ? IDK what to do anymore..

Plan ? Good one.. the world got so crazy that I live day to day. Why plan lol..

Hell the unemployment issues and there of have directly impacted my own family hard. So even if It rides out great ? IDK what to do anymore..

It’s a one day at a time world for us all right now brother. Hang in there!

Rode it

No front brakes. No seat. No tail light.

Runs real good ! Sounds just great. Nice and even running of the cylinders. Great clutch and transmission (3 gears so far) fantastic rear brake.

VRrooom!

So this project is still moving forward. I gotta find more stuff

No front brakes. No seat. No tail light.

Runs real good ! Sounds just great. Nice and even running of the cylinders. Great clutch and transmission (3 gears so far) fantastic rear brake.

VRrooom!

So this project is still moving forward. I gotta find more stuff

Attachments

Atta boy Randy!

Rode it

No front brakes. No seat. No tail light.

Runs real good ! Sounds just great. Nice and even running of the cylinders. Great clutch and transmission (3 gears so far) fantastic rear brake.

VRrooom!

So this project is still moving forward. I gotta find more stuff

View attachment 164111 View attachment 164114

Looks really nice, but why no front brakes Randy?

no worries, the calipers and pads and such are waiting dry.

Lines are delayed a while.

Lines are delayed a while.

Next hurdle is this $50 solo seat.

Too flat in the rear as it hits the fender out there just past the tail light wiring junction.

So it must be bent somehow.

First attempt found the plastic melting point but the seat tail area was tough and sprang back.(hot to handle)

Attempt two will hopefully succeed so I can adapt stock XS Aluminum trim onto this Chiseat.

Too flat in the rear as it hits the fender out there just past the tail light wiring junction.

So it must be bent somehow.

First attempt found the plastic melting point but the seat tail area was tough and sprang back.(hot to handle)

Attempt two will hopefully succeed so I can adapt stock XS Aluminum trim onto this Chiseat.

Attachments

Excellent write up Randy - meticulous work, candid instructional detail and engaging illustration I'm putting you up with Mailman as a go to reference source. Well done!

Chinese brake lines did show up. Not a bolt on mod. I ordered two (twin) 90 cm black lines. Your two choices when ordering are length in 10 cm increments and color.

Firstly the banjo bodies are almost .1" wider across the sealing surfaces requiring a different double banjo bolt than I previously found for doubling up original hoses. Friday I found some nearly usable Honda brake banjo bolt hardware. I will face them down in a lathe just slightly as those are slightly too long for the Yamaha threaded holes in the master cylinder and the calipers as well. What a pain so far.

Now the 90cm lines. As pics show my plan is reasonable however the lines (which measure about 93cm) are slightly too long. The 28° banjo heads are both in the same orientation. I would need different orientation, say one rotated 90° for a good fitment. Twisting these braided lines is difficult and really just creates a arc or loop in the line. So twisting them is a no go.

Its been a long time waiting for this fit attempt and I am disappointed.

I need to find a local source to either buy hands on or make lines on demand for need.

Firstly the banjo bodies are almost .1" wider across the sealing surfaces requiring a different double banjo bolt than I previously found for doubling up original hoses. Friday I found some nearly usable Honda brake banjo bolt hardware. I will face them down in a lathe just slightly as those are slightly too long for the Yamaha threaded holes in the master cylinder and the calipers as well. What a pain so far.

Now the 90cm lines. As pics show my plan is reasonable however the lines (which measure about 93cm) are slightly too long. The 28° banjo heads are both in the same orientation. I would need different orientation, say one rotated 90° for a good fitment. Twisting these braided lines is difficult and really just creates a arc or loop in the line. So twisting them is a no go.

Its been a long time waiting for this fit attempt and I am disappointed.

I need to find a local source to either buy hands on or make lines on demand for need.

Attachments

I like the direction you’re going, sorry to hear they aren’t working out for you.

You might want to explore build your own brake line kits. Alternately I’ve bought brake lines from Galfer and I’ve seen nice custom lines from HEL performance. Unfortunately none of those options are nearly as inexpensive as your Chinese lines.

You might want to explore build your own brake line kits. Alternately I’ve bought brake lines from Galfer and I’ve seen nice custom lines from HEL performance. Unfortunately none of those options are nearly as inexpensive as your Chinese lines.

Similar threads

- Replies

- 2

- Views

- 1K

- Replies

- 31

- Views

- 4K