happychappy

XS650 Member

thanks for all the help. I read a couple of threads including the troubleshooting guide.

Testing the coil:

1; Using the lowest scale on the meter, measure the resistance between the primary terminals with the wires removed. 4.4

2; Using the highest scale on the meter, measure between one of the primary terminals and the center core of the coil. Should be infinite resistance. OPEN

3; Measure between one of the primary terminals and one of the plug wire terminals. Should be infinite resistance. OPEN

4; Measure between one of the plug wire terminals and the core of the coil. Should be infinite resistance OPEN

5; Measure from one plug terminal to the other. Should be 15,000 to 20,000 Ohms.

Meter set to 200k

Without the caps 20.9

With caps 30

Testing the PAMCO

Battery 12.36

1, Use a voltmeter and check for battery voltage on each of the red/white wires with the key and kill switch are turned on. 12.36

2, The dual output coil has to have both spark plug wires connected to a spark plug at all times. Yes

3, To test for spark, connect one of the spark plug wires to a spark plug that is grounded to the engine. Used spark tool no spark

To test for spark without having to turn the engine over, do this procedure:

1. Remove the PAMCO rotor.

2. Remove the locating pin in the advance rod.

3. Reinstall the rotor, but without the pin.

4. Replace the nut holding the rotor on loosely. This will allow you to spin the rotor to produce a spark without having to turn the engine over.

5, Connect one of the spark plug wires to a spark plug that is grounded to the engine, but not installed in the engine.

6, Make sure that the other spark plug wire is connected to a spark plug in the engine.

7. Turn on the ignition switch and the kill switch.

8, Spin the rotor while looking at the gap in the spark plug for a spark.

9, Turn off the kill switch and the ignition switch.

1) Resistance between primary terminals:4.4

2) Resistance between primary terminals and core (the exposed metal by the mounting holes) pen

pen

3) Resistance between primary terminal and plug wire: open

4) Resistance between plug wire and core: open

5) Resistance between Plug wire and terminals:

Meter set to 200k

Without the caps 20.9

With caps 30

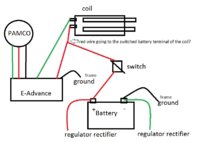

PAMCO testing: (everything hooked up, kill switch/key on)

Battery: 12.36

Kill switch, both terminals: 12.3

Red wire, Sensor: 11.51

Green wire, Sensor: .04/0 this fluctuates when spinning the rotor.

Black wire, sensor: 0

Red wire, Coil: 12.3

Green Wire, Coil: 12.32

Black wire, Coil:0

referenced these two treads.

http://www.xs650.com/threads/pamco-e-advance-no-spark-continuity-issues.40127/

and

http://www.xs650.com/threads/pamco-ignition.46859/

Testing the coil:

1; Using the lowest scale on the meter, measure the resistance between the primary terminals with the wires removed. 4.4

2; Using the highest scale on the meter, measure between one of the primary terminals and the center core of the coil. Should be infinite resistance. OPEN

3; Measure between one of the primary terminals and one of the plug wire terminals. Should be infinite resistance. OPEN

4; Measure between one of the plug wire terminals and the core of the coil. Should be infinite resistance OPEN

5; Measure from one plug terminal to the other. Should be 15,000 to 20,000 Ohms.

Meter set to 200k

Without the caps 20.9

With caps 30

Testing the PAMCO

Battery 12.36

1, Use a voltmeter and check for battery voltage on each of the red/white wires with the key and kill switch are turned on. 12.36

2, The dual output coil has to have both spark plug wires connected to a spark plug at all times. Yes

3, To test for spark, connect one of the spark plug wires to a spark plug that is grounded to the engine. Used spark tool no spark

To test for spark without having to turn the engine over, do this procedure:

1. Remove the PAMCO rotor.

2. Remove the locating pin in the advance rod.

3. Reinstall the rotor, but without the pin.

4. Replace the nut holding the rotor on loosely. This will allow you to spin the rotor to produce a spark without having to turn the engine over.

5, Connect one of the spark plug wires to a spark plug that is grounded to the engine, but not installed in the engine.

6, Make sure that the other spark plug wire is connected to a spark plug in the engine.

7. Turn on the ignition switch and the kill switch.

8, Spin the rotor while looking at the gap in the spark plug for a spark.

9, Turn off the kill switch and the ignition switch.

1) Resistance between primary terminals:4.4

2) Resistance between primary terminals and core (the exposed metal by the mounting holes)

3) Resistance between primary terminal and plug wire: open

4) Resistance between plug wire and core: open

5) Resistance between Plug wire and terminals:

Meter set to 200k

Without the caps 20.9

With caps 30

PAMCO testing: (everything hooked up, kill switch/key on)

Battery: 12.36

Kill switch, both terminals: 12.3

Red wire, Sensor: 11.51

Green wire, Sensor: .04/0 this fluctuates when spinning the rotor.

Black wire, sensor: 0

Red wire, Coil: 12.3

Green Wire, Coil: 12.32

Black wire, Coil:0

referenced these two treads.

http://www.xs650.com/threads/pamco-e-advance-no-spark-continuity-issues.40127/

and

http://www.xs650.com/threads/pamco-ignition.46859/

Attachments

Last edited: