plane_ben

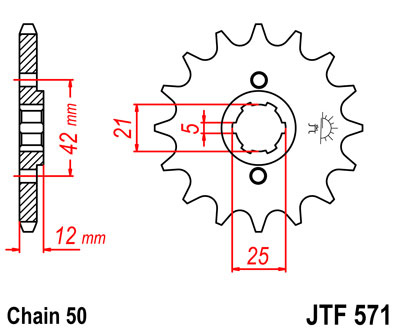

XS650 Junkie

I'm in need of gearing down my 23" rear tire. I used the stock gearing in a 17/32 combo and it's pretty tall. Nice on the highway, but too tall for around town where it is normally ridden. Can't go bigger on the rear sprocket because of the fender clearance. So I want to drop the front sprocket one tooth to a 16. Looking at mikesxs I see they sell a 530 pitch 16 tooth front for an XS400. Looks like the same output shaft splines in the picture. Can anybody confirm this will fit an XS650 or not? I've tried looking up cross use information on the web, but can't seem to find the right combination of key words. Asked around all the local bike shops Saturday, no-one had an XS counter sprocket in stock so I couldn't compare. Just would like some first hand knowledge before I order one up. Thanks

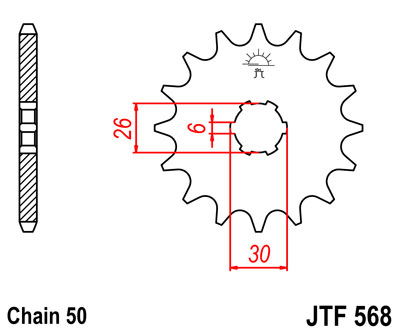

So, I bought a 530/16 tooth counter sprocket for a Honda and started machining. Going to push the hole out some more, but ran out of time today. Next will be turning down the Yamaha sprocket. I need to make a shaft I can put the sprocket on and tack weld in place.

So, I bought a 530/16 tooth counter sprocket for a Honda and started machining. Going to push the hole out some more, but ran out of time today. Next will be turning down the Yamaha sprocket. I need to make a shaft I can put the sprocket on and tack weld in place. They are almost to small diameter to work. I was sliding the chain and sprocket on and couldn't get it to sit all the way against the output shaft spacer. It was being held up by the chain hitting the seal boss. Got my carbide bit out and clearance the seal boss and got it on.

They are almost to small diameter to work. I was sliding the chain and sprocket on and couldn't get it to sit all the way against the output shaft spacer. It was being held up by the chain hitting the seal boss. Got my carbide bit out and clearance the seal boss and got it on.