in my Electronic years ( ham radio stuff) I replaced many components with off the shelf "Close enough" stats.... and they all worked fine

it's amazing what you can get away with in electronics ! I replaced critical components like final amplifier OP amps with larger ones

that should not have worked according to other ham nuts at the time... and it worked just fine with no drifting in frequency ....

My dealings with Motorcycle selenium rectifiers however, was not as successful you would think just replacing them with the proper diodes would do the trick but it didn't happen ! I have no idea what I did wrong ! but it didn't work ! I had to steal a rectifier off a junk bike to make it work again...

.... Alot of automotive electronic components are Very Robust as compared to normal electronics that run on 12 volts, you would think if it's 12vdc its good to use but that's not always the case in many automotive components they have a higher tolerance to High voltage spikes which is what usually takes out the components in the first place.... so when Looking at replacement parts Look at it's ability to withstand transient voltage spikes without damage.... although that is not always possible as most of the time you are given such cryptic information on what the component can do and tolerate that you are left with wondering what their meaning for,Ns, vtn or dsw , or any of the letters that they have in their charts mean !!!!!

Over the years I learned to look for those letters and numbers and although many sites change the letters and numbers to their components

they will have a conversion chart ....most of the time.... if they don't don't buy from them because you have no idea what your getting !

.....but Buying a component that has Higher than the stock component is what I like to do and I've never had that fail.... although things like input voltage 0 to 15vdc must stay the same and not 0 to 5vdc,... going to 0 to 25vdc is ok . and is less likely to burn out over time.

.....

I remember replacing the diodes in an alternator one time by buying the proper diodes at a napa auto parts store... it cost like $5.00 or so ...

I soldered them in there and put the beast back into service and the next month the bearings started going out ! I would have been much better off replacing the bearings at the same time I did the diodes ! .... one of those DUH ! moments ! lol.....

....

Sense the TCI unit is electronic in nature about the only thing that can go wrong with it is being bombarded by high voltage spikes

so make sure all your grounds are clean and not rusty ..... over voltage would have to be very high to damage the TCI unit if what I know is correct

it's built like a tank ! so the only thing you have to worry about is the power, ground and vibration.... the TCI units should outlast the bike and then some..... swapping out a TCI unit's Computer (as some call it) from an old used one should be fine and have a real good chance of working just fine.

just thought I'ed mention that !

replacing components is not rocket science.... even I have done it , and if I can do it anyone can ! LOL

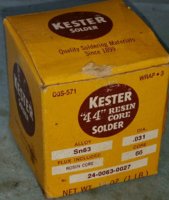

using either Solder Wik, to slirp up the old solder of a vacuum bulb. leaves less excess solder on the board and less chance for a bridged gap somewhere else.... a low wattage soldering iron and an eye for heat.... heat is the enemy of electronics .... make your components secure

in the board by bending the leads on the underside of the board then clip them off.... don't expect the solder to hold them

don't use high temp solder for plumbing ! use electronic solder.....and you'll be fine.

.......

f.w.i.w.

Bob......