-

Enjoy XS650.com? Consider making a donation to help support the site.

XS650.com receives a small share of sales from some links on this page, but direct donations have a much greater impact on keeping this site going.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

5twins has a good pic in this thread post#34

http://www.xs650.com/forum/showthread.php?t=1949&highlight=master+link&page=2

http://www.xs650.com/forum/showthread.php?t=1949&highlight=master+link&page=2

You can use a large nut splitter. I used a dremel tool to cut a shallow "X" in the end of the pins ( a 5twins suggestion if I remember correctly), and then the nut splitter to splay the ends. ummmmmmmmmm, is splay a real word I think I got carried away and splayed mine a little too much but you get the idea.

I think I got carried away and splayed mine a little too much but you get the idea.

I think I got carried away and splayed mine a little too much but you get the idea.

I think I got carried away and splayed mine a little too much but you get the idea.Attachments

I start by tapping an "X" cut into the top of each link pin using a small sharp chisel ....

This keeps the pin in the tool from sliding off the link pin and also allows it to be spread easier .....

I finish up by hand peening it with the round end of a small ball peen hammer .....

I use the cam chain tool from MikesXS. It didn't work very well until I started doing the "X" cut thing. The tool pin kept sliding off one side of the link pin as I tightened it down. The little "X" cut is the secret for getting this tool to work right.

This keeps the pin in the tool from sliding off the link pin and also allows it to be spread easier .....

I finish up by hand peening it with the round end of a small ball peen hammer .....

I use the cam chain tool from MikesXS. It didn't work very well until I started doing the "X" cut thing. The tool pin kept sliding off one side of the link pin as I tightened it down. The little "X" cut is the secret for getting this tool to work right.

luketrash

XS650 Enthusiast

I'm about to do this on a Honda CB350 engine I'm building up. I bought a Tsubaki chain, but at the moment I really don't want to split the cases to install it. So I bought a master link with the chain.

My main question is how in the heck is this a stronger solution to the clip style master link? It just looks like some sort of copper alloy. I understand that there's not much force at the side plates to pull it apart though. With so much room for error depending upon who is installing it, you'd think a clip style would be just as safe when confined to the internals of an engine because there should be nothing for it to ever catch on and come apart.

I don't think there was a clip style master link available from Tsubaki for the chain I got, or I would have opted for it.

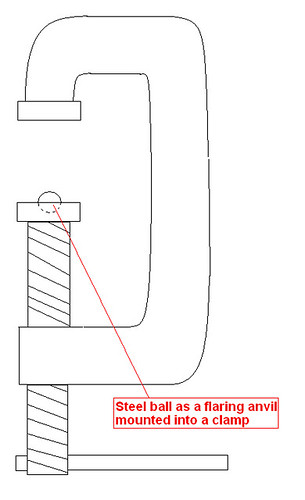

I've been fretting over how to do this ever since. The rivet tools are expensive if you're not buying the 50 dollar Chinese ones from ebay. However, it seems like not really that much pressure is required to flare a rivet style link because the metal is soft? I was thinking of using a C clamp with a modified 'anvil' made out of a ball bearing (since it'd be hardened metal.)

Am I overthinking this? I've read everything from Xing it with a chisel like above to smacking it with a ball peen hammer holding a heavy maul on the other side to deaden the blows?

Then you have people saying you need 300 dollars worth of tools to do this right. A chain press, and some sort of Ducati tech certified tool to press the rivets out to a specific thousandth of an inch if you value your life at all.

So I'm trying to dig through the dirt and figure out what will suit my needs.

So far, this is my three dollar clamp idea:

Does it look stupid?

My main question is how in the heck is this a stronger solution to the clip style master link? It just looks like some sort of copper alloy. I understand that there's not much force at the side plates to pull it apart though. With so much room for error depending upon who is installing it, you'd think a clip style would be just as safe when confined to the internals of an engine because there should be nothing for it to ever catch on and come apart.

I don't think there was a clip style master link available from Tsubaki for the chain I got, or I would have opted for it.

I've been fretting over how to do this ever since. The rivet tools are expensive if you're not buying the 50 dollar Chinese ones from ebay. However, it seems like not really that much pressure is required to flare a rivet style link because the metal is soft? I was thinking of using a C clamp with a modified 'anvil' made out of a ball bearing (since it'd be hardened metal.)

Am I overthinking this? I've read everything from Xing it with a chisel like above to smacking it with a ball peen hammer holding a heavy maul on the other side to deaden the blows?

Then you have people saying you need 300 dollars worth of tools to do this right. A chain press, and some sort of Ducati tech certified tool to press the rivets out to a specific thousandth of an inch if you value your life at all.

So I'm trying to dig through the dirt and figure out what will suit my needs.

So far, this is my three dollar clamp idea:

Does it look stupid?

Last edited:

I'm sure you could use a modded C-clamp, just try to find one with a fine threaded screw. I bought the #35-0112 tool from Mike's because I knew I would be using it more than once. I've done near half a dozen chains as above and so far, all are holding up fine. I figured they would because I think this method produces better results than the factory gave you. Here's a factory rivet job, see what I mean? .....

Yes, I back the chain/sprocket up with a block of wood or something while peening with the hammer. For removal of the old link, I grind the riveted ends off and then the link pops right out with a couple taps on the pins using a drift .....

Yes, I back the chain/sprocket up with a block of wood or something while peening with the hammer. For removal of the old link, I grind the riveted ends off and then the link pops right out with a couple taps on the pins using a drift .....

luketrash

XS650 Enthusiast

Holy cow. I haven't had my XS650 opened up yet. I've never seen anything like that on my Honda bikes. OK, I'm not so worried then. It looks like there are 100 ways to tackle the project.

When I originally thought of the concept of riveting a chain, I was thinking the link had to be as durable as the one next to it with the steel pin staked from two or four sides.

Thanks for posting the factory photo. That's kind of humorous.

When I originally thought of the concept of riveting a chain, I was thinking the link had to be as durable as the one next to it with the steel pin staked from two or four sides.

Thanks for posting the factory photo. That's kind of humorous.

luketrash

XS650 Enthusiast

Ok, so on bicycles, I have always used a pin pusher tool to push the pin of one link out of the chain. Then I used the same tool to push the pin back into place and you wiggle the chain to loosen that link back up so it is flexible.

Last night I did the same thing to my Tsubaki chain I am putting in my Honda engine. Is this an acceptible practice? I had no problem pushing one of the link pins out of the chain with my Park Tools bicycle chain tool. And I had no problem pushing it back into place. Everything seems tight. Only one link pin is affected rather than two..

However, I have not read about anyone doing this, so I'm wanting to check before I put the engine together.

luketrash

XS650 Enthusiast

It seems like since everything is hardened steel that the end retains its slight mushrooming. Or at least it's so tight it'll never shake out because you have to use the tool just to push it back in. Also, the other half of that link is staked together by a link that has never been disturbed, so the side pieces aren't likely to move or spin separate of each other.

I mashed down on the link with some big vice grips. I think I'm going to call it safe and run with it. I'm just surprised to have never seen it mentioned as an option. That's how people typically service bicycle chains or change the length of them when putting a new one on.

I ended up cutting the back of a drill bit of appropriate size to make my 'pusher' piece. It worked great since it was also hardened steel.

I mashed down on the link with some big vice grips. I think I'm going to call it safe and run with it. I'm just surprised to have never seen it mentioned as an option. That's how people typically service bicycle chains or change the length of them when putting a new one on.

I ended up cutting the back of a drill bit of appropriate size to make my 'pusher' piece. It worked great since it was also hardened steel.

In the Honda book I have they use vise grips to peen the master link.

I started my master link that way, just enough so the sideplate stayed there so I could peen the pins. Ball peen to hit the pins, a three pound hammer to back up the pins.

In one book they show peening the pins using a bolt cutter. The pic 5twins showed looks like it was done that way.

A clip style mater link on the inside of an engine,I don't think I'd do that. If the clip ans side plate came off think of the possible damage.

I started my master link that way, just enough so the sideplate stayed there so I could peen the pins. Ball peen to hit the pins, a three pound hammer to back up the pins.

In one book they show peening the pins using a bolt cutter. The pic 5twins showed looks like it was done that way.

A clip style mater link on the inside of an engine,I don't think I'd do that. If the clip ans side plate came off think of the possible damage.

Rabbidmk1

XS650 Enthusiast

Ok guys I'm bringin this one back from the dead. I understand how to peen the links and I already bought the tool from mikes. My question though, is how do you even get the outer plate onto the master link? From what I can tell, the 256 chain link needs to be pressed on and then peened? Any suggestions?

Thanks!

Thanks!

On the chains I've done the pins are slightly smaller on the ends where the plate goes on. The shoulder formed where the diameter changes keeps you from over peening the pin so as to make a tight spot.

The plate is a snug fit bit they slip on, maybe use a pair of pliers to push them on.

Leo

The plate is a snug fit bit they slip on, maybe use a pair of pliers to push them on.

Leo

Similar threads

Sold / Found / Inactive -

Cam Chain Masterlink and Guide/Stopper for 447s

- Monterey, CA

- Replies

- 1

- Views

- 81

- Replies

- 9

- Views

- 413