funky

XS650 Junkie

Hi all its been a while hope you are all well .

My XS started burning oil the old 75mm sleeves had been rebored to the max 77.5mm... not sure if the could go any further but 707cc pistons were now too small ring gap was at the top end of tolerance at the last rebuild.

Yes I have bit the bullet and have gone for the 750 big bore from heiden tuning, my old cylinder will be re sleved back to 650cc my next project after the big bore and shelved for the future.

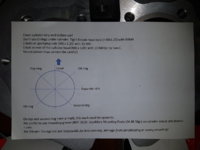

The big bore kit is already prepared and ready to fit ......so stripped the engine and cleaned and preped the head, lapped the Valves and fitted new Valve stem oil seals ready for the kit to arrive.

Not sure what to expect in terms of performance but looking forward to the rebuild any advise would be welcomed as allways .

All the best Funky

My XS started burning oil the old 75mm sleeves had been rebored to the max 77.5mm... not sure if the could go any further but 707cc pistons were now too small ring gap was at the top end of tolerance at the last rebuild.

Yes I have bit the bullet and have gone for the 750 big bore from heiden tuning, my old cylinder will be re sleved back to 650cc my next project after the big bore and shelved for the future.

The big bore kit is already prepared and ready to fit ......so stripped the engine and cleaned and preped the head, lapped the Valves and fitted new Valve stem oil seals ready for the kit to arrive.

Not sure what to expect in terms of performance but looking forward to the rebuild any advise would be welcomed as allways .

All the best Funky

sorted the head out lapped in the valves

sorted the head out lapped in the valves

But this does have it down falls I have made big mistakes

But this does have it down falls I have made big mistakes  But I suppose thats how you learn

But I suppose thats how you learn

I am fitting the 750cc Big bore kit and will be using my BS34 stock carbs which i was running on my 707cc engine

I am fitting the 750cc Big bore kit and will be using my BS34 stock carbs which i was running on my 707cc engine

and should take a chill pill

and should take a chill pill

out of me

out of me